Wafer cutting method

A cutting method and wafer technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of low wafer throughput, burns of the UV film supporting the wafer, insufficient cutting time, etc. The effect of precise control of cutting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

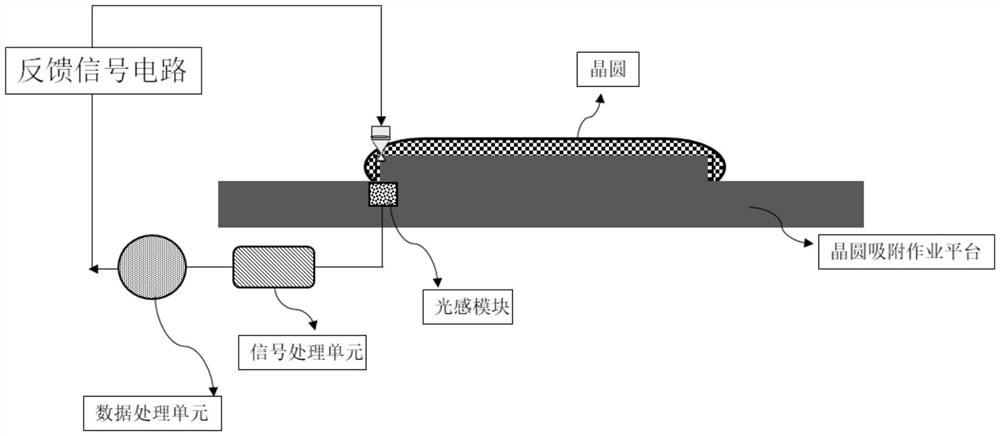

[0015] The wafer cutting method described in the present invention is mainly aimed at ring cutting of the wafer. According to the principle of dicing, the thickness of the dicing part gradually becomes thinner during dicing, which causes the light transmittance of the wafer to change. like figure 1 As shown, the entire cutting system includes a cutting head to realize circular cutting of the wafer, and also includes a photosensitive module, a signal processing unit, a data processing unit, and a feedback signal circuit. When the dicing unit ring-cuts the wafer, a photosensitive module is arranged under the wafer. Specifically, after the wafer is adsorbed on the cutting table, the photosensitive module is installed directly below the area with a radius of 130-150mm of the wafer. The photosensitive module and the cutting head are placed opposite to each other on both sides of the wafer. The number of photosensitive modules is set to 1 ~10, can realize simultaneous monitoring o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com