Crystal composite fiber with porous sound absorption structure and preparation method thereof

A technology of composite fibers and crystals, applied in the field of sound-absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

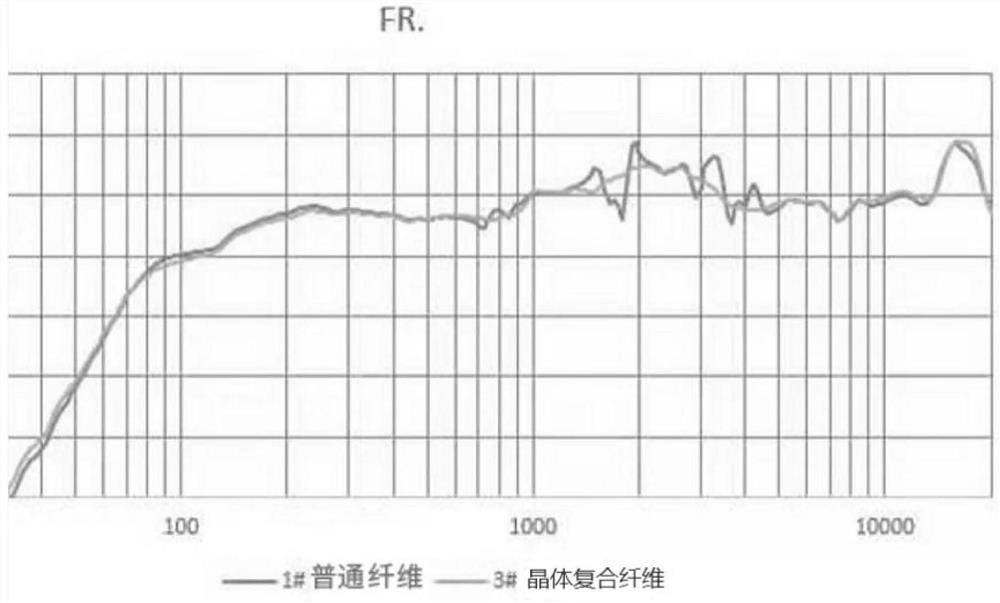

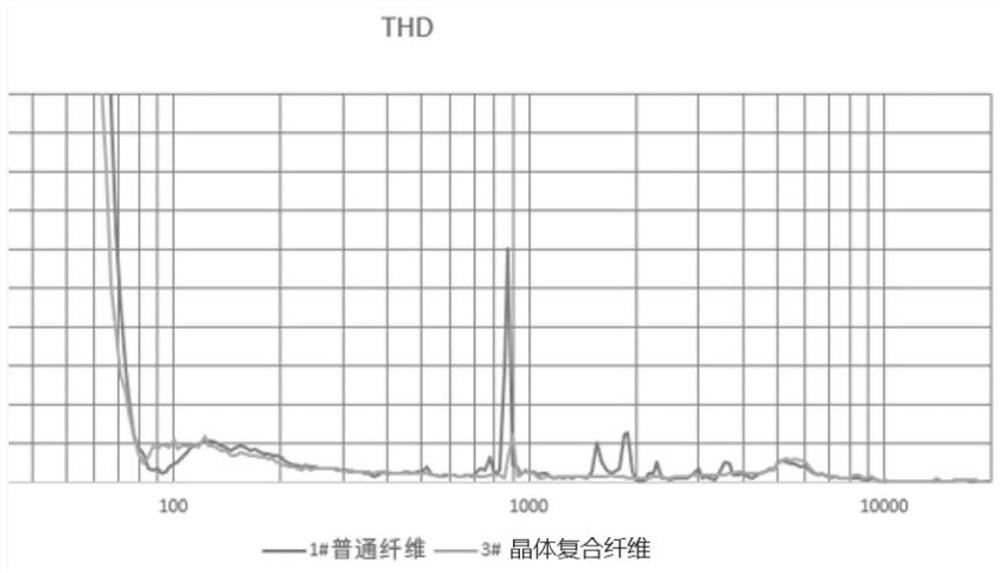

[0018] see Figure 1-2 As shown, the present invention relates to a crystal composite fiber with a porous sound-absorbing structure, including a crystal composite fiber body with a three-dimensional network structure, and the crystal composite fiber body has several sound-absorbing gaps; wherein the weight parts of the raw materials of the crystal composite fiber body The ratio is 100 parts of polypropylene PP1500 raw material and 5 parts of polypropylene Z30S raw material.

[0019] In order to achieve the above object, the technical solution adopted in the present invention is: a method for preparing a crystal composite fiber with a porous sound-absorbing structure, comprising the following steps:

[0020] Step S1, weighing the polypropylene PP1500 raw material and the polypropylene Z30S raw material according to the composition ratio in parts by weight and fully mixing them;

[0021] Step S2, plasticizing the mixed raw materials through an extruder;

[0022] Step S3, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com