Horizontal draught automobile carburetor capable of achieving uniform mixing

A uniform mixing and flat suction technology, which is applied to carburetors, machines/engines, engine components, etc., can solve the problem of poor mixing effect, poor control of fuel atomization and oil intake, and poor observation of carburetion problems such as the amount of fuel in the engine, to achieve the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

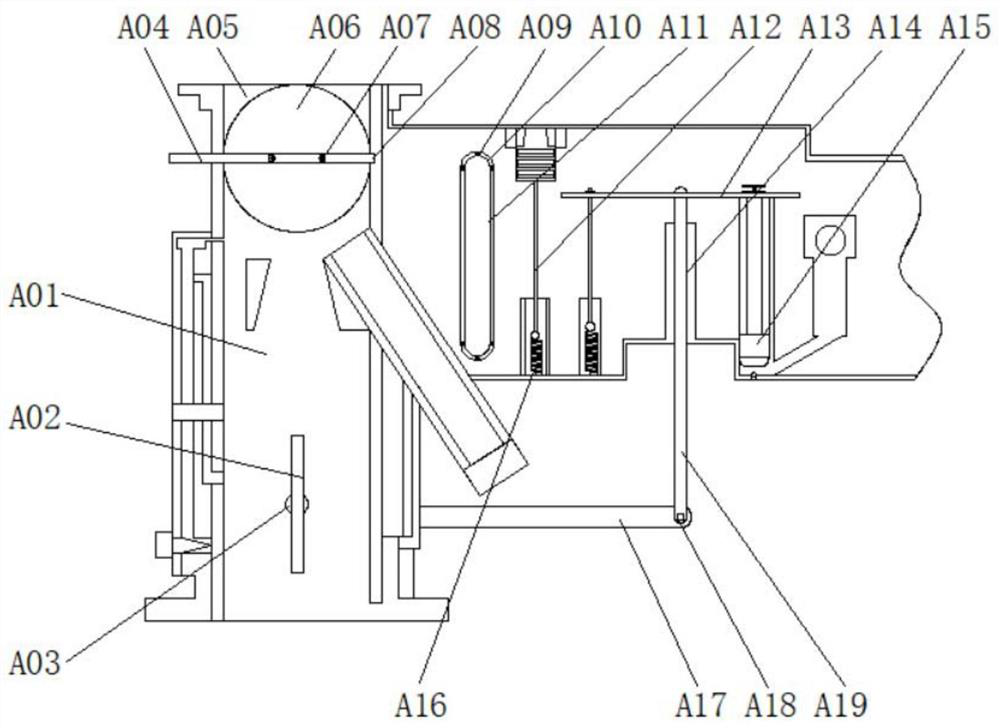

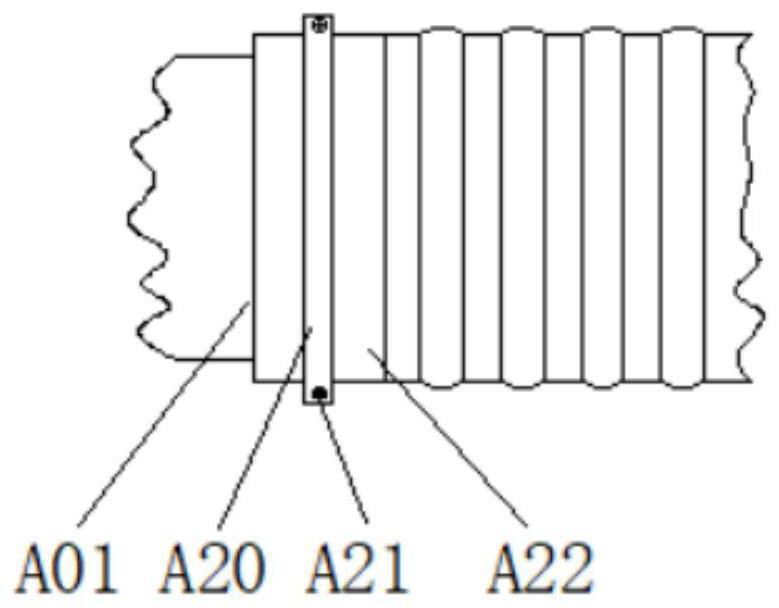

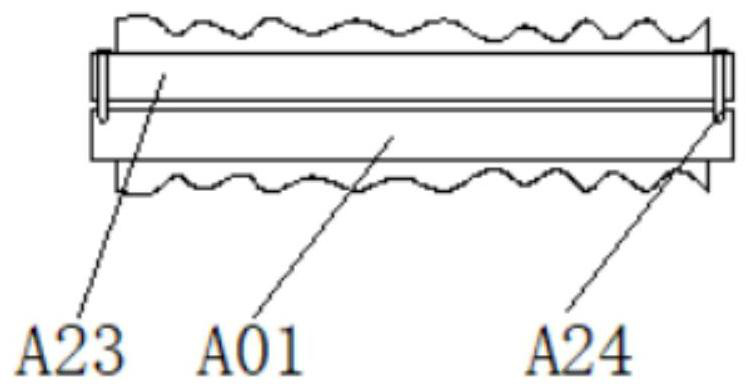

[0024] see Figure 1-4, a flat-suction automobile carburetor capable of uniform mixing, including a main housing A01, a blocking plate A02, a pin shaft A03, a rotating rod A04, an air inlet A05, a flap A06, a locking screw A07, a chute A08, Limiting screw A09, pressing piece A10, glass A11, floating piston A12, connecting rod A13, guide groove A14, accelerating piston A15, spring A16, inclined rod A17, locking pin A18, pull rod A19, fixing clip A20, fixing scr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap