Composite base material, preparation method of composite base material, battery and electric vehicle

A composite substrate, electric vehicle technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve problems such as inability to directly use metal current collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

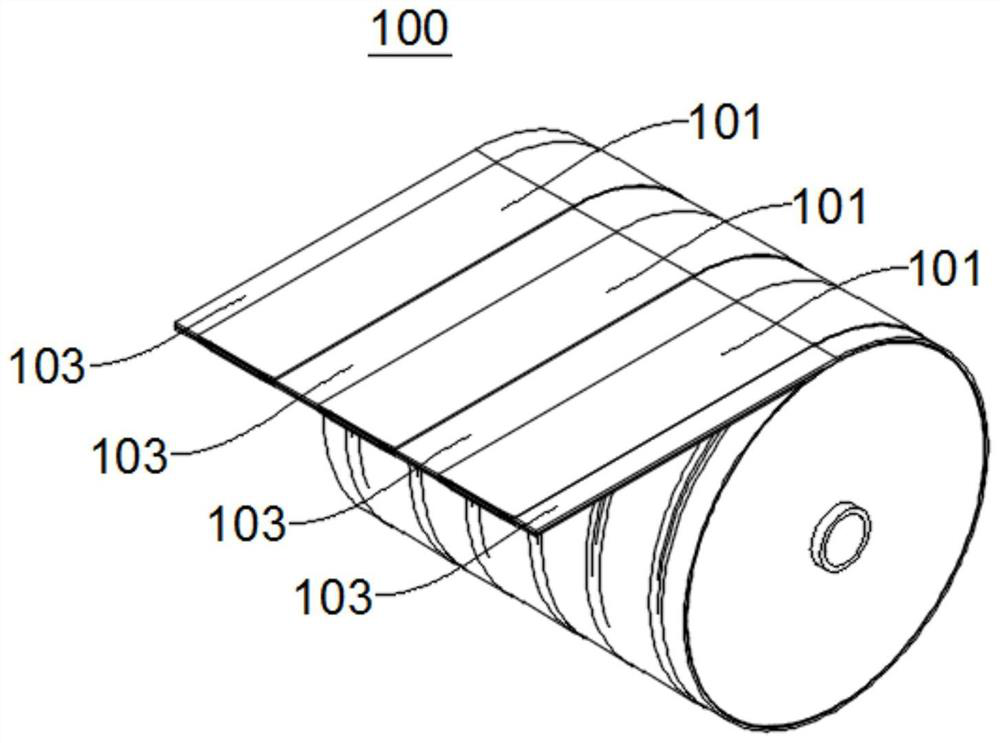

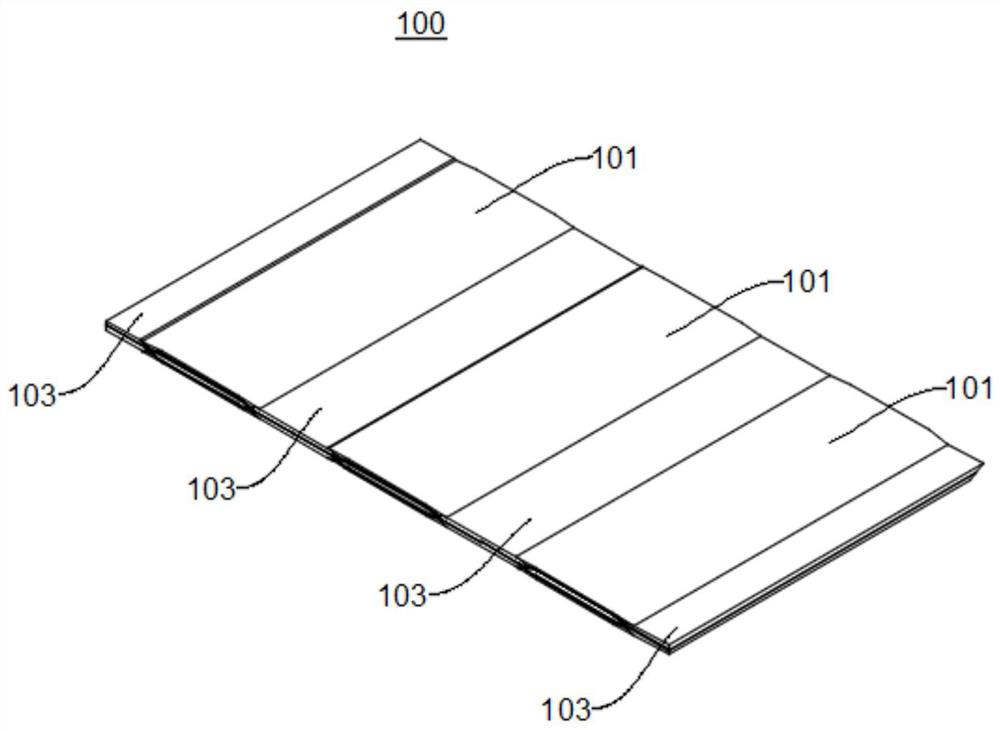

[0041] Please refer to Figure 1 to Figure 4 , this embodiment provides a composite base material 100, which can be used to prepare positive and negative pole pieces of a battery, so as to increase the weight energy density of the battery and improve the conductive contact performance between the metal layer and the active material coating of the pole piece. Further improve the safety performance of lithium-ion batteries. Moreover, the composite base material 100 is easy to weld and has strong adhesive force, which is beneficial to prevent the problem of the metal layer falling off during the cycle of the battery using the composite current collector.

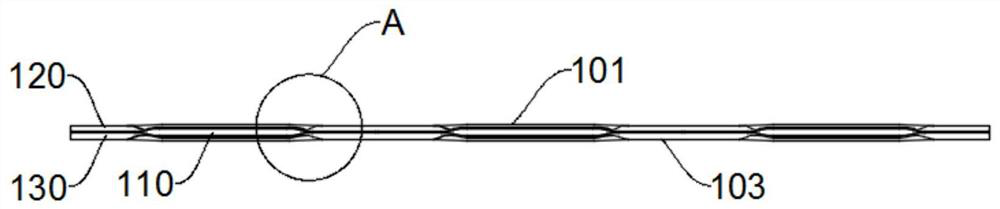

[0042]In this embodiment, the composite substrate 100 includes an insulating base 110, a first metal layer 120, and a second metal layer 130, and the insulating base 110 includes a first surface (not marked in the figure) and a second surface (not marked in the figure) that are oppositely arranged. , the first metal layer 120 ...

no. 2 example

[0050] Please refer to Figure 5 , the embodiment of the present invention provides a method for preparing a composite substrate 100, which is used to prepare the above-mentioned composite substrate 100. The method for preparing the composite substrate 100 includes:

[0051] S100 : providing an insulating substrate 110 , a first metal layer 120 and a second metal layer 130 . A first metal layer 120 and a second metal layer 130 are disposed on opposite first and second surfaces of the insulating substrate 110, respectively. Wherein, the widths of the first metal layer 120 and the second metal layer 130 are respectively greater than the width of the insulating base 110, and the part of the first metal layer 120 exceeding the width of the insulating base 110 is bonded with the part of the second metal layer 130 exceeding the width of the insulating base 110 And electrically conductive. The area of the first metal layer 120 and the second metal layer 130 corresponding to the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com