Full-automatic indentation measuring device and method

A technology of measuring device and measuring method, applied in the direction of measuring device, testing material hardness, image enhancement, etc., can solve the problems of low efficiency, cumbersome method, indentation error can not meet the requirements and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

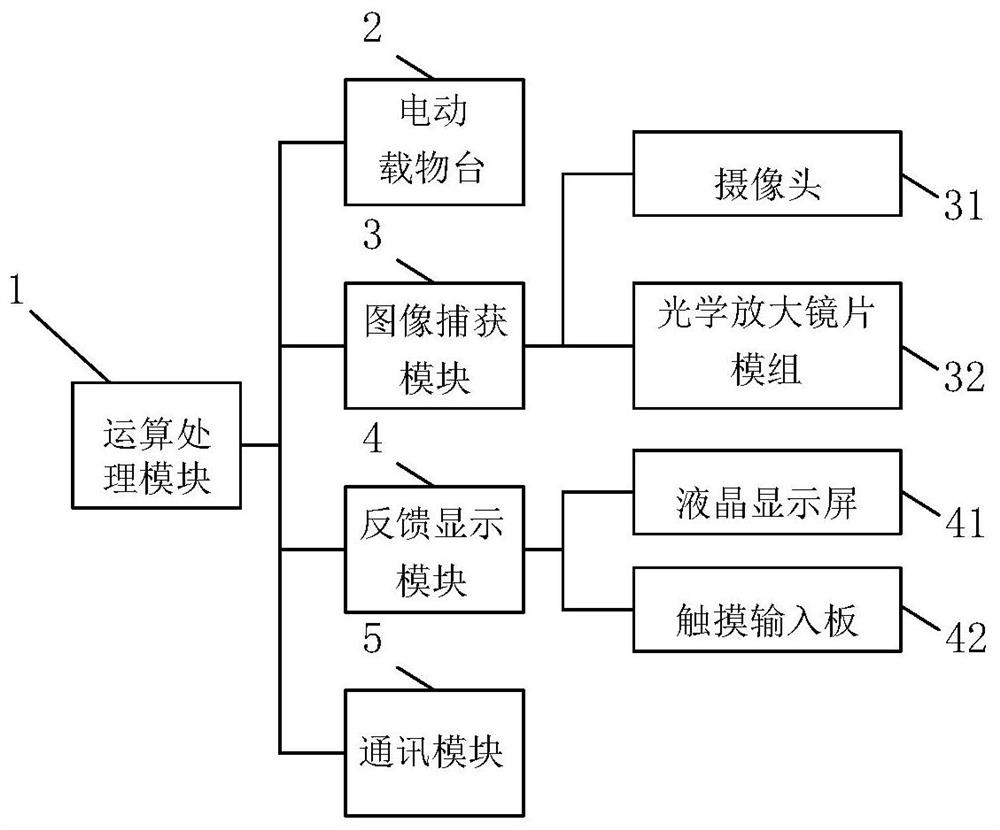

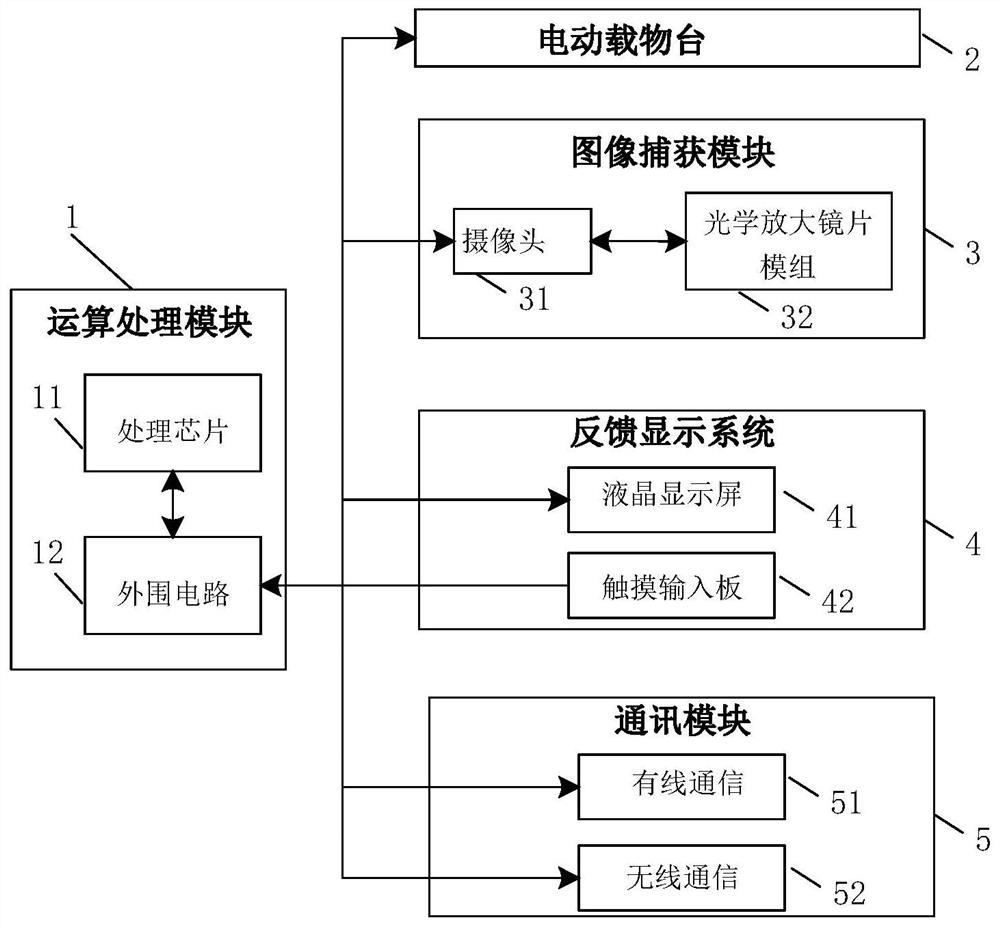

[0079] Such as figure 1 and figure 2 As mentioned above, this embodiment discloses a fully automatic indentation measurement device, including an electric stage, an image capture module and an operation processing module; the electric stage and the image capture module are all connected to the operation processing module;

[0080] The electric stage is used to place (carry) the object to be measured; and receive instructions from the computing processing module, and complete the functions of translation and lifting through the motor drive, so that the object to be measured on it is in the field of view of the image capture module within the range and keep in focus;

[0081] The image capture module is used to acquire the image of the object to be measured placed on the electric stage, and transmit the image to the operation processing module;

