Power grid intelligent scheduling operation order generation system

A technology for intelligent scheduling and generation of systems, applied in information technology support systems, printing, instruments, etc., to solve problems such as lack of objective security means and security risks of remote operation of power grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

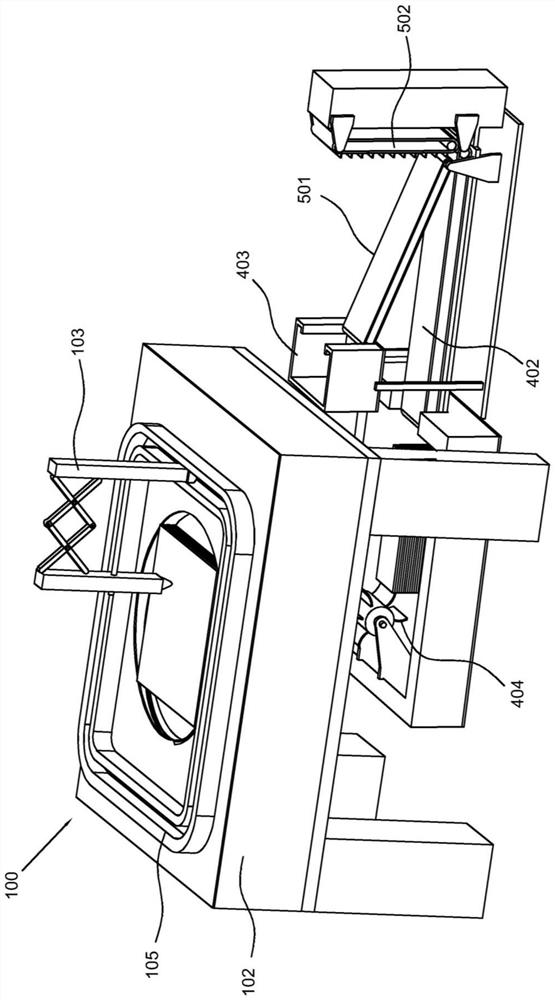

[0030] refer to figure 1 and Figure 7 , a power grid intelligent dispatching operation ticket generation system, comprising, an operation ticket generation component, including a first receiving unit, a check request file generation module connected to the first receiving unit, and a sending unit, the sending module is provided with a second receiving unit Unit; printing assembly 100, including operating platform 101, printing platform 102 electrically connected with operating platform 101, and drawing piece 103 arranged on printing platform 102, printing platform 102 is provided with drawing paper 104; And, finishing assembly 400, finishing The assembly 400 is arranged at the lower end of the printing assembly 100, and the second receiving unit is provided with an analysis unit, and the analysis unit is provided with a dispatching and ticketing unit.

[0031] Specifically, the subject of the present invention includes an operation ticket generation component, and the operat...

