A multifunctional automatic simulation test device for top corrosion of wet gas pipeline

A simulation test, multi-functional technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as hidden safety hazards, corrosion of the top of the pipeline, difficult to effectively protect the top, etc., to achieve easy sealing and easy disassembly. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0034] 1. The composition of the automatic simulation test device

[0035] The multifunctional moisture duct top corrosion automatic simulation test device provided by the present invention is composed of two major systems: the test loop system, the control and the display system respectively.

[0036] 1. Test loop system

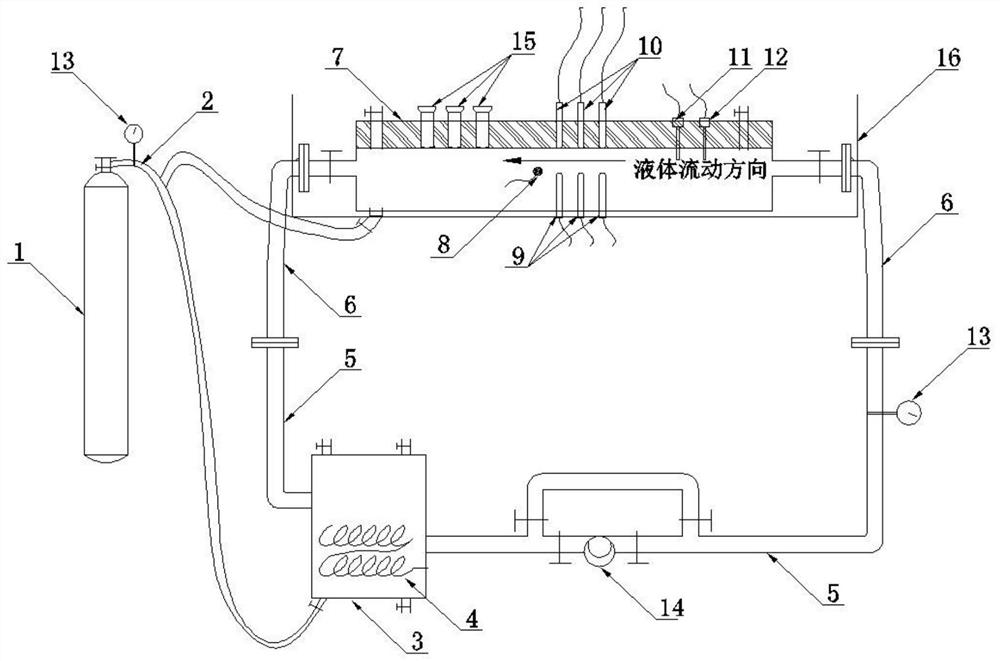

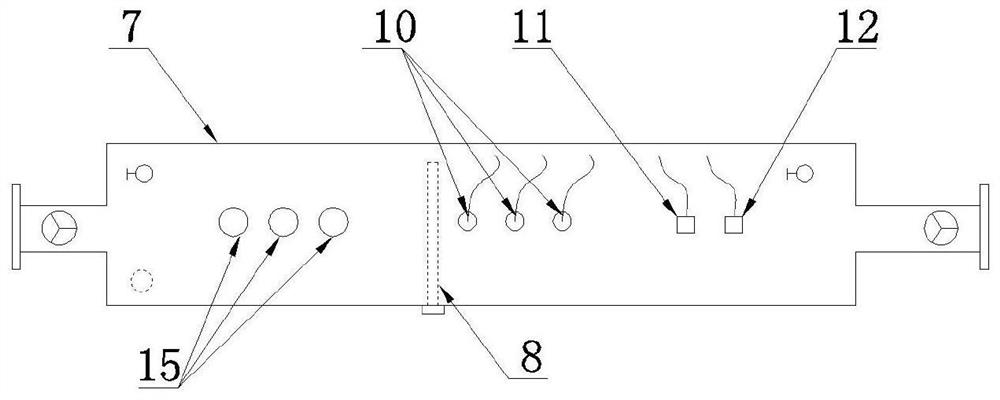

[0037] refer to figure 1 , the test loop system includes: gas cylinder 1, gas hose 2, deposition tank 3, electric heater 4, fixed tube 5, flexible composite tube 6, test tube 7, auxiliary electrode 8, reference electrode 9, working electrode 10 , temperature probe 11 , pressure probe 12 , flow meter 13 , flow pump 14 and thermostatic bath 16 .

[0038]The deposition tank 3 is made of polytetrafluoroethylene, corrosion-resistant alloy or PVC, and is used to hold the test medium (simulated solution) and precipitate solid pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com