Tunneling device for coal mining and implementation method thereof

A coal mining and fixing plate technology, which is applied in the direction of earthwork drilling and cutting machinery, etc., can solve the problems of increased screw rod damage, dust raising, unfavorable working environment, etc., so as to reduce the probability of coal falling and suppress dust The effect of raising and speeding up the mining progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

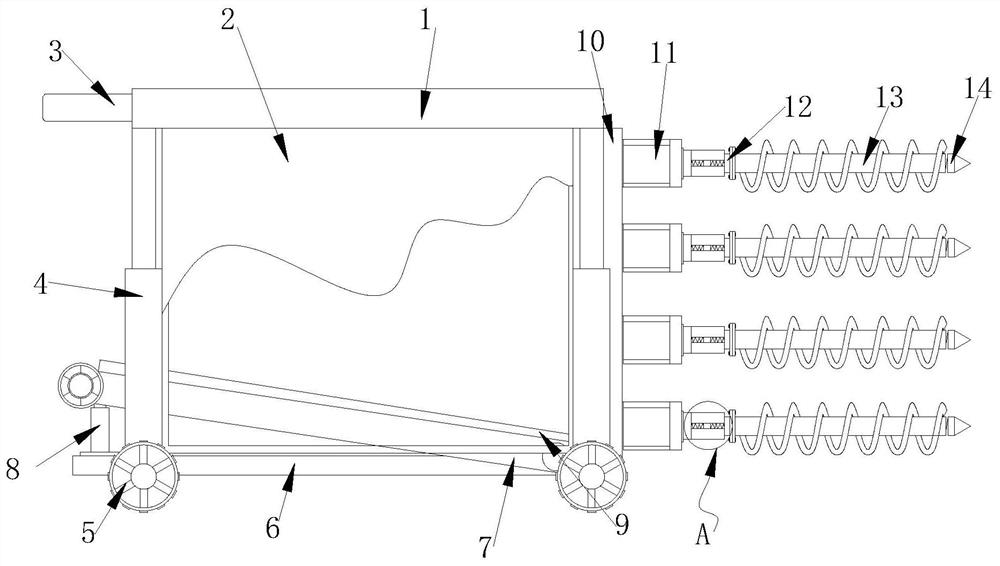

[0040] Such as figure 1 and figure 2 shown;

[0041] figure 1 It is a structural schematic diagram of the present invention;

