Temporary barrier for environmental isolation

A kind of environmental isolation and temporary technology, applied in the direction of using liquid separation agent, filtration separation, separation method, etc., can solve the problems of poor noise reduction effect, affecting the quality of life of residents, affecting the working status of employees, etc., and achieve the effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

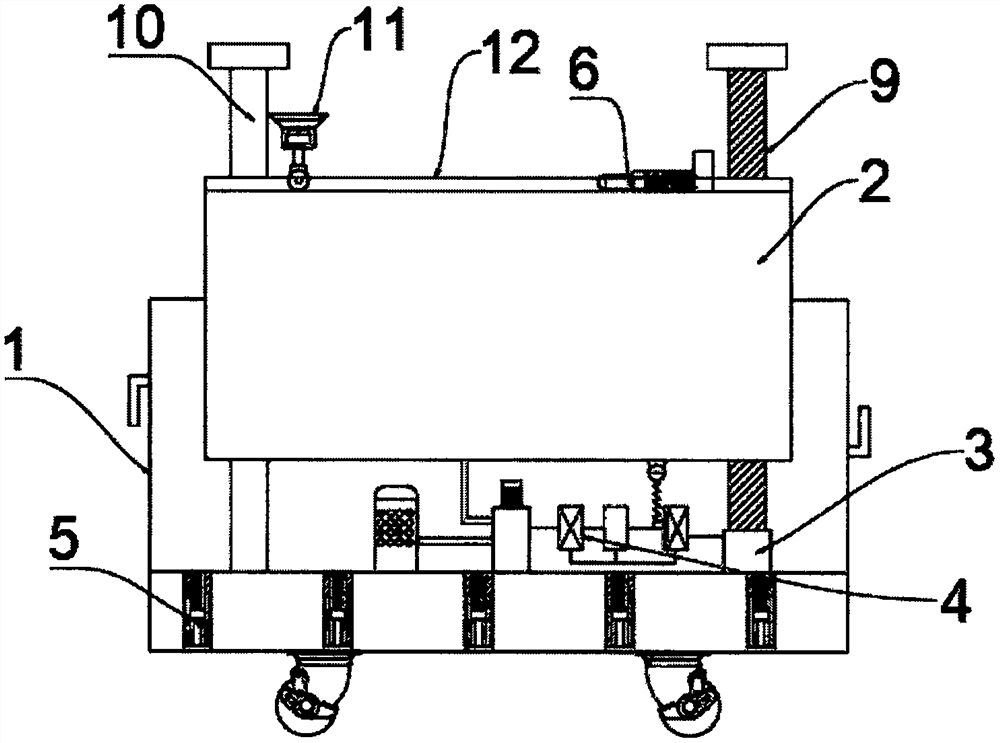

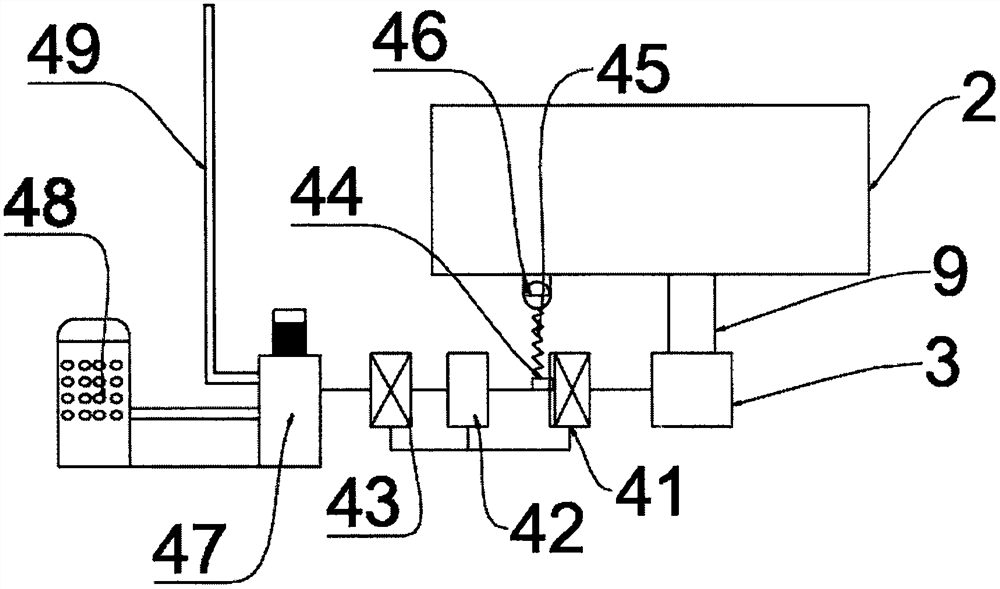

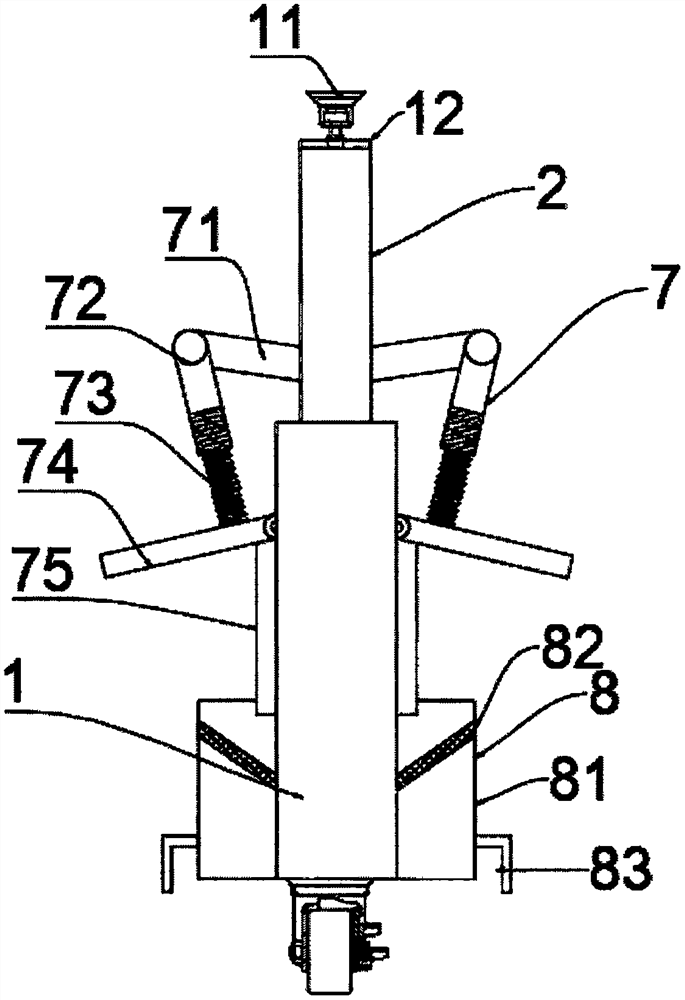

[0029] refer to Figure 1 to Figure 5, a temporary barrier for environmental isolation, including a support side plate 1 and a top plate 2 slidingly installed inside the support side plate 1, a motor 3 is fixedly installed on the inner bottom surface of the support side plate 1, and the output end of the motor 3 is connected with Screw rod 9, and screw rod 9 is threadedly connected with top plate 2, and the bottom of top plate 2 is provided with control device 4, and the side of top plate 2 away from screw rod 9 is slidably connected with the limit bar 10 that is fixedly installed on the inner bottom surface of support side plate 1, and The control device 4 includes an acoustic sensor 41, a power supply 42 and a second acoustic sensor 43 fixedly installed on the inner wall of the support side plate 1, and the power supply 42 is arranged in the middle of the acoustic sensor 41 and the second acoustic sensor 43, and the power supply 42 One side close to the acoustic sensor 41 is...

Embodiment 2

[0037] refer to Figure 6 , a temporary barrier for environmental isolation. Compared with Embodiment 1, the stabilizing device 5 in this embodiment includes a sleeve 51 fixedly installed on the inner top surface of the bottom plate and a slide rail 56 arranged inside the sleeve 51, and the sleeve A stabilizing spring 52 is fixedly installed on the inner top surface of the barrel 51 , a slider 53 slidingly connected with a slide rail 56 is connected below the stabilizing spring 52 , and a bottom bar 55 is connected to the side of the slider 53 away from the stabilizing spring 52 .

[0038] Working principle: When in use, the stability of the device is facilitated by setting the stabilizing device 5 to ensure stable operation during the construction process. When the device is impacted, the sleeve 51 moves down and drives the stabilizing spring 52 to compress, which is convenient for timely Shock offset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com