Rockburst tunnel section primary support method and support anchor rod structure

A technology of primary support and bolt, which is applied in the installation of bolt, earthwork drilling, wellbore lining, etc. It can solve problems affecting construction progress, hidden dangers of construction safety, and ejection of rock blocks, so as to save investment, enhance integrity, Avoid the effect of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

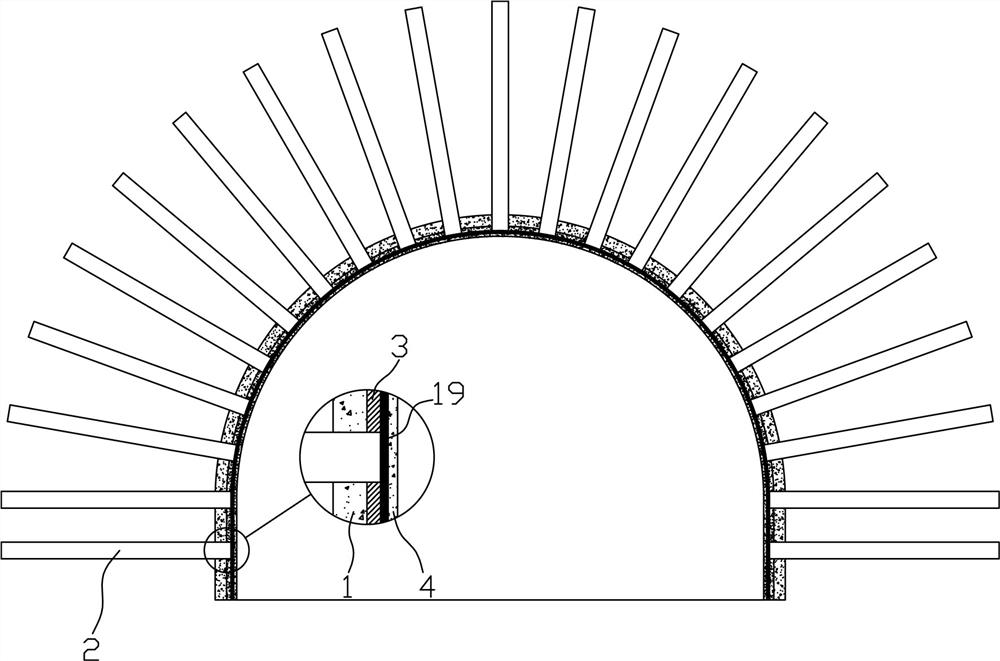

[0035] The initial support method for the rockburst tunnel section includes the following steps:

[0036] 1) Carry out hole excavation along the excavation direction;

[0037] 2) Clean the rock surface of the cavern section after excavation;

[0038] 3) Spray concrete to the rock face and form the first concrete layer 1;

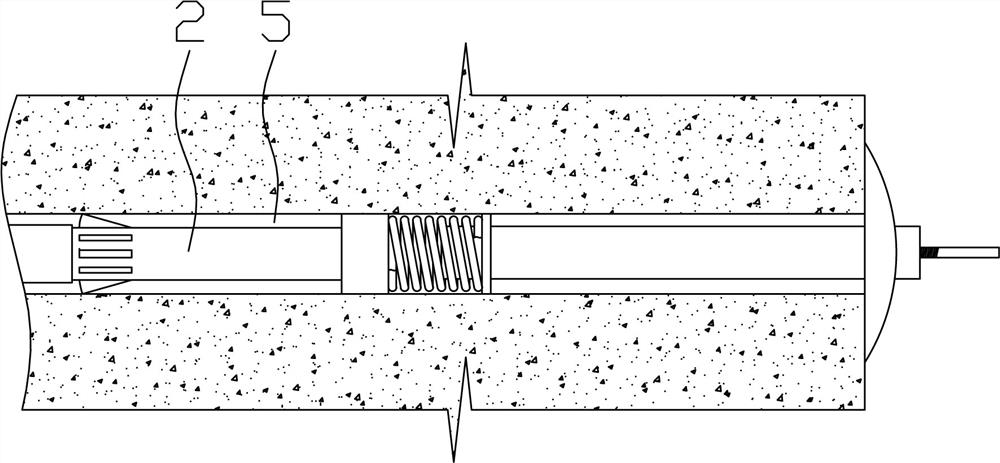

[0039] 4) Drill anchor holes 5 extending to the rock body on the surface layer of the first concrete layer 1;