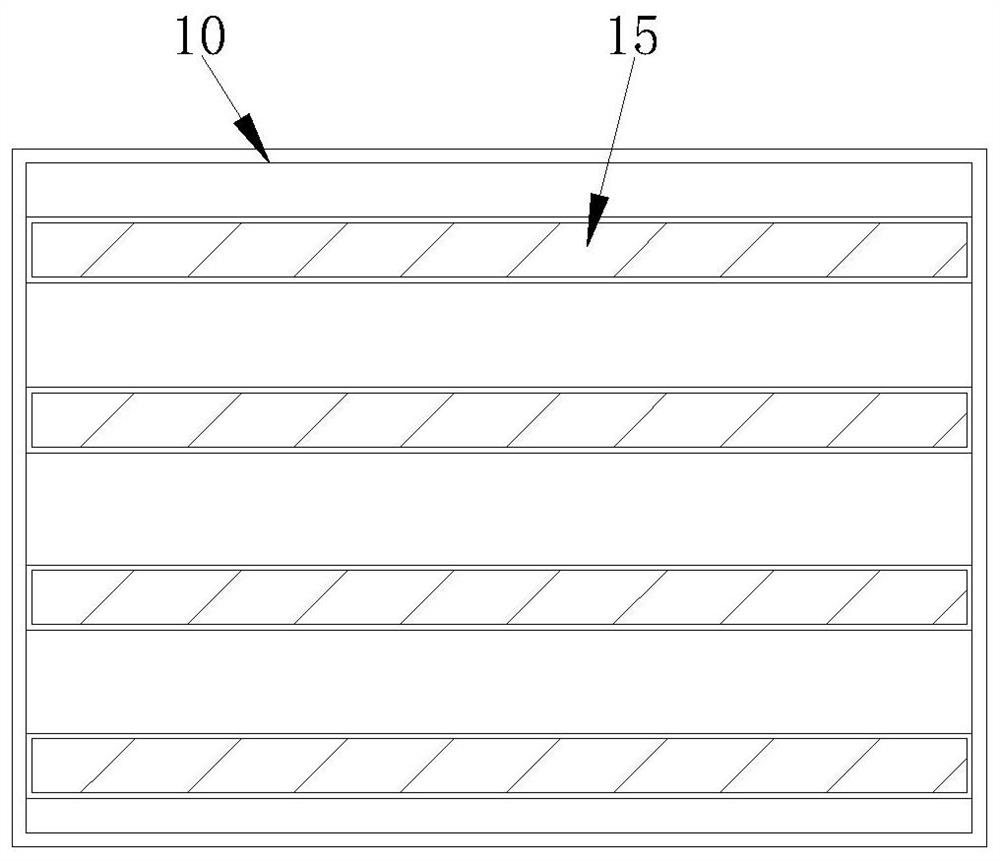

[0042] figure 2 It is a side view of the fixing frame in the present invention;

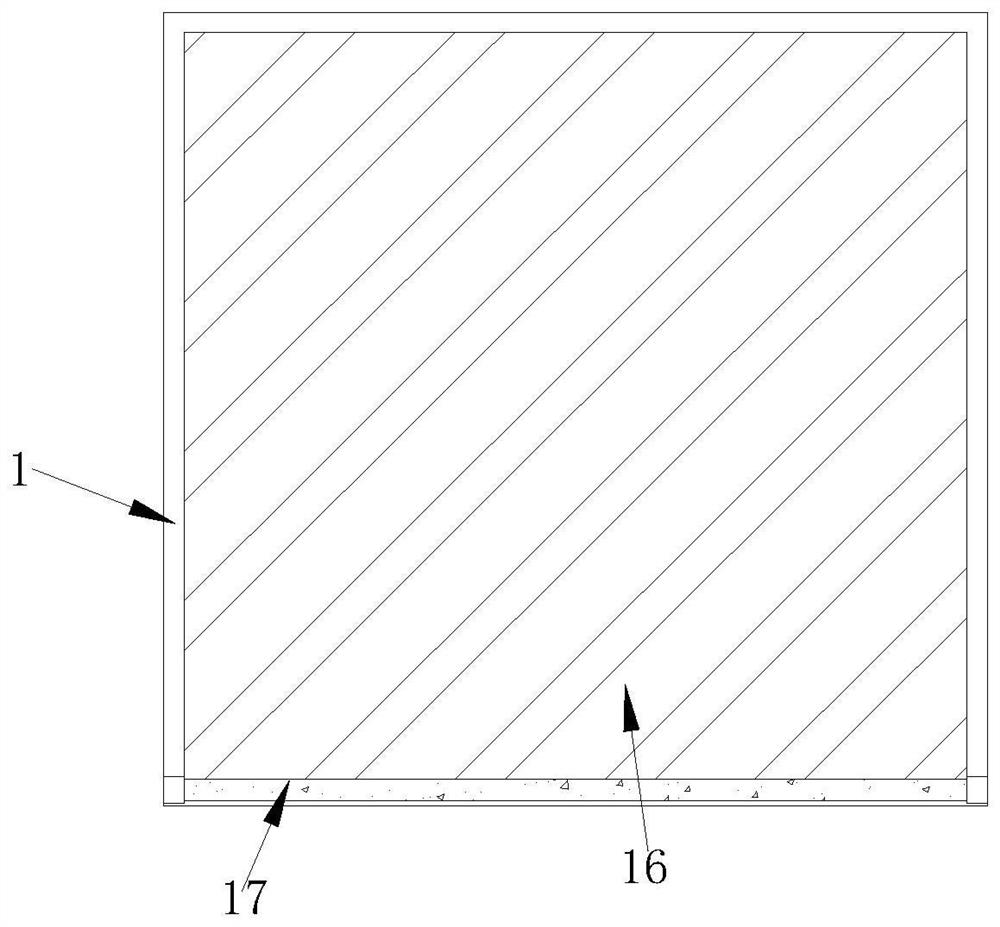

[0043] A tunneling device for coal mining, comprising a fixed plate 1, hydraulic rods 4 are installed at the four corners of the bottom surface of the fixed plate 1, the telescopic shafts of the four hydraulic rods 4 are fixedly connected with the fixed plate 1, and are located on the fixed plate 1 A fixed frame 10 is installed between two symmetrical hydraulic rods 4 on the right side of the bottom surface, and a plurality of motors 11 are installed on the end face of the fixed frame 10. The output shaft of the motor 11 is fixedly connected with a screw rod 13, and four hydraulic rods 4 There is a conveying frame 7 between them, the bottom ends of the four hydraulic rods 4 are equipped with walking wheels 5, the front and back of the fixed plate 1 are equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com