A four-way hydraulic transformer with shaft distribution structure

A four-way hydraulic and transformer technology, which is applied in the field of hydraulic components, can solve the problems of large volume of the distribution structure, increase the friction of the distribution surface, and affect the balance of the distribution plate, so as to improve the volumetric efficiency, reduce the axial impact and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

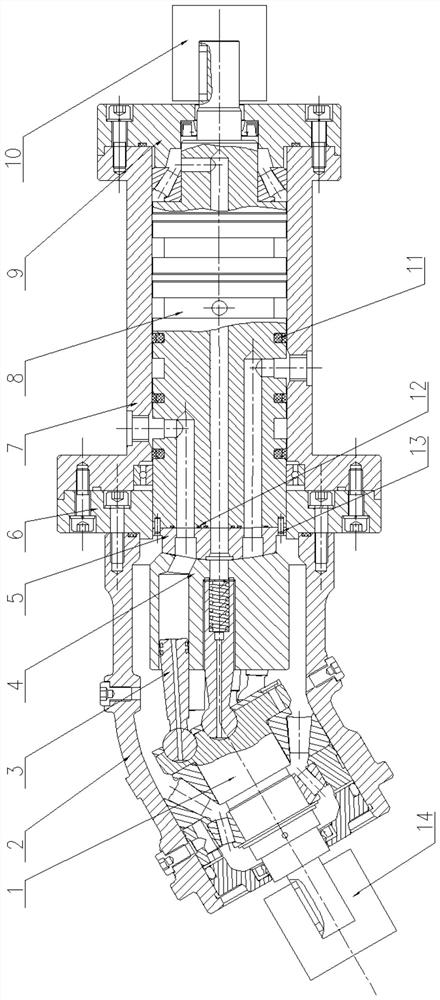

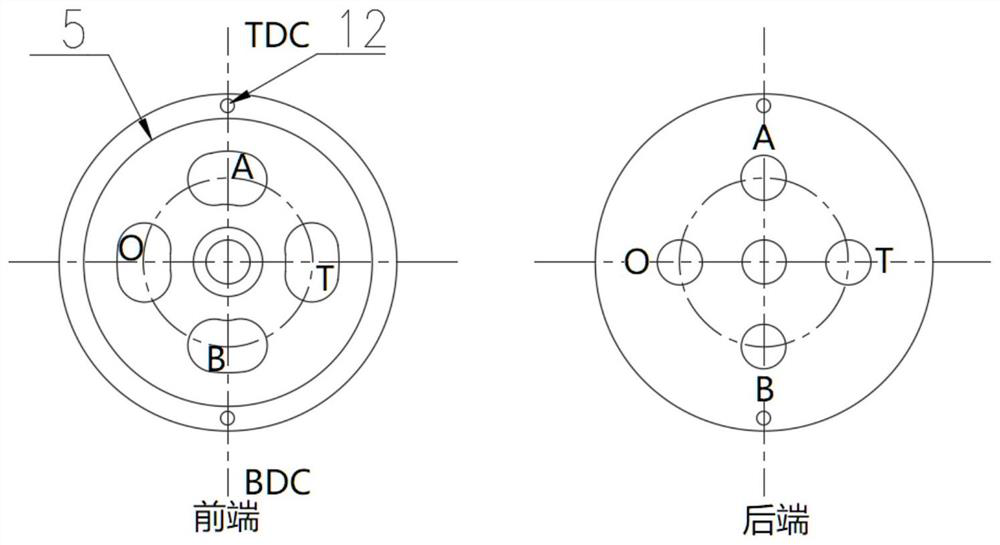

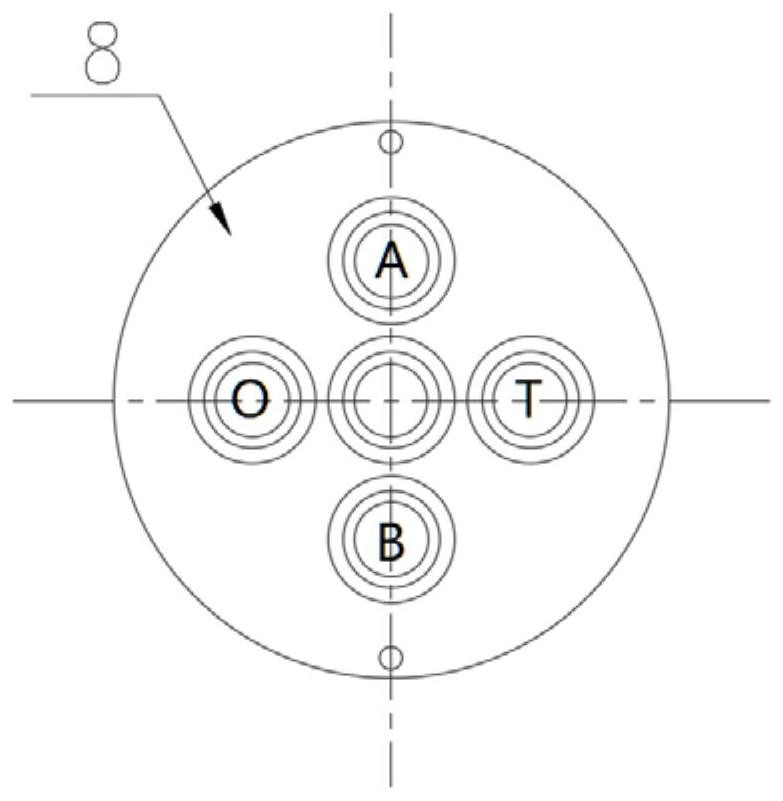

[0017] like figure 1 As shown, a distribution shaft type four-way hydraulic transformer includes a main shaft 1; a hydraulic transformer housing 2; a plunger 3; a cylinder block 4; a distribution plate 5; a transition plate 6; a distribution shaft housing 7; a distribution shaft 8; End cover 9; Servo motor 10; Rotary Gree ring 11; O-ring 12; Pin shaft 13; Rotary encoder 14. The main shaft 1, the plunger 3, and the cylinder block 4 are fixed in the transformer housing 2 through bearings. One end of the cylinder block 4 is attached to the front end of the distribution plate 5 through an oil film. The distribution plate 5 has four waist-shaped grooves 5-1. The center of the waist-shaped groove 5-1 is provided with a through-flow distribution plate flow channel 5-2, the inside of the distribution shaft 8 is opened with a corresponding distribution shaft flow channel 6-1, and the rear end of the distribution plate 5 is connected with the distribution shaft 8 through the pin shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com