Assembled cable wall penetrating device

An assembled, cable technology, applied in cable laying equipment, electrical components and other directions, can solve the problems of substation firewall function loss, fire and flame retardant baffle damage, cable damage and other problems, achieve simple structure, avoid large area damage, eliminate damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

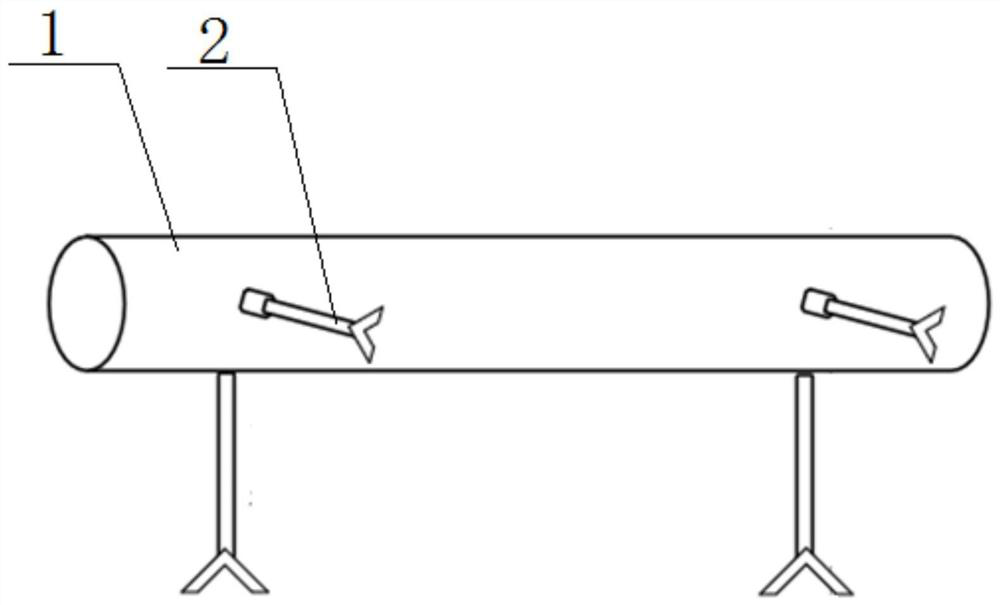

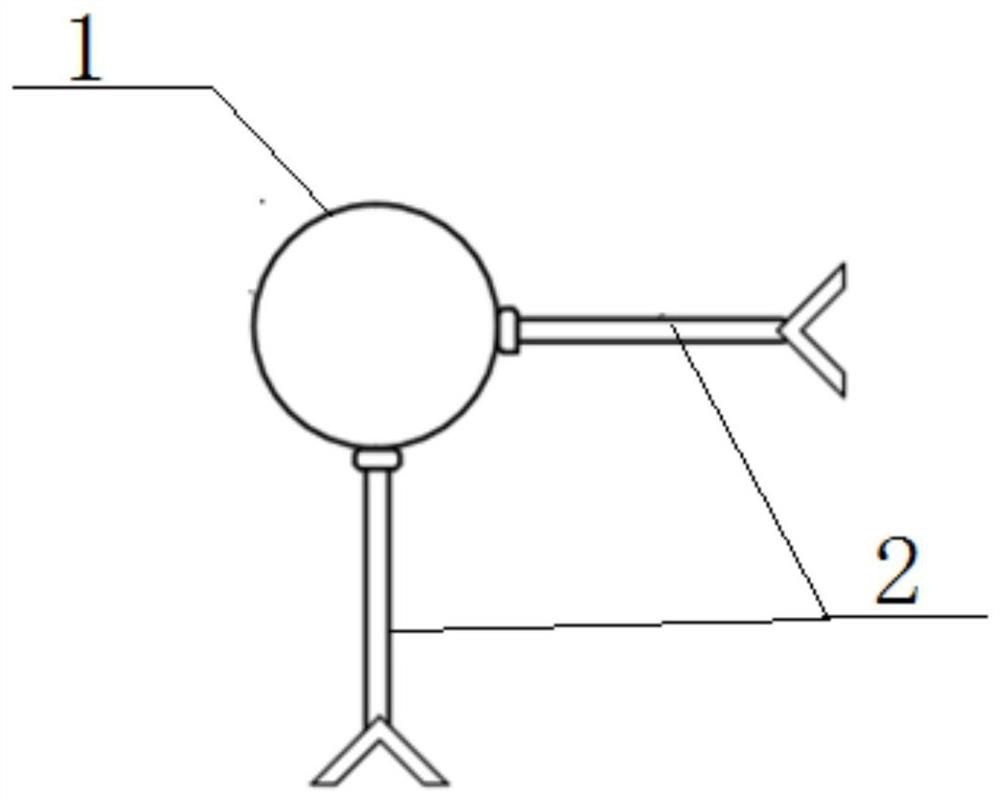

[0035] Such as figure 1 and figure 2 As shown, an assembled cable wall penetrator is used for a cable trench firewall, including a loose-leaf tube body 1, and several telescopic tripods 2 are divided into two groups, which are arranged in a straight line along the side wall of the loose-leaf tube body 1 and installed evenly. The planes arranged by the telescopic tripods 2 are perpendicular to each other; each set of telescopic tripods 2 contains at least two telescopic tripods 2;

[0036] The telescopic tripod 2 is detachably mounted on the loose-leaf tube body 1;

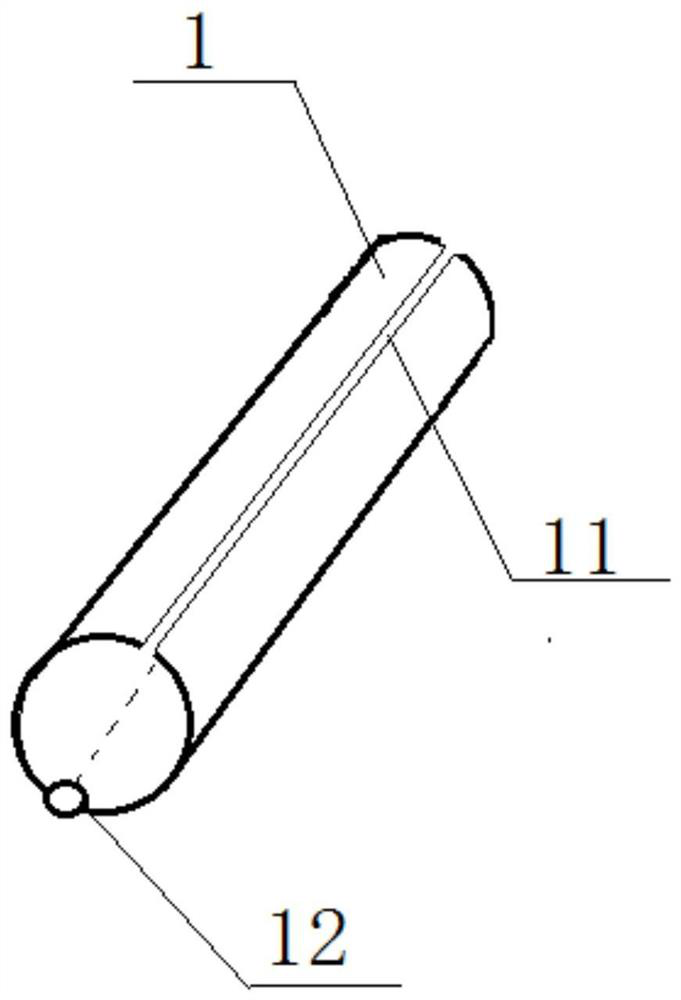

[0037] The loose-leaf tube body 1 indicates that the side wall of the tube body can be opened and closed, such as image 3 As shown, the opening 11 of the tube wall of the loose-leaf tube body 1 and the loose-leaf shaft 12 corresponding to the opening 11, when the wall penetrator is working, the opening 11 is fastened by a buckle.

[0038] The loose-leaf tube body 1 is arranged in a straight line along the side...

Embodiment 2

[0048] Such as Figure 4 As shown, for the assembled cable wall penetrator designed according to the present invention, four telescopic tripods are selected, two telescopic tripods are installed and supported on the bottom surface of the loose-leaf tube body, and the remaining two telescopic tripods are installed and supported on the loose-leaf tube. On the right side of the body, the planes arranged by two sets of telescopic tripods 2 are perpendicular to each other; two sets of corrugations are designed on the tube body, each set of corrugations includes a raised part 3 and a concave part 4, and the corrugated concave part 4 is laid towards the cable Direction, the cable 5 is laid from the concave part 4, and the corrugated concave part 4 has a buffering protection effect on the cable bending.

[0049]During use, first select the tube body suitable for the current cable specification, assemble the loose-leaf tube body into a complete cable tube, pass through the firewall wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com