Embodiment 2

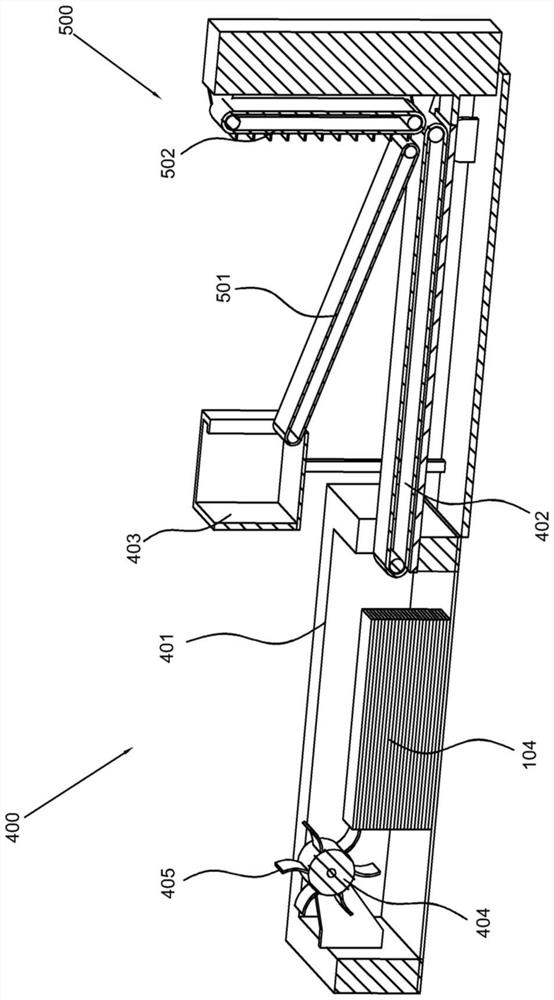

[0037] refer to Figure 1-6 , This embodiment is different from the first embodiment in that: the finishing assembly 400 includes a transportation slot 401 provided on the printing platform 102, a conveyor belt 402 arranged in the transportation slot 401, and a receiving box 403 arranged near the printing platform 102 The transport trough 401 is located at the conveyor belt 402 and is also rotatably connected with a dial 404, and a plurality of dials 405 are arranged on the dial, wherein, the receiving box 403 is provided with a receiving part 500, and the receiving part 500 includes a first turning belt arranged obliquely 501, the first reversing belt 501 is arranged obliquely, and the end of the first reversing belt 501 away from the receiving box 403 is provided with a second reversing belt 502. A slight gap is formed between the first reversing belt 501 , the second reversing belt 502 and the conveying belt 402 , and the conveying directions of the first reversing belt 501...

Embodiment 3

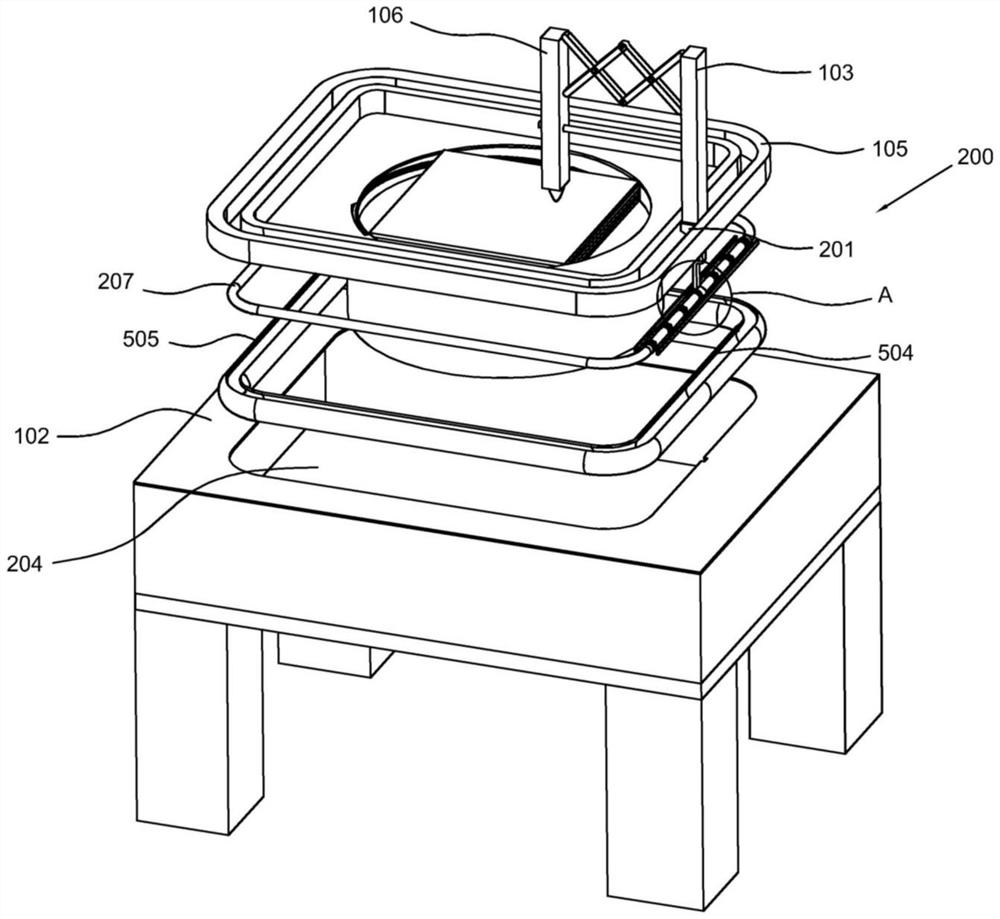

[0043] refer to Figure 1-6 , this embodiment is different from the above embodiments in that: the printing assembly 100 also includes a guide rail 105 arranged on the printing platform 102, the guide rail 105 is arranged circularly on the printing platform 102, and the upper end of the drawing part 103 is bent downward to form a pen tip part 106, The lower end of the drawing part 103 is provided with a driving part 200, and the driving part 200 includes a running wheel 201 arranged at the lower end of the drawing part 103, a rotating shaft 202 protruding from the center of rotation of the running wheel 201, and a shaft 202 cooperating with the rotating shaft 202 provided on the side wall of the guide rail 105. The ring groove 203, wherein, the printing platform 102 is provided with a placement cavity 204, the placement cavity 204 is connected to the guide rail 105, the rotating shaft 202 is provided with a guide rod 205, the lower end of the guide rod 205 is provided with a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com