Method for hollow glass production and processing

A processing method and glass technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of broken glass, the production and processing method of insulating glass cannot perform auxiliary storage operations, and reduce the flexibility of insulating glass, etc. , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

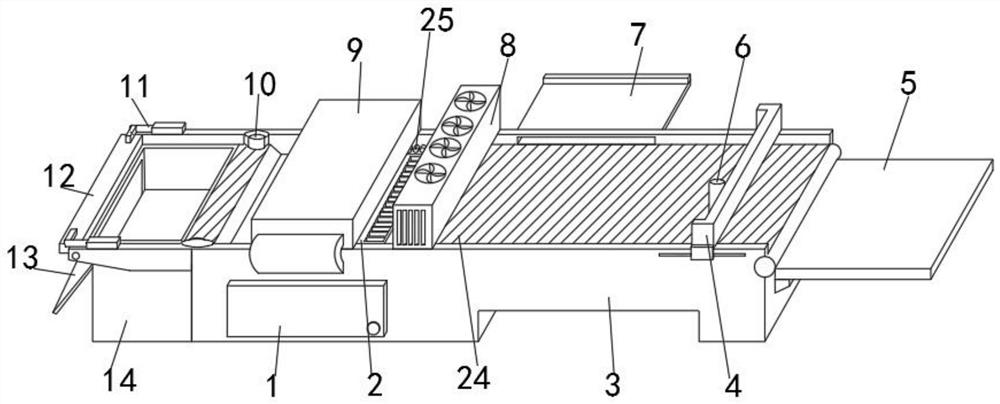

[0028] Such as Figure 1-4 Shown, a kind of production and processing method of insulating glass, the concrete steps of this method comprise:

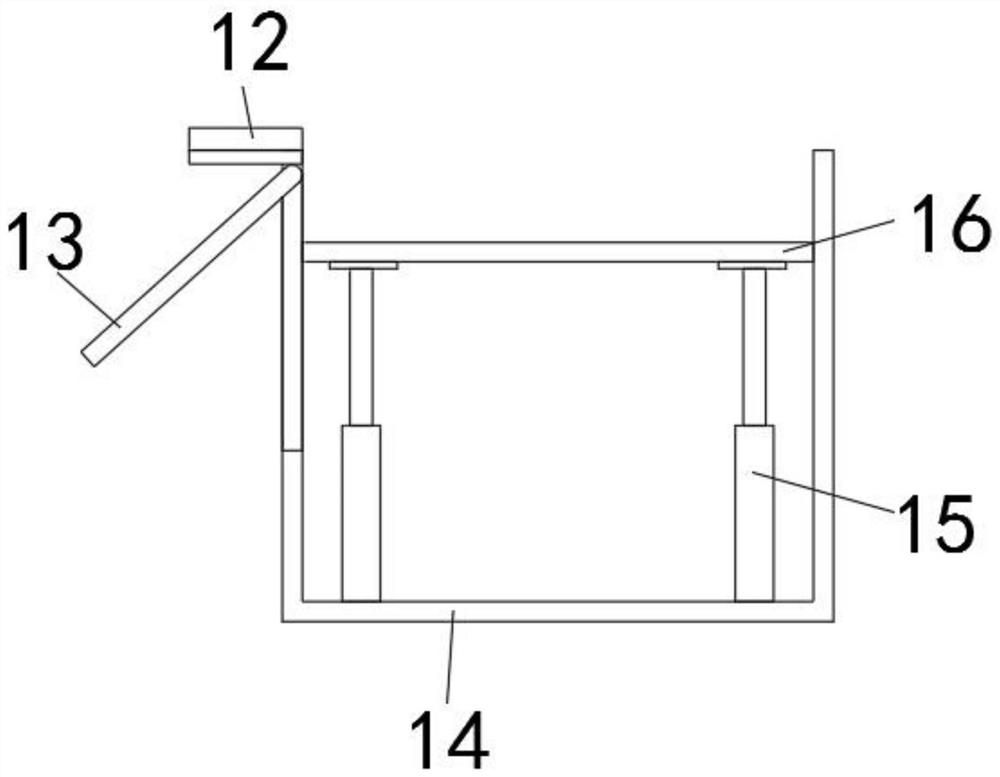

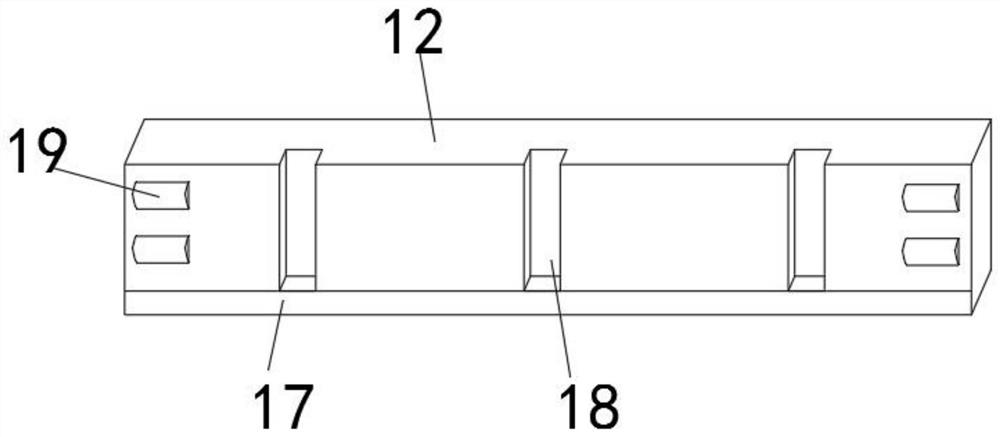

[0029] Step 1, open the side screw cover plate 13 of the box base 14, stack the glass material on the lifting top plate 16 of the box base 14, use the second hydraulic rod 15 to push the lifting top plate 16, so that the lifting top plate 16 drives the glass material Move, so that the glass material is ejected from the box base 14, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com