Multi-station three-dimensional laser scanning internal measurement device and method for volume of vertical tank with large length-diameter ratio

A technology of three-dimensional laser and large aspect ratio, which is applied in the field of three-dimensional laser scanning, can solve the problems of low measurement accuracy, affect volume measurement accuracy, and inability to measure, and achieve the same point cloud data accuracy, improve measurement accuracy, and improve calculation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

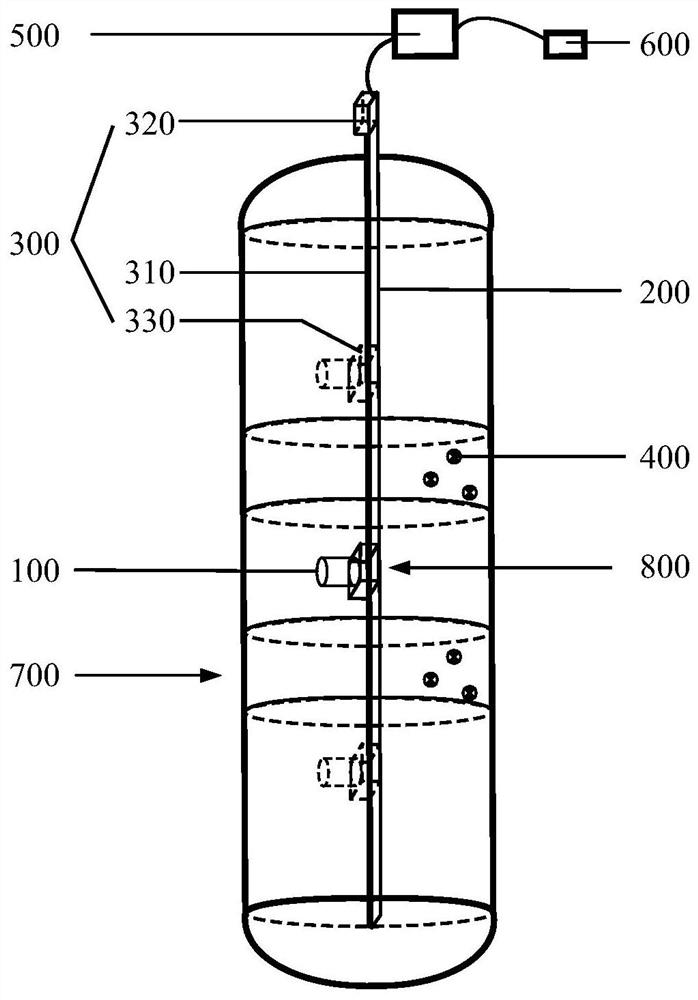

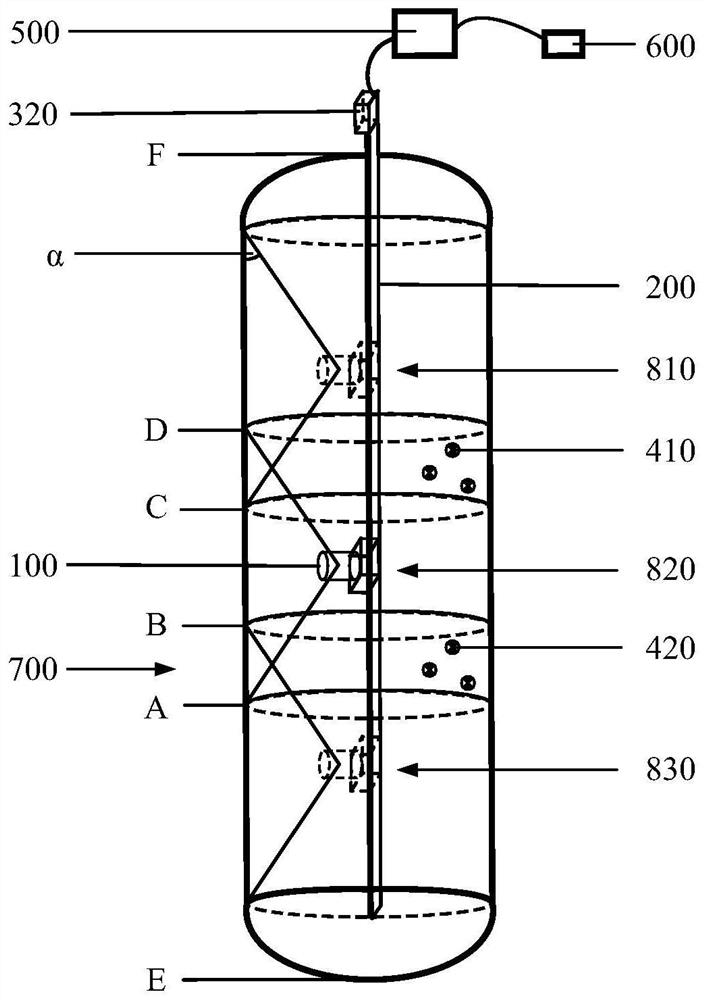

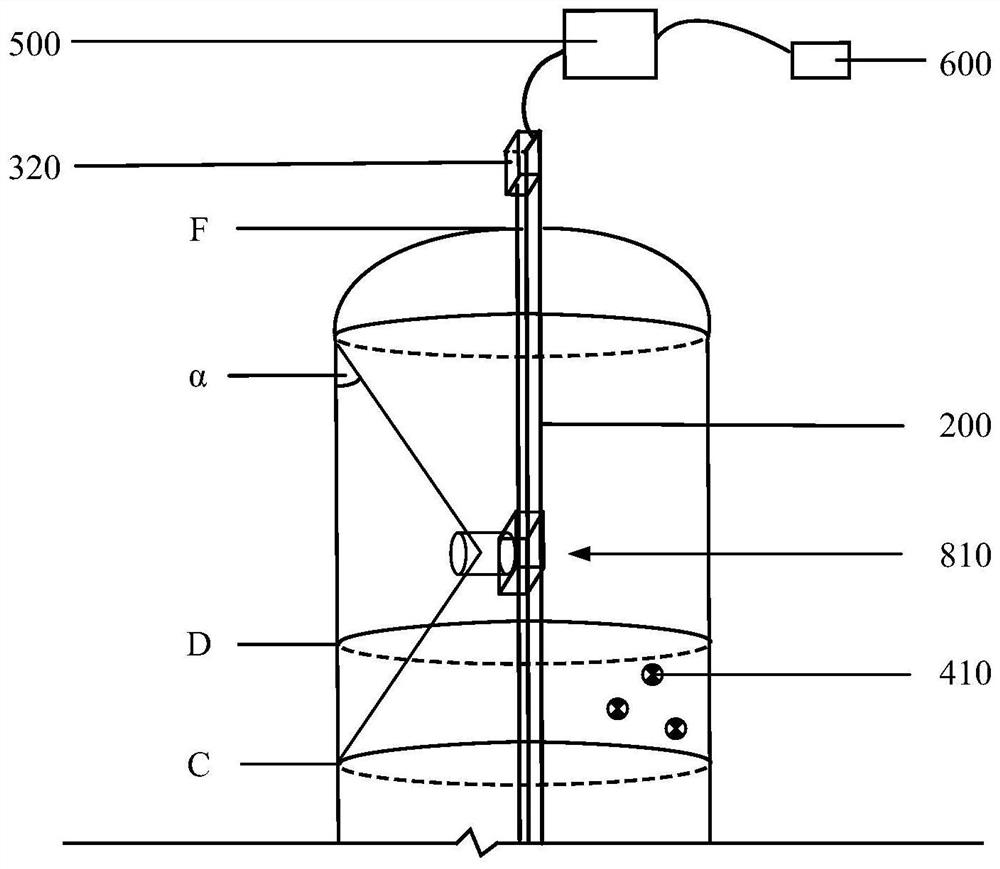

[0037] The invention provides a multi-station three-dimensional laser scanning internal measurement device for vertical tank volume with large length-to-diameter ratio, see Figure 1-Figure 3 , including a laser scanner 100 , a guide rail 200 and a transmission assembly 300 , wherein the transmission assembly 300 is arranged on the guide rail 200 and can slide along the length direction of the guide rail 200 , and the laser scanner 100 is arranged on the transmission assembly 300 . When in use, the transmission assembly 300 is used to drive the laser scanner 100 to move along the length direction of the guide rail 200. During the movement, a plurality of stations 800 are set, and the laser scanner 100 opposes 700 vertical tanks at the station 800. Each part is scanned to obtain point cloud data, and the processor 600 is set outside the tank to receive the measurement data of the laser scanner, perform filtering, splicing and other processing on the data, and calculate the verti...

Embodiment 2

[0052] A multi-station three-dimensional laser scanning internal measurement method for the volume of a vertical tank with a large aspect ratio, using the above-mentioned multi-station three-dimensional laser scanning internal measurement device for a vertical tank with a large aspect ratio, combined with Figure 2-Figure 5 , including the following steps:

[0053] Step 1. Install one end of the guide rail 200 inside the vertical tank 700 along the axis of the vertical tank 700, and install the splicing target 400 in the vertical tank 700, including the first station 810 and the second station 820 the first mosaic target 410 within the common scan range and the second mosaic target 420 within the common scan range of the second station 820 and the third station 830;

[0054] Step 2, control the precision servo motor 320 to work, drive the laser scanner 100 to move into the vertical tank 700, and set a number of measuring stations 800 at intervals during the process;

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com