Automatic continuous welding molecular diffusion welding equipment

A molecular diffusion and equipment technology, applied in welding equipment, non-electric welding equipment, shearing machine equipment, etc., can solve problems such as low work efficiency and quality cannot be guaranteed, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

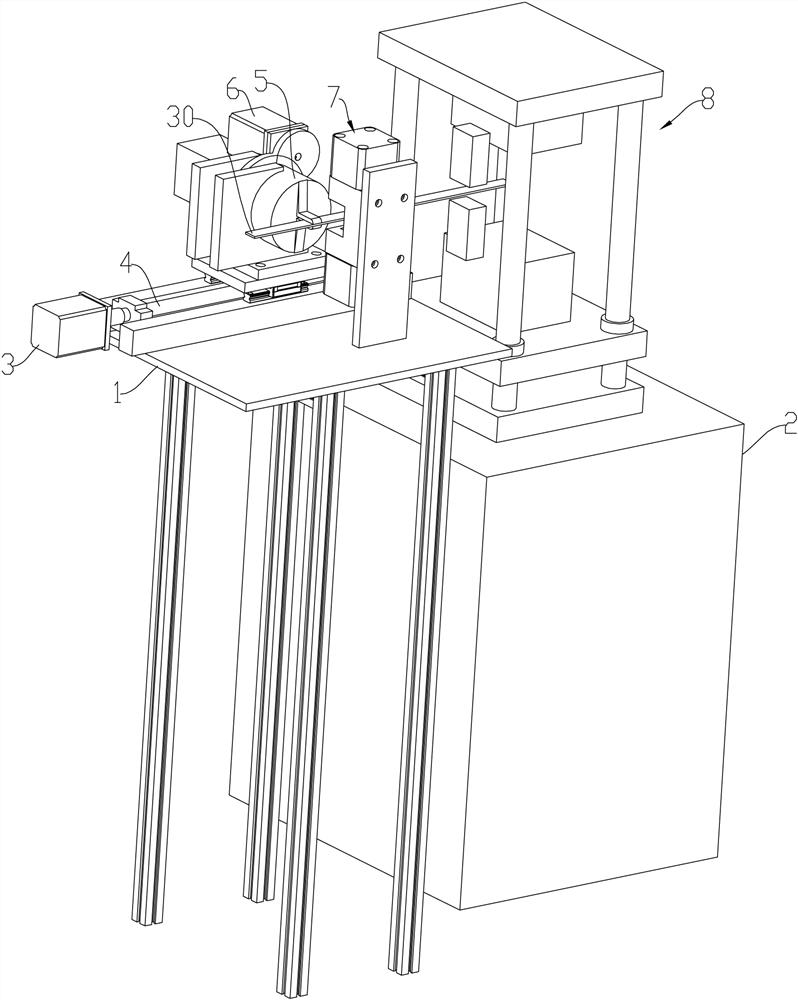

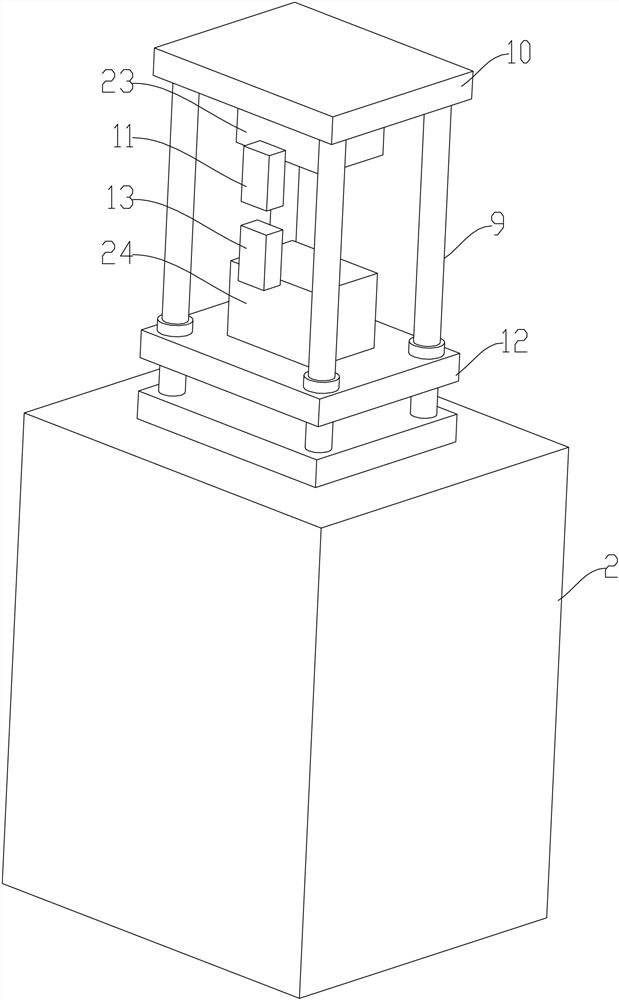

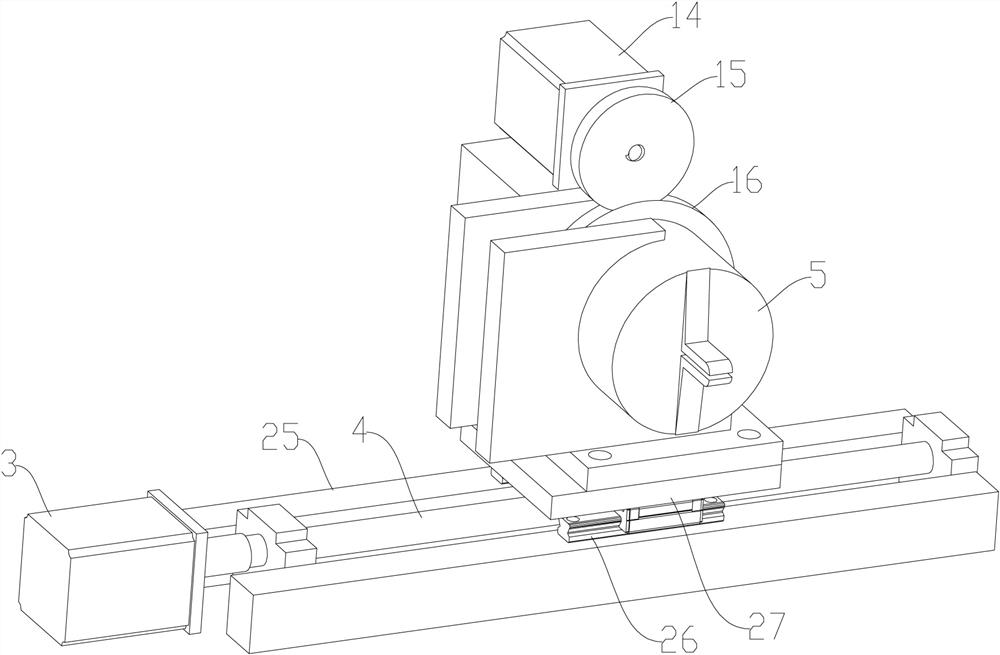

[0020] Such as Figure 1 to Figure 5 As shown, the automatic continuous welding molecular diffusion welding equipment of the present invention includes a work surface 1, a four-column hydraulic machine box 2 arranged next to the work surface 1, a mobile stepper motor 3 arranged on the work surface 1, and The transmission shaft 4 connected to the moving stepper motor 3 , the clamp 5 connected to the transmission shaft 4 and the rotating mechanism 6 that drives the clamp 5 to transport. A cutting mechanism 7 is provided in front of the fixture 5 , and a welding mechanism 8 is provided on the four-column hydraulic machine box 2 . The transmission shaft 4 adopts a screw mandrel, and its rotation can drive the left and right movement of the clamp 5 . The clamp 5 is used to clamp the copper strip 30 . The delivery of the copper strip 30 is delivered by a feeding mechanism arranged on one side of the four-column hydraulic press box body 2 . The feeding mechanism is a prior art, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com