Electrolysis and electric spark synchronous combined wire-electrode cutting processing device

A technology of cutting processing and compound line, which is applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of affecting processing accuracy, limiting processing efficiency, and low processing efficiency, so as to achieve good processing quality, solve electrode loss, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

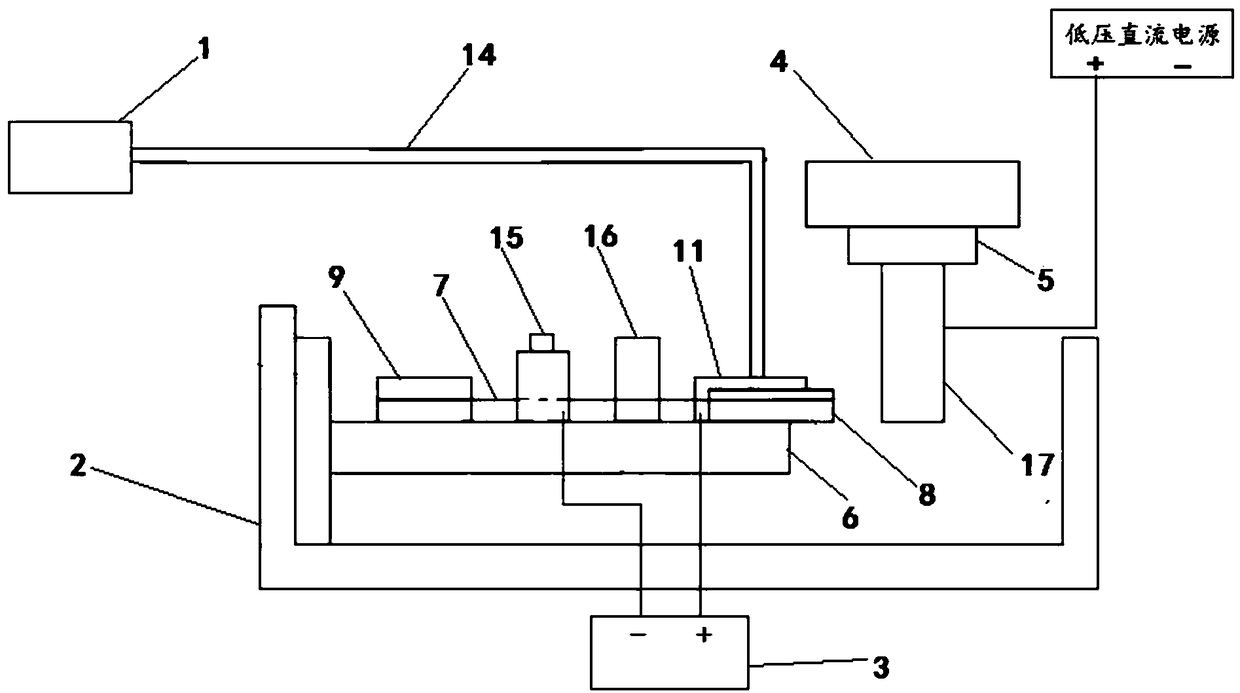

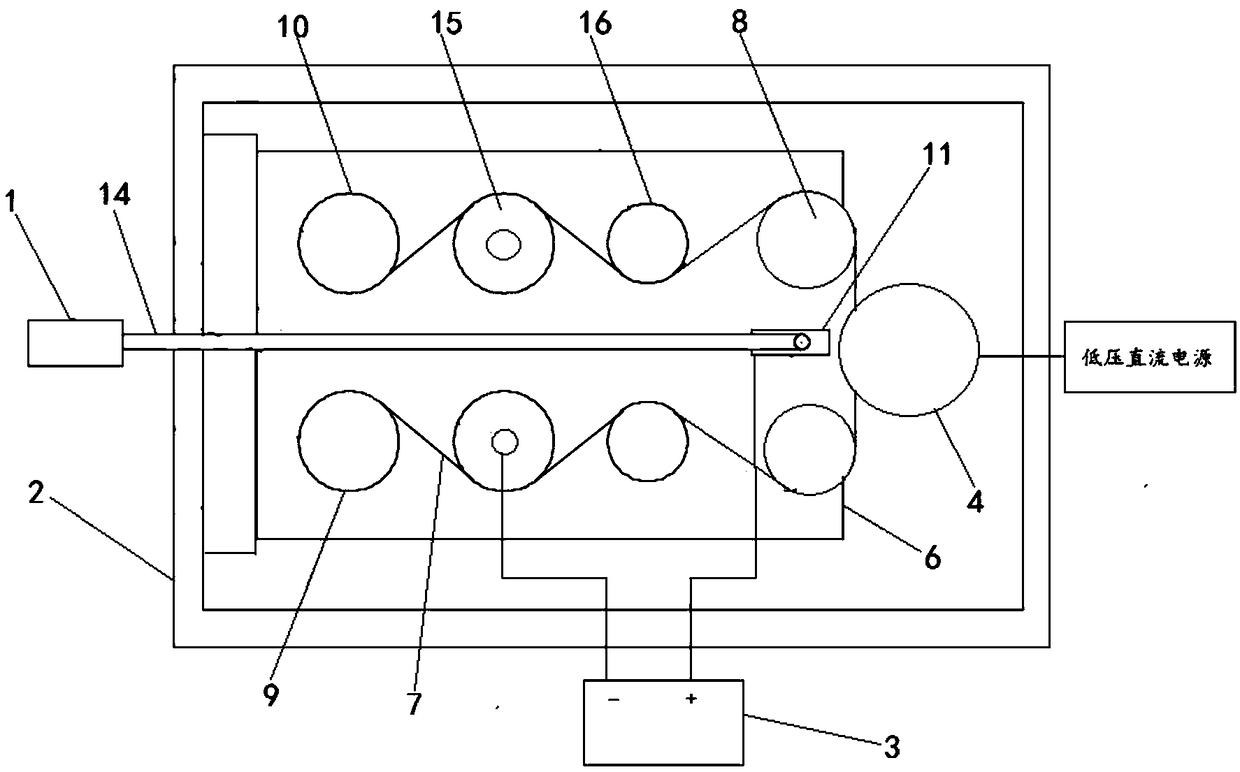

