A potato agricultural product processing device

A technology for processing agricultural products and potatoes, which is applied in the field of processing devices for potato agricultural products. It can solve the problems of complex structure, damage, and large size, and achieve the effects of reducing the cleaning process, speeding up the peeling process, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

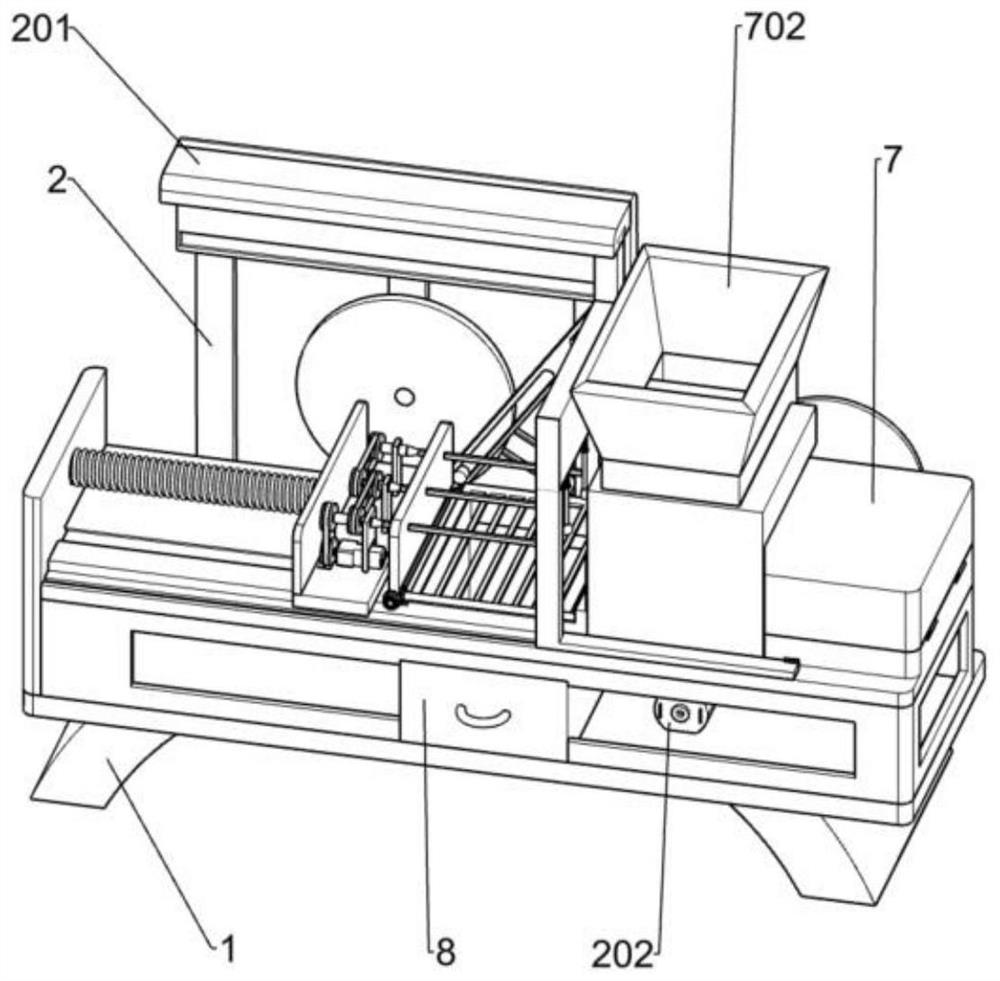

[0031] A potato agricultural product processing device, such as Figure 1-6Shown, comprise frame 1, the first support plate 2, the first slide frame 201 and feed box 8, three first support plates 2 are fixedly installed on the upper rear side of frame 1, the first slide frame 201 and three The upper end of the first support plate 2 is fixedly connected, and the material box 8 is fixedly installed in the middle position of the frame 1, and is characterized in that: it also includes: a power mechanism, a rotating mechanism and a peeling mechanism, and the power mechanism is fixedly installed on the frame 1 The rear part, the rotating mechanism is fixedly installed in the upper middle position of the frame 1, and the peeling mechanism is slidably installed in the upper middle position of the frame 1 on the right side, the peeling mechanism is connected with the power mechanism, and the peeling mechanism is connected with the rotating mechanism.