[0082] The operation processing module is used to acquire and process the images acquired by the image capture module, perform the ...

Embodiment 2

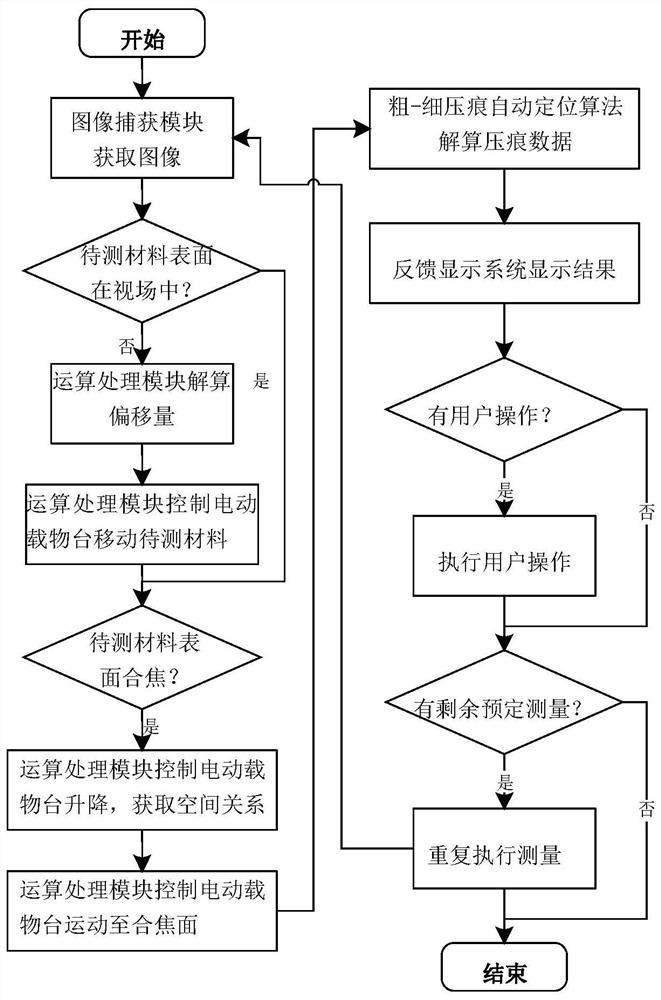

[0092] Such as image 3 As shown, this embodiment discloses a fully automatic indentation measurement method, using the fully automatic indentation measurement device described in Example 1 to perform indentation measurement, including the following steps:

[0093] Step 1. The image capture module acquires the surface image of the object to be measured placed on the motorized stage, and transmits it to the operation processing module;

[0094] Step 2. Based on the image acquired by the image capture module, the operation processing module controls the horizontal movement of the motorized stage so that the surface of the object to be measured is in the field of view of the image capture module, and controls the lifting of the motorized stage so that the surface of the object to be measured is in the image The focal plane of the capture module;

[0095] The operation processing module controls the lifting of the motorized stage, so that the surface of the object to be measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com