Clamping chain type connecting device for large-diameter vacuum flange butt joint

A vacuum flange and connecting device technology, applied in flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of high radiation on the surface of the material, time-consuming and laborious installation and disassembly, and potential safety hazards, etc. The effect of radiation pollution, simple and convenient operation, and shortening of disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

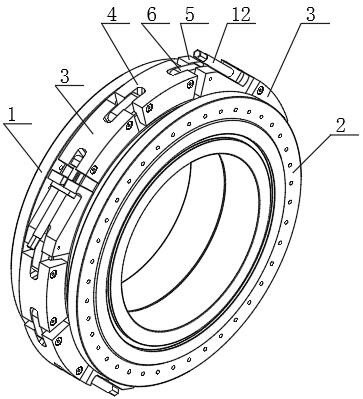

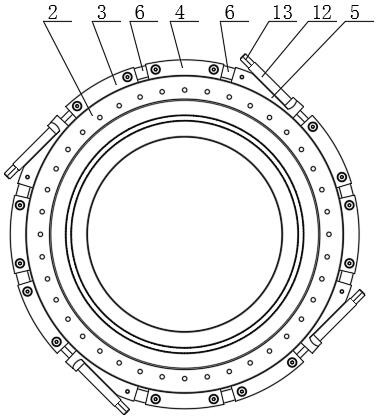

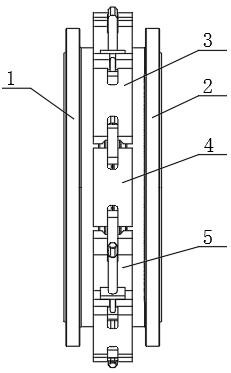

[0026] Such as Figure 1~3 As shown, a clip chain connection device for large-diameter vacuum flange butt joints, including four split components, each split component includes three arc-shaped snap-in blocks, and the adjacent snap-in blocks are hinged to each other The clamping blocks are sequentially connected end to end to form a ring, and the head clamping block 3 and the tail clamping block 5 of two adjacent split components are detachably connected. The inner diameter of the ring of the connecting device is smaller than the diameter of the vacuum flange, and the outer diameter of the ring is larger than the diameter of the vacuum flange. The inner wall of the clamping block is provided with a trapezoidal groove 7, and the clamping block is clamped between two flanges through the trapezoidal groove 7. Such as Figure 8 As shown, the outer edges of the two vacuum fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com