Water feeding control method and device, washing machine and storage medium

A water inflow control and water inflow technology, which is applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems affecting the user experience of fully automatic washing machine, so as to improve user experience, improve control mode and reduce excessive waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

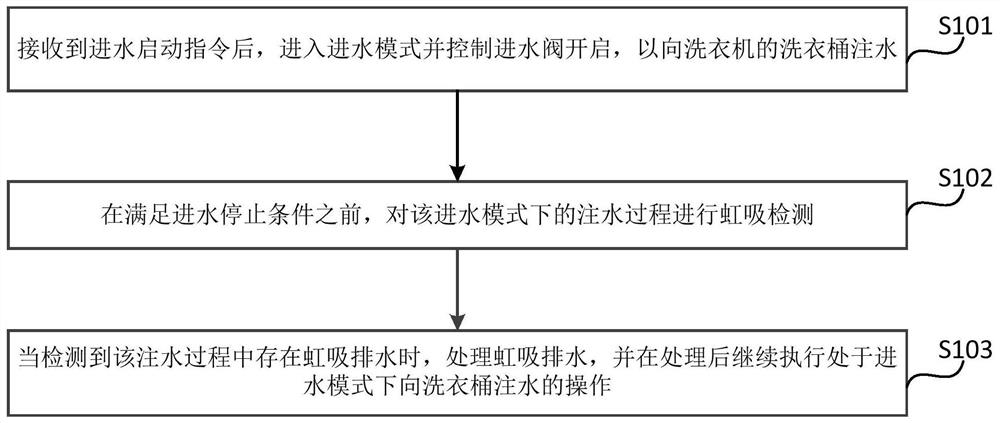

[0065] figure 1 It is a schematic flowchart of a water inflow control method provided in Embodiment 1 of the present application, and the method is suitable for controlling the water inflow process of a fully automatic washing machine. The method can be executed by a washing machine embedded with a control chip, and the water inflow control method can be written in the control chip as the water inflow processing logic.

[0066] Such as figure 1 As shown, a water inflow control method provided in Embodiment 1 specifically includes the following steps:

[0067] S101. After receiving the water inlet start instruction, enter the water inlet mode and control the water inlet valve to open, so as to fill the washing bucket of the washing machine with water.

[0068] It can be known that for a fully automatic washing machine, after it is powered on and the laundry program is selected by the user to start the work, the water inflow start command can be generated after the water inflo...