[0032] Working principle: When pr...

Embodiment 2

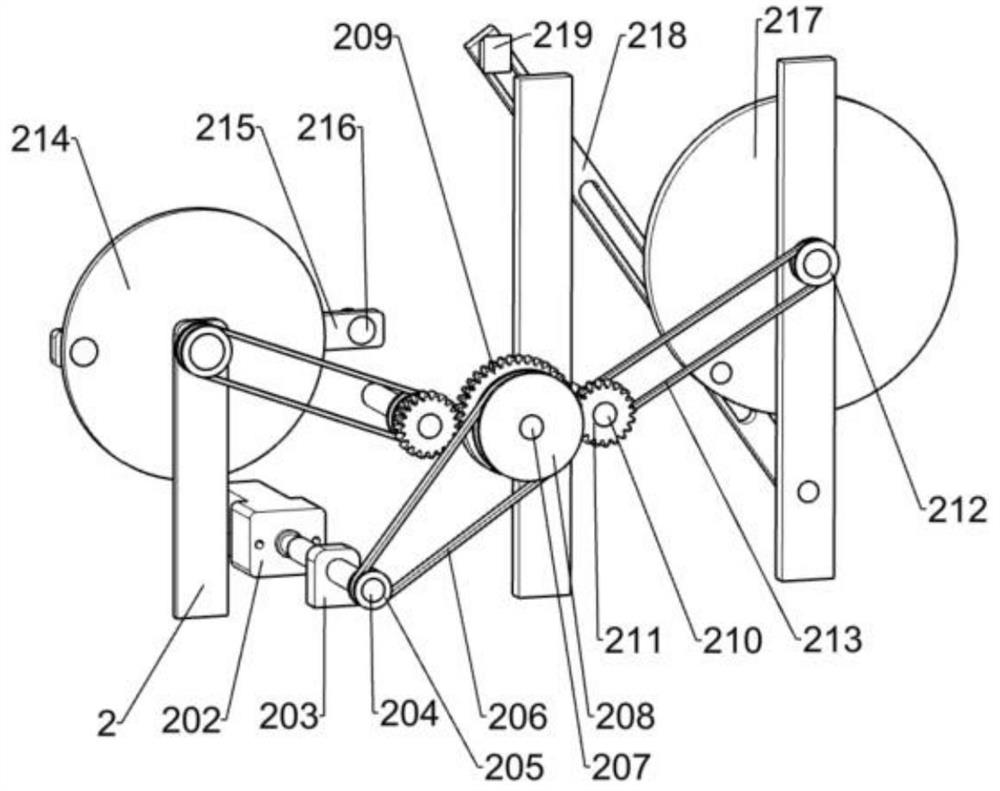

[0034] On the basis of Example 1, such as figure 2 As shown, the power mechanism includes a first motor 202, a support block 203, a first shaft 204, a first pulley 205, a first belt 206, a second shaft 207, a second pulley 208, a missing tooth gear 209, The third shaft rod 210, the first spur gear 211, the third pulley 212, the second belt 213 and the reciprocating mechanism, the first motor 202 is fixedly installed on the right rear side of the middle part of the frame 1, and the support block 203 is fixedly installed on On the right rear side of the middle part of the frame 1, the front end of the first shaft rod 204 is fixedly installed on the output shaft of the first motor 202, the first shaft rod 204 is rotationally connected with the support block 203, and the first pulley 205 is fixedly installed on the The rear end of the first axle bar 204, the front end of the second axle bar 207 is rotatably installed on the rear upper side of the frame 1, the second pulley 208 is...