[0040] 5) Install anchor rod 2;

[0041] 6) Lay reinforcement mesh 3 on the surface layer of the first concrete layer 1;

[0042] 7) Connect the exposed part of the anchor rod 2 through the connecting rib 19, and spot welding is used for the connecting position;

[0043] 8) Spraying concrete on the surface of the first concrete layer 1 to form the second concrete layer 4;

[0044] 9) Repeat steps 1)-8) to complete the hole excavation construction.

[0045] In a preferred solution, in step 5), after the installation of the anchor rod 2 is comp...

Embodiment 2

[0053] On the basis of Embodiment 1, the connecting rib 19 includes an axial connecting rib 191 and a radial connecting rib 192. The axial connecting rib 191 connects the ends of a plurality of anchor rods 2 along the axial direction of the cavity, and the radial connecting rib 192 The connecting rib 192 connects the ends of multiple anchor rods 2 along the radial direction of the cavity.

[0054] In a preferred solution, the axial connecting ribs 191 are arranged in an "X" shape along the axial direction of the cavity, the axial connecting ribs 191 and the radial connecting ribs 192 are spot welded at the intersecting positions, and the axial connecting ribs 191 and the radial The connecting ribs 192 are welded to the connecting ribs 19 to form triangular holes for strengthening the strength of the connecting ribs 19 .

Embodiment 3

[0056] On the basis of embodiment 1,

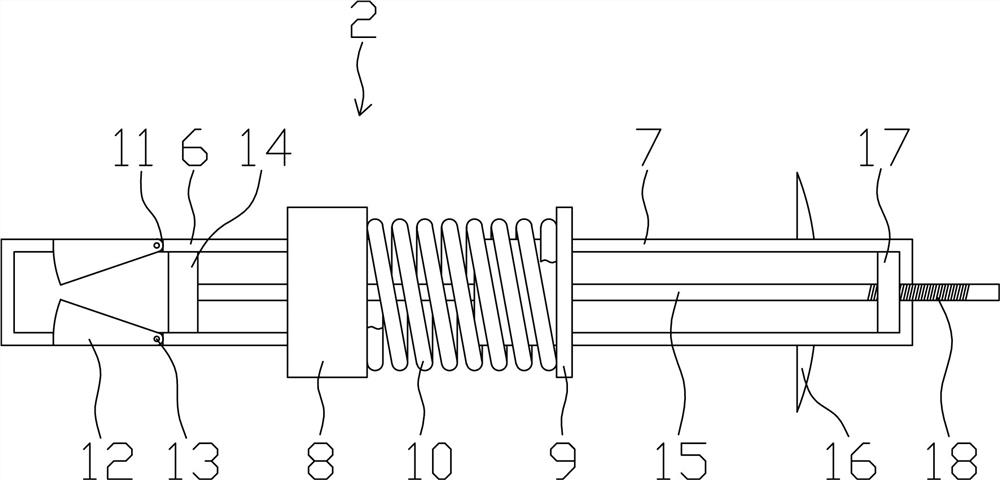

[0057] The support bolt used for the initial support method of the above-mentioned rockburst tunnel section has the following specific structure:

[0058] The anchor 2 includes a first anchor section 6 and a second anchor section 7, and both the first anchor section 6 and the second anchor section 7 are hollow structures;

[0059] One end of the first anchor section 6 is an anchor head, and the other end is provided with a first fixing seat 8;

[0060] The second anchor section 7 is fixed with a second fixing seat 9 on the part of the outer wall located in the surrounding rock, and a backing plate 16 is provided on the outer wall of the second anchor section 7 near the other end;

[0061] An energy release spring 10 is arranged between the first fixing seat 8 and the second fixing seat 9 , and both ends of the energy releasing spring 10 are respectively fixed on the first fixing seat 8 and the second fixing seat 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com