A joint monitoring method for cutter head damage of shield machine

A technology of joint monitoring and shield machine, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of difficult maintenance and processing, the overall rigidity of the structural form affects the speed and cost of construction and excavation, and achieves narrowing the scope of judgment, It is convenient for human further judgment and the effect of simple steps and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

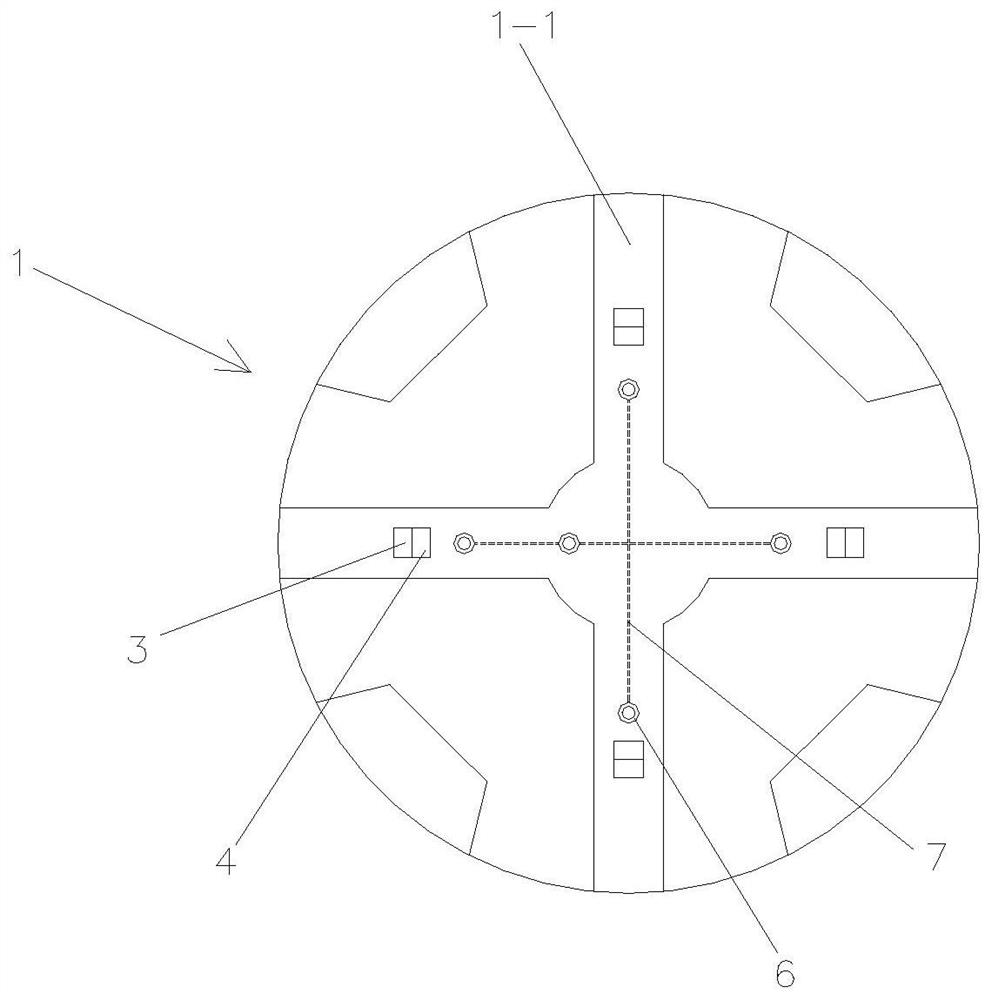

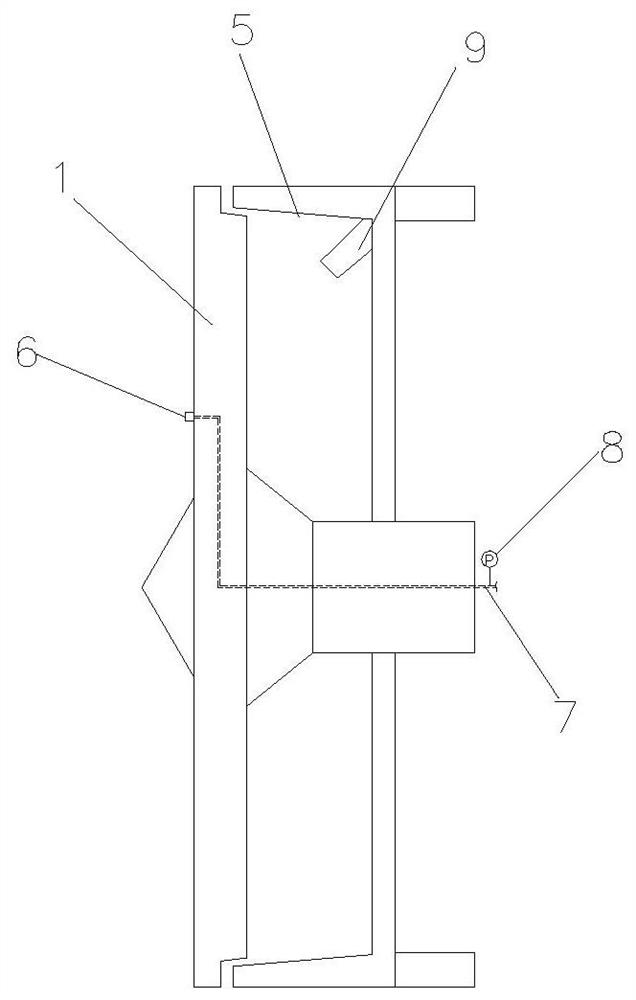

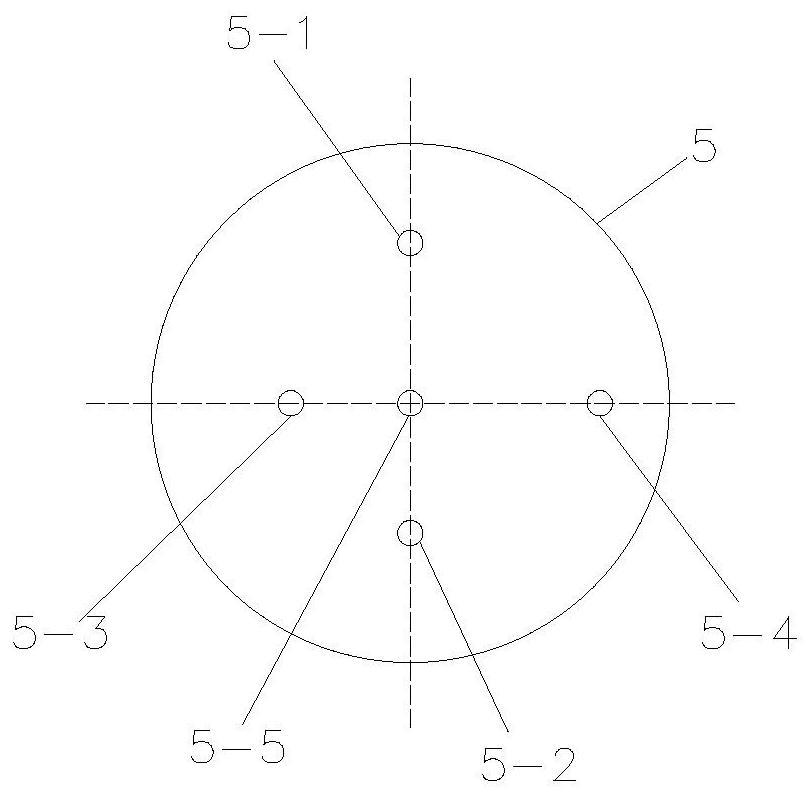

[0107] Such as Figure 1 to Figure 6 A joint monitoring method for shield machine cutter head damage is shown, the method includes the following steps:

[0108] Step 1. Layout of monitoring devices:

[0109] Step 101, laying acceleration sensors 3 on each cutter head spoke 1-1 of the shield machine cutter head 1; wherein, the total number of acceleration sensors 3 is J 1 , and J 1 is a positive integer;

[0110] Step 102, laying out acoustic emission sensors 4 on each cutterhead spoke 1-1 of the shield machine cutterhead 1; wherein, the number of acoustic emission sensors 4 is J 2 , and J2 is a positive integer;

[0111] Step 103, arranging a plurality of temperature sensors in the front shield soil bin 5 of the shield machine; wherein, the number of temperature sensors is J 3 , and J 3 is a positive integer;

[0112] Step 104, arranging a hydraulic wear probe 6 at the center position of each cutter disc spoke 1-1 of the shield machine cutter head and the shield machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com