Embodiment 3

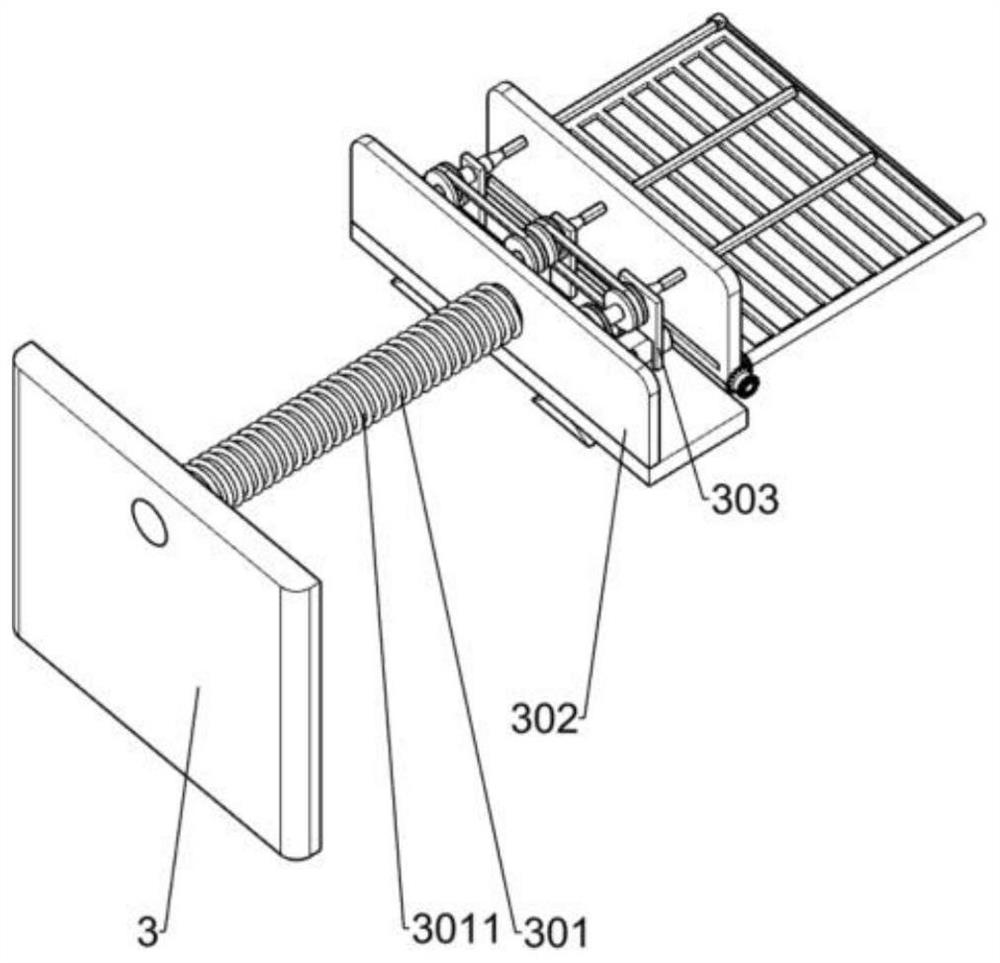

[0043] On the basis of Example 2, such as Figure 7 As shown, a turning mechanism is also included, and the turning mechanism includes an L-shaped plate 5, a gear bar 501, a fifth shaft 502, a second spur gear 503, a bevel gear 504, a sixth shaft 505 and a bracket 506, and the L-shaped plate The left side of the rear portion of 5 is fixedly connected with the slide frame 4, the lower side of the L-shaped plate 5 is slidably connected with the frame 1, the gear bar 501 is fixedly installed on the upper right side of the L-shaped plate 5, and the fifth shaft rod 502 is rotatably installed on the On the lower side of the fixed plate 312, the second spur gear 503 is fixedly installed on the front end of the fifth shaft 502, a bevel gear 504 is fixedly installed on the front side of the fifth shaft 502, and the bracket 506 is installed in the slot opened on the frame 1 Inside, a sixth shaft 505 is fixedly installed on the front side of the bracket 506, the sixth shaft 505 is rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com