Civil engineering stone sand screening device

A screening device and stone sand technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of affecting the screening effect, stone sand agglomeration due to moisture, etc., and achieve the goal of ensuring the screening effect, flexible and convenient use, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

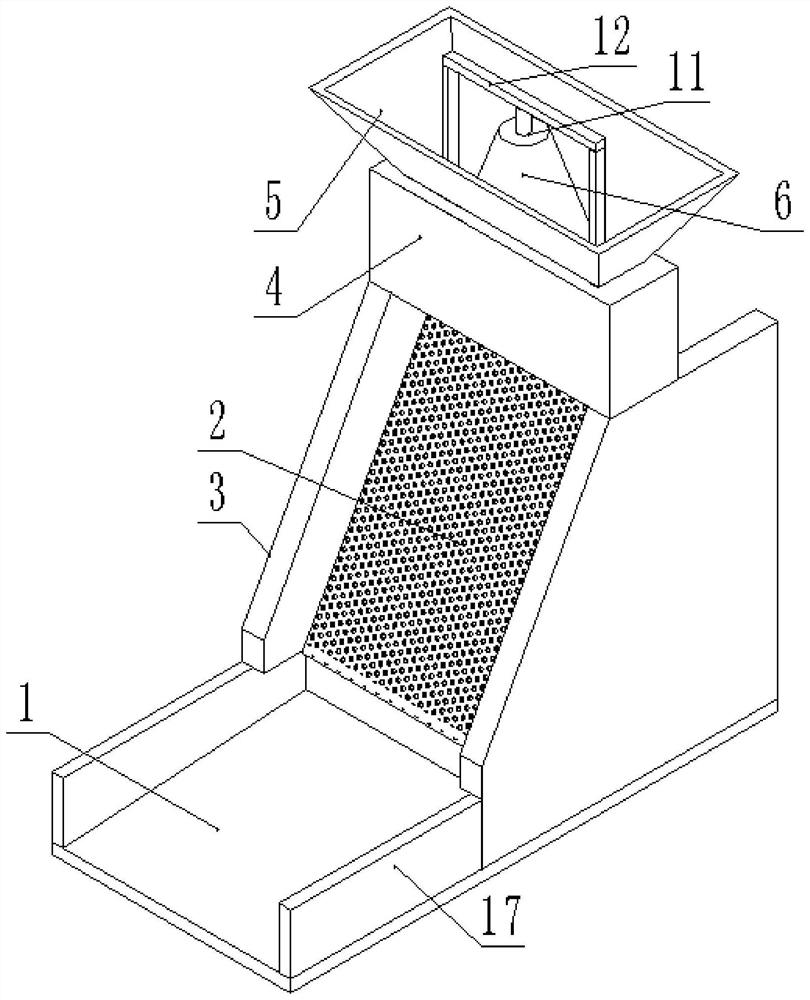

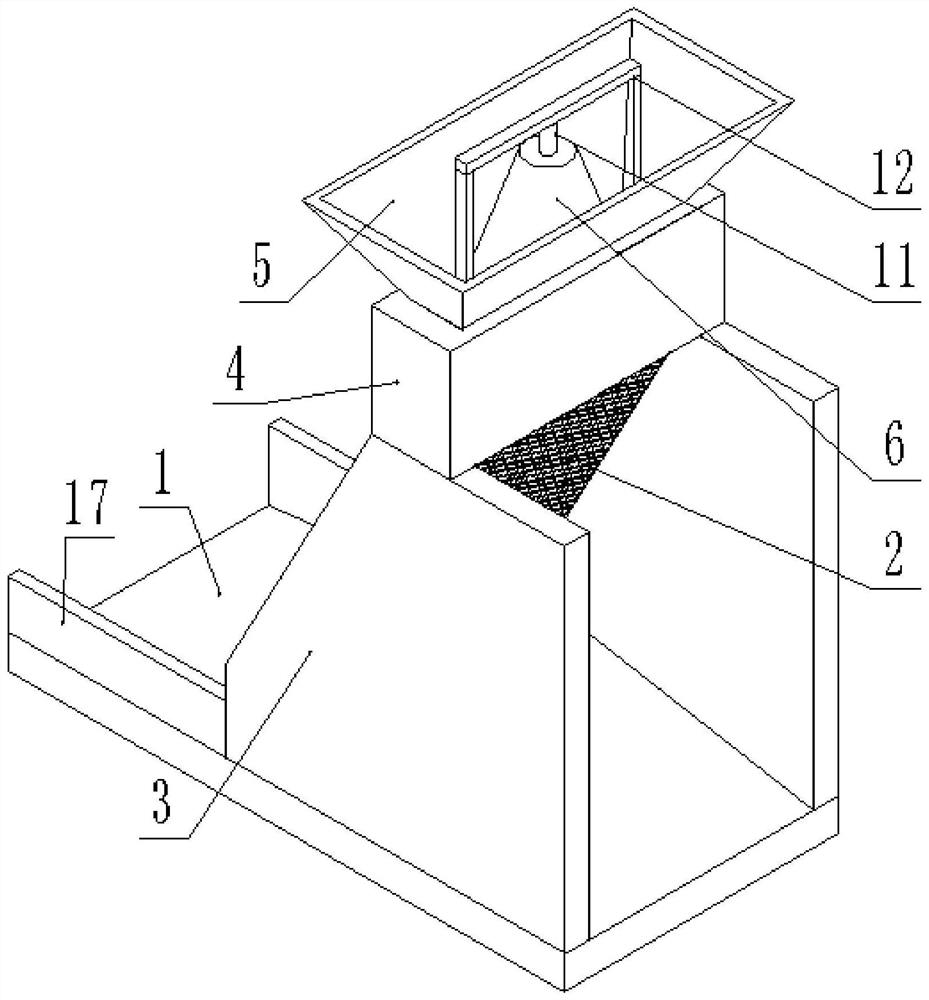

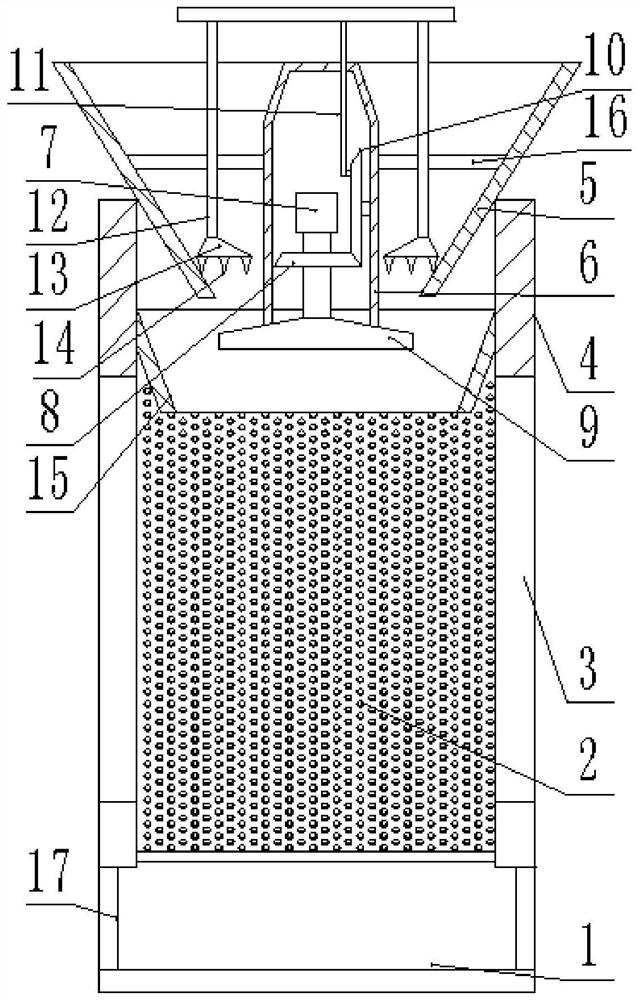

[0032] A civil stone sand screening device, such as figure 1 and figure 2 As shown, it includes a base 1 and a sand net 2, the base 1 is provided with a mounting plate 3, and an inclined sand net 2 is arranged between the mounting plates 3; the outside of the base 1 is provided with a fence 17, and one side of the base 1 A gap is provided, and the base 1 is respectively provided with slopes on both sides of the sand net 2 .

[0033] After the sand net 2 screens the stones and sand, the stones and sand are separated and fall to the base 1 respectively and leave along the slope on the base to prevent accumulation at the connection between the sand net 2 and the base 1 and affect the subsequent screening effect; And the mounting plate 3 and the fence 17 can limit the scope of falling stones and sand, prevent the stones and sand from being scattered randomly after screening and cause unnecessary cleaning work.

[0034] Such as figure 1 and image 3 As shown, the upper side of...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 4 As shown, the inside of the mounting plate 3 is respectively provided with a cylinder 18 with a notch, and the cylinder 18 is provided with a rotating shaft 19 on which a sand net 2 passing through the gap is installed, and the sand net 2 is wound on the rotating shaft 19 . The sand net 2 is an orderly combination of multiple sand nets 2 with different specifications. By rotating the rotating shaft 19, the sand net 2 is wound on its outside, so as to change the use specifications of the sand net 2 and meet more usage scenarios.

[0042] Such as Figure 4 As shown, one end of the rotating shaft 19 is provided with a ratchet 21 and a ratchet 22, and one end of the ratchet 22 is obliquely installed with a resettable knocking rod 23, and the knocking rod 23 is positioned at one side of the sand net 2; , the rotating shaft 19 drives the ratchet 21 to rotate all the time, and the ratchet 21 rotates so that the ratchet 22 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com