Spanning type formwork supporting system

A formwork support and leap-forward technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as inconvenient erection and no flat foundation, and achieve cost saving, small cost, and solution big problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

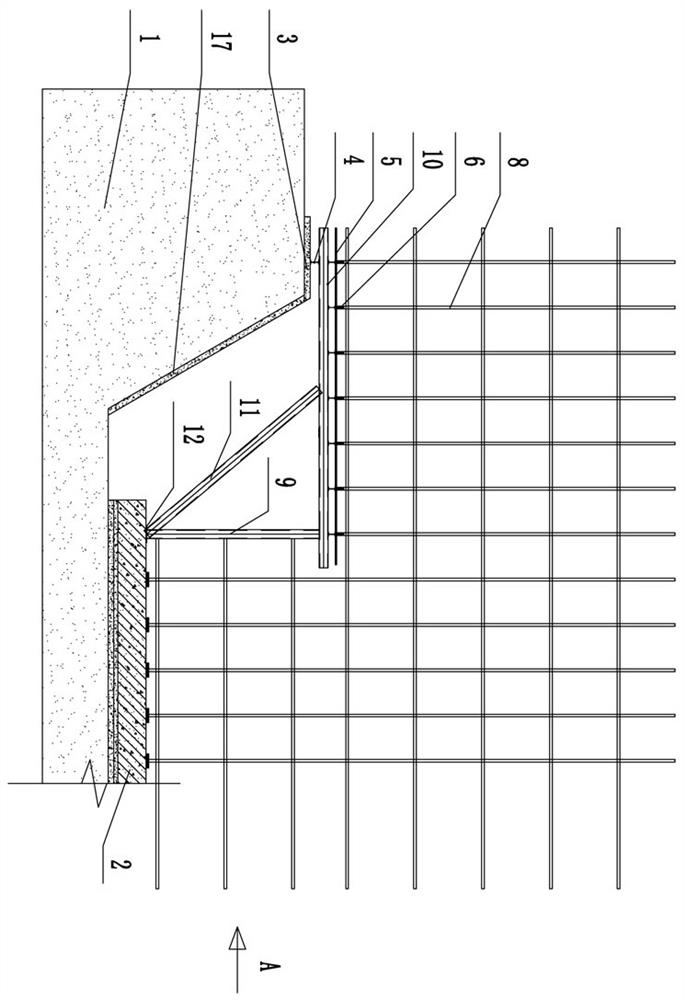

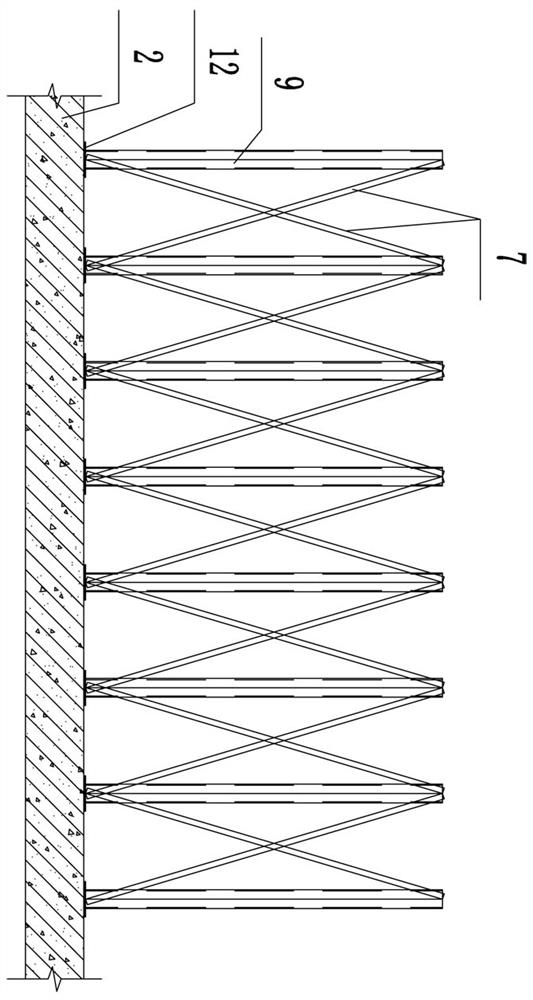

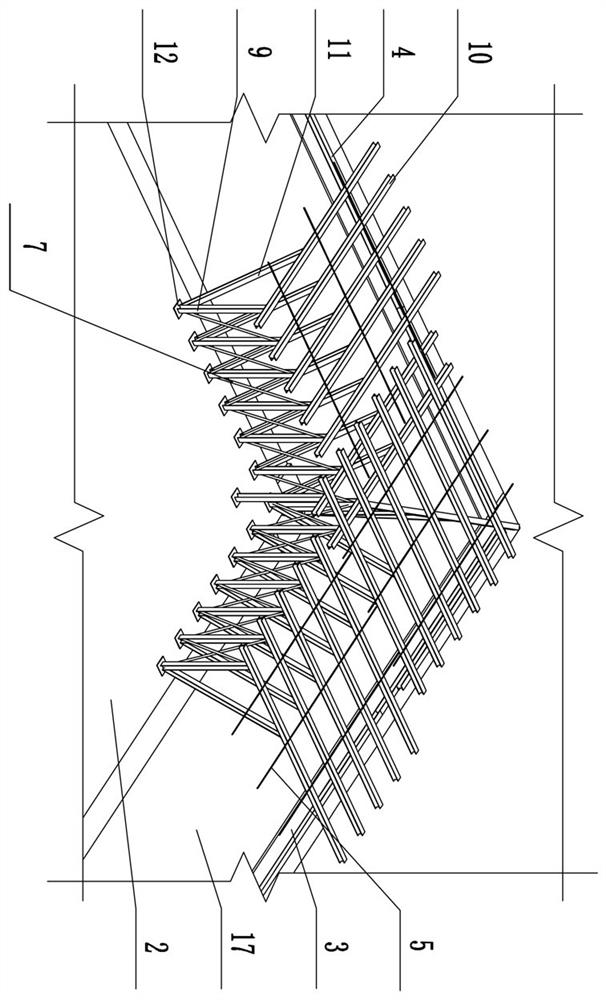

[0031] Such as Figure 1~Figure 8 As shown, a spanning formwork support system includes a foundation pit 1, a raft foundation 2 is laid on the bottom of the foundation pit 1, and the raft foundation 2 is the internal foundation of the main building, that is, one of the supports of the overall I-beam platform. A slope protection 17 is laid on the slope of the foundation pit 1, and the upper end of the slope protection 17 extends to the top surface of the foundation pit 1 to form a slope protection flanging 3;

[0032] The slope of the foundation pit 1 is distributed between the top surface of the foundation pit 1 and the bottom surface of the foundation pit 1, and the slope of the foundation pit 1 is the part that the full support system needs to span; An I-steel platform, the I-steel platform is located above the slope of the foundation pit 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com