Crystallization frit, jade light-transmitting brick and preparation method of jade light-transmitting brick

A light-transmitting brick and crystallization technology, which is applied in the preparation of jade-quality light-transmitting bricks and jade-quality light-transmitting bricks, and in the field of crystallization frit, which can solve problems such as dry holes, difficult production, and difficult control of brick shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

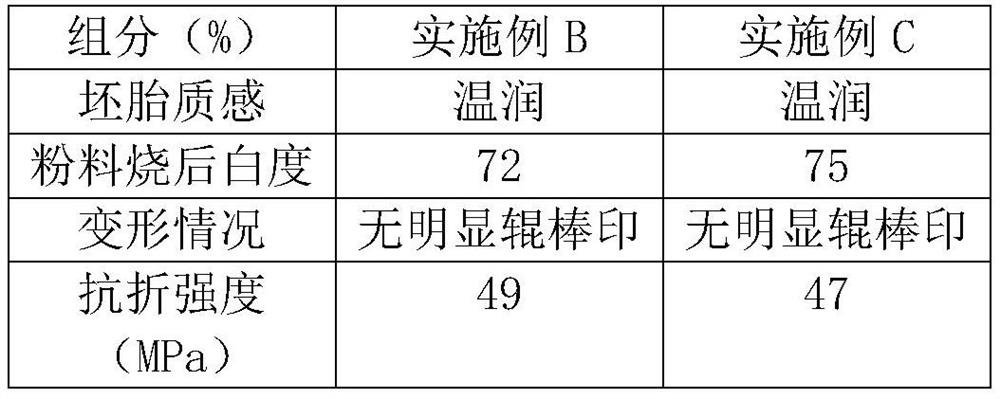

Examples

preparation example Construction

[0039] A preparation method of jade translucent bricks, comprising the following steps:

[0040] Step (1): According to the above-mentioned raw material ingredients of crystallization frit, mix uniformly, melt at 1500-1600° C., and obtain crystallization frit after water quenching;

[0041] Step (2): According to parts by weight, weigh 3-15 parts of ultra-white kaolin, 10-20 parts of ball clay, 1-5 parts of high-white bentonite, 10-30 parts of ultra-white quartz powder, 10-20 parts 20 parts of high white potassium feldspar, 1 to 5 parts of wollastonite, 1 to 5 parts of calcined talc and 25 to 40 parts of the crystallization frit prepared in the step (1); mix uniformly after the ingredients, and prepare get mixed billets;

[0042] Step (3): ball milling the mixed blank to obtain a translucent blank, cloth, and pressing the translucent blank;

[0043] Among them, the ball milling process parameters are 32-38% water content, 1.63-1.71 specific gravity, 35-80 seconds flow rate, ...

Embodiment A

[0055] The raw materials used in the frit include: ultra-white washed potassium feldspar, ultra-white sodium feldspar, quartz powder, alumina, calcite, calcined talc, soda ash, barium carbonate, calcium fluoride, calcium phosphate and spodumene, after mixing, The crystallized frit after water quenching was melted at 1530°C, and the chemical composition of the crystallized frit is shown in Table 1;

[0056] The green body of the jade translucent brick uses 5 parts of ultra-white kaolin, 13 parts of ball clay, 4 parts of high-white bentonite, 28 parts of ultra-white quartz powder, and 17 parts of high-white Potassium feldspar, 2 parts of wollastonite, 1 part of calcined talc and 30 parts of crystallization frit.

Embodiment A1

[0058] Through the processes of batching, ball milling, iron removal, powder spraying, aging, etc., the translucent billet is obtained. The parameters of the ball milling process are 35% moisture, 1.65 specific gravity, 60 seconds flow rate, and 0.6 residue on 250-mesh sieve. For the black blank, use ball-milled glaze slurry 100 (dry weight), add 0.17% of the total mass of dark black material, 0.3% dark gray material, and spray powder to obtain black powder; for light gray blank, use ball milling Good glaze slurry 100 (dry weight), add 0.018% dark black material, 0.125% dark gray material, 0.018 orange yellow material, and spray powder to get light gray powder; for the yellow blank, it is ball milled Glaze slurry 100 (dry weight), add 0.01% dark black material, 0.03% dark gray material, 0.3% orange yellow material, spray powder to get yellow powder;

[0059] Use four kinds of powder materials: transparent white billet, black billet, light gray billet and yellow billet, lay out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com