Embodiment 2

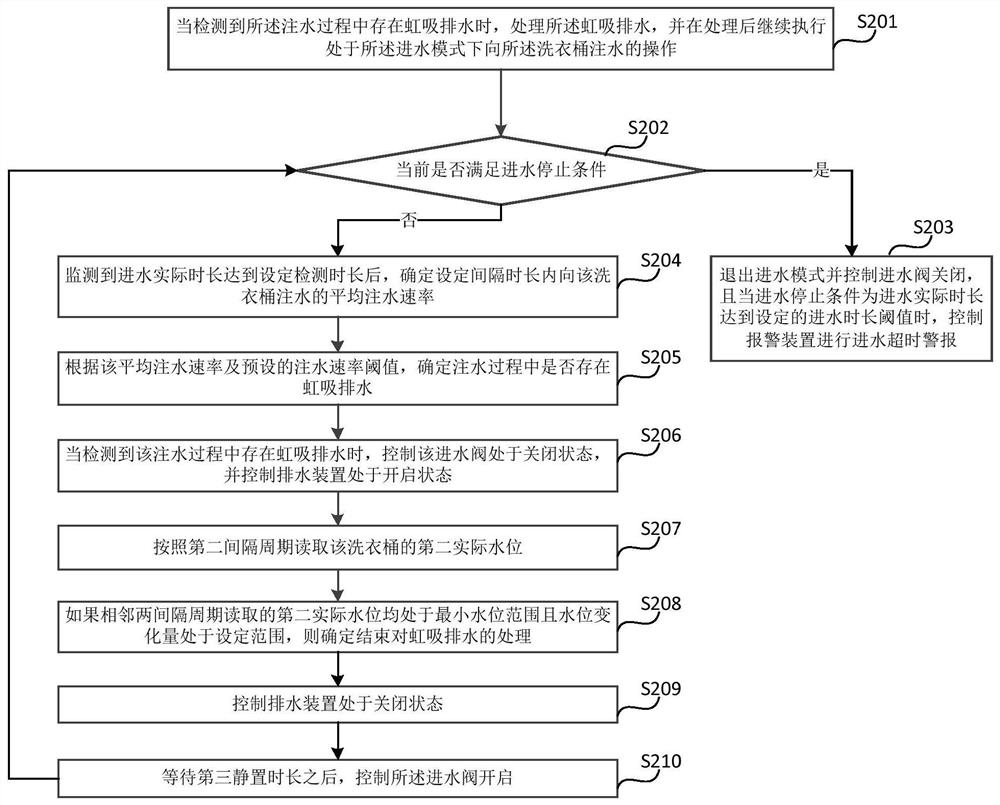

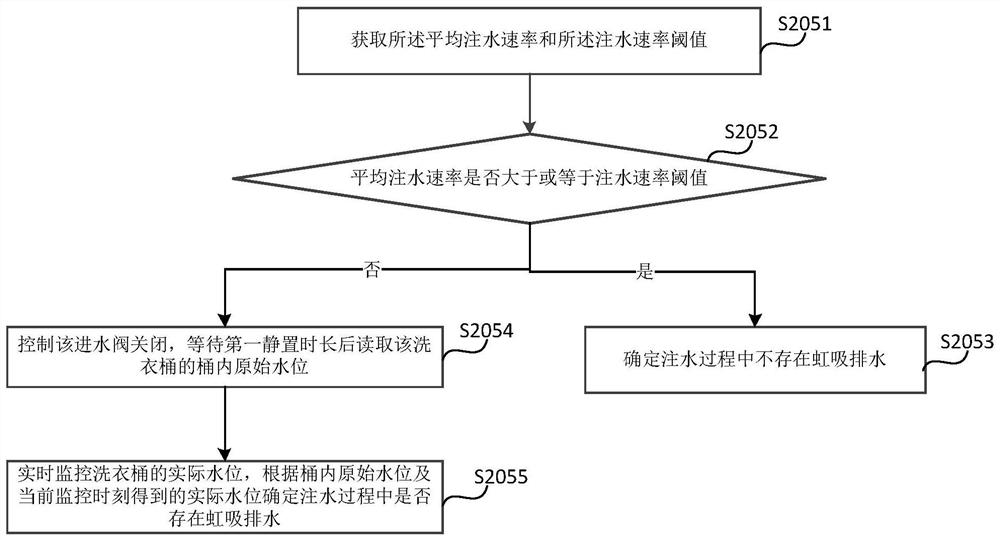

[0086] figure 2 It is a schematic flow chart of a water inflow control method provided in Embodiment 2 of the present application. This embodiment is based on the above embodiments. In this embodiment, the siphon detection of the water injection process under the water inflow mode can be specifically expressed It is: after monitoring that the actual time of water inflow reaches the set detection time, determine the average water injection rate of water injection into the washing bucket within the set interval time, and the actual time of water inflow is the actual cumulative time of water filling into the washing bucket; according to the average water injection The rate and the preset water injection rate threshold determine whether there is siphon drainage during the water injection process.

[0087] At the same time, in this embodiment, the processing steps of the siphon drainage can also be specifically expressed as: controlling the water inlet valve to be in the closed st...

Embodiment 3

[0199] image 3 It is a structural block diagram of a water inlet control device provided in Embodiment 3 of the present application, and the device is suitable for controlling the water inlet process of a fully automatic washing machine. Specifically, the device can be embedded in the washing machine in the form of a chip. Such as image 3 As shown, the device includes: a water intake execution module 31 , a siphon detection module 32 and a siphon processing module 33 .

[0200] The water inlet execution module 31 is configured to enter the water inlet mode and control the opening of the water inlet valve after receiving the water inlet start command, so as to fill the washing bucket of the washing machine with water;

[0201] A siphon detection module 32, configured to perform siphon detection on the water injection process in the water inflow mode before the water inflow stop condition is met;

[0202] The siphon processing module 33 is configured to process the siphon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com