Low-fault physical heat dissipation buried transformer substation

A fault physics, substation technology, applied in the field of substations, can solve the problems of heat dissipation, high maintenance cost, energy loss, etc., to achieve good heat dissipation effect and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

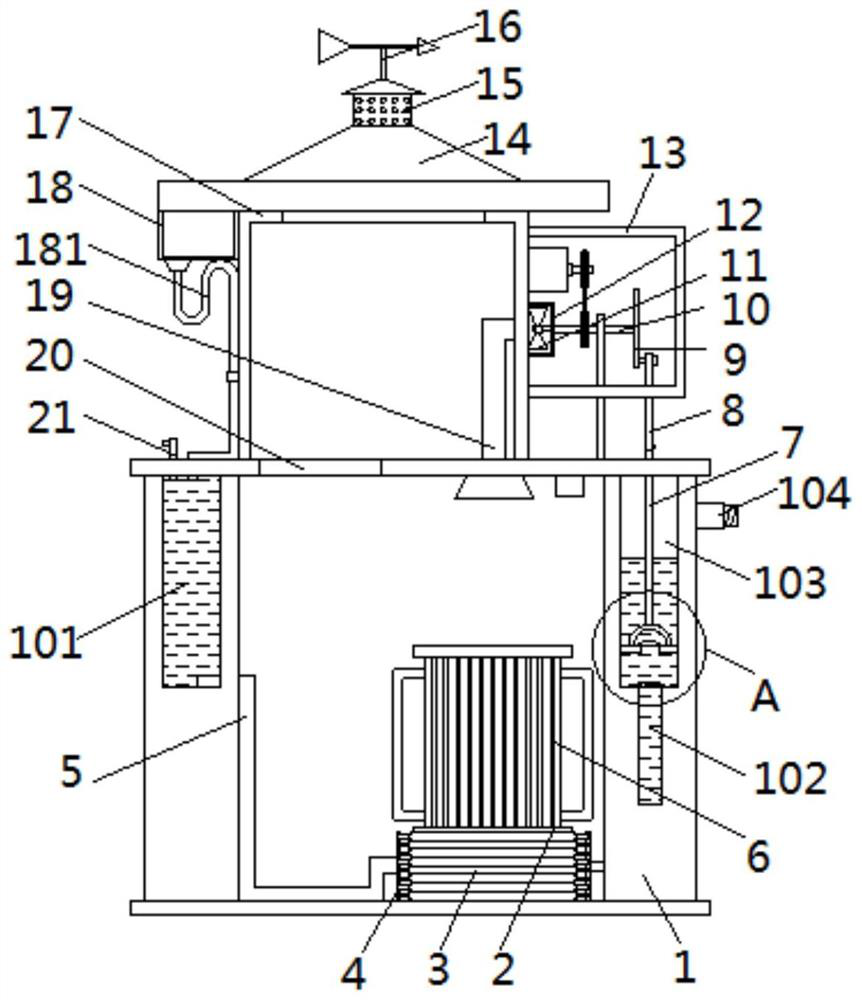

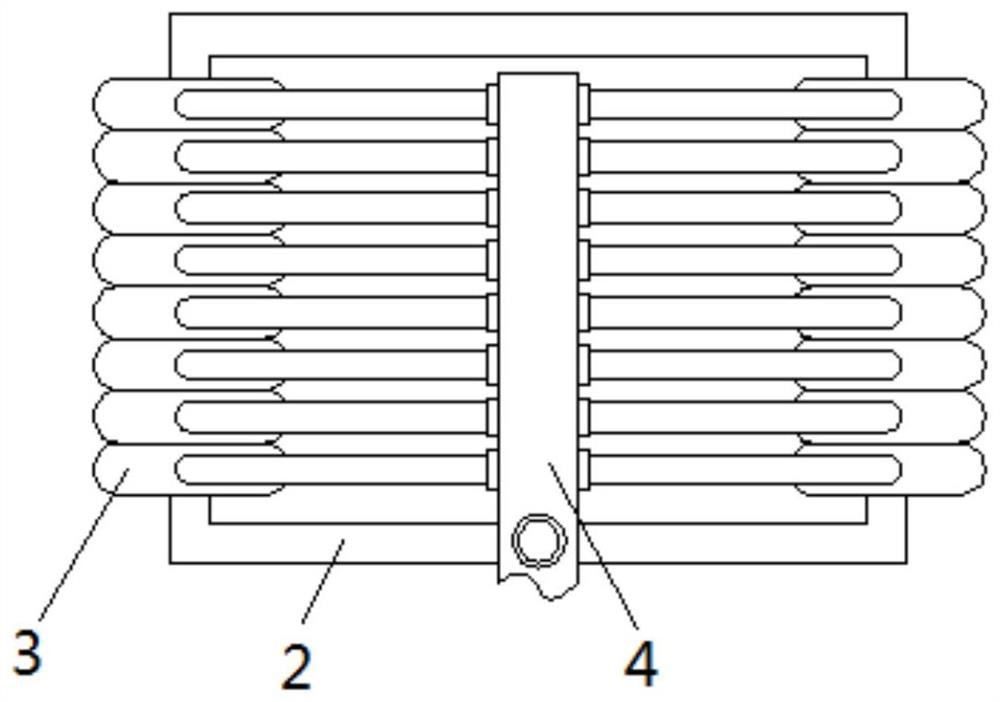

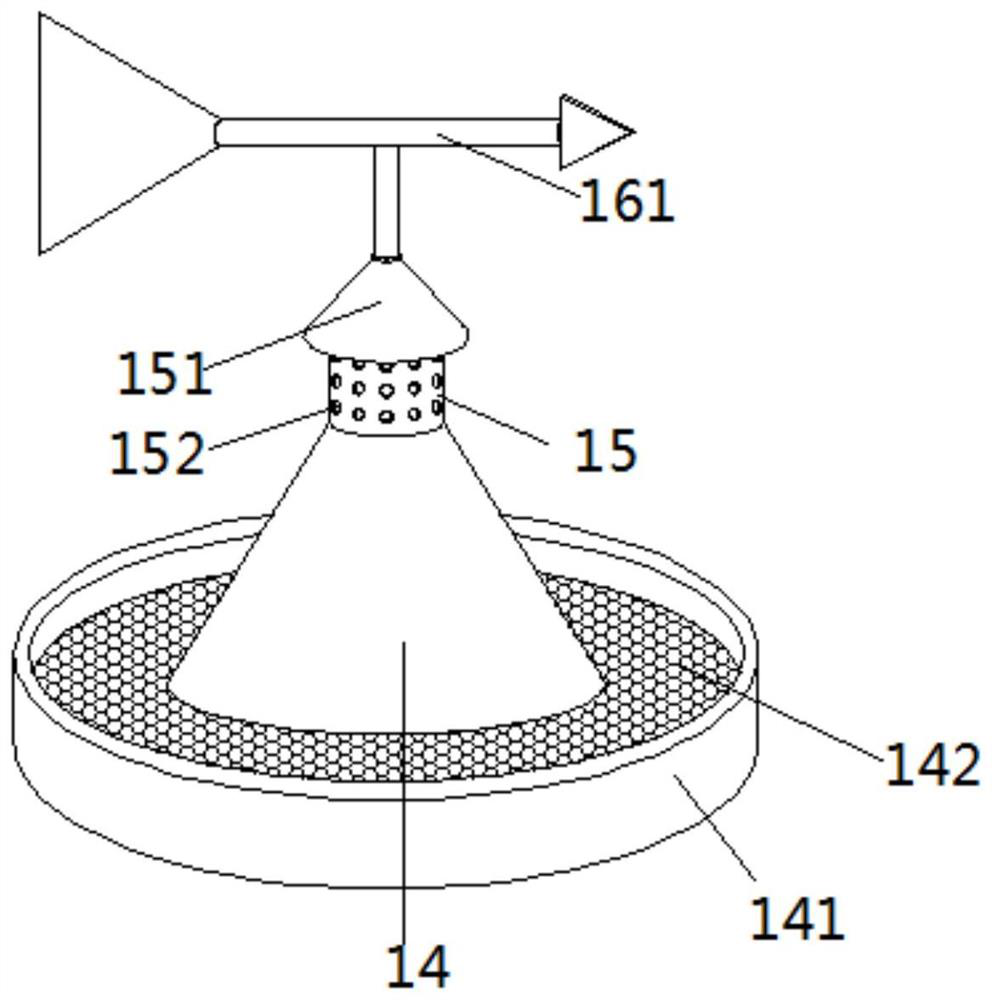

[0030] as attached figure 1 to attach Figure 7 Shown: an underground substation with low failure and physical heat dissipation, including box transformer 1, substation equipment 6, cooling box 17, and through slot 20. There is a through slot 20 on the center side of the top of box transformer 1, and the top of box transformer 1 is located at The upper end of the channel 20 is fixedly connected with a heat dissipation box 17, the top of the heat dissipation box 17 is fixedly connected with a rain-shielding water collection cover 14, and the top of the rain-shielding water collection cover 14 is fixedly connected with an air inlet tube 15, and the center of the top of the air inlet tube 15 is movably connected with a wind direction Device 16, the inside of cooling box 17 is fixedly connected with exhaust pipe 19 on the side away from No. 1 water chamber 101, the bottom of exhaust pipe 19 extends to the inside of box transformer 1 and is fixedly connected with an air inlet cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com