Engine compressed air supply system, engine and engine control method

A technology of compressed air and control methods, applied in engine control, electrical control, engine components, etc., can solve problems such as difficult balance between fuel economy and cost control, affect engine fuel economy, and complex engine mechanical structure, etc., to achieve flexible design Convenience, flexible development margin, and the effect of increasing the injection duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

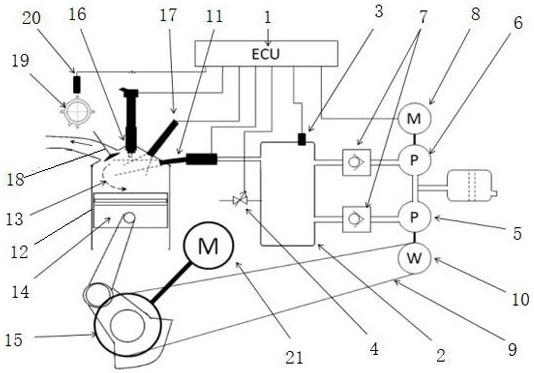

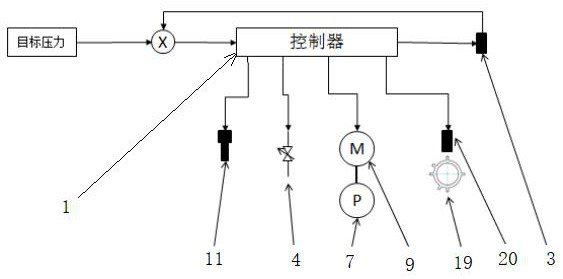

[0027] In an example, as Figure 1~Figure 2 shown,

[0028] An engine applying direct injection in a cylinder of an engine compressed air supply device, including an engine compressed air supply system, the engine compressed air supply system comprising an electronic control module 1 and an air storage tank 2, and the tank body of the air storage tank 2 is provided with The pressure sensor 3 and the pressure maintaining valve 4 are electrically connected to the electronic control module 1. The pressure sensor 3 detects the pressure value in the gas storage tank 2, and transmits the pressure value signal to the electronic control module 1, so that the electronic control module can detect the pressure value of the device. The various components of the air conditioner are organically regulated, and the electronic control module controls the air pressure in the air storage tank 2 within the pressure range suitable for the working load of the engine by controlling the switching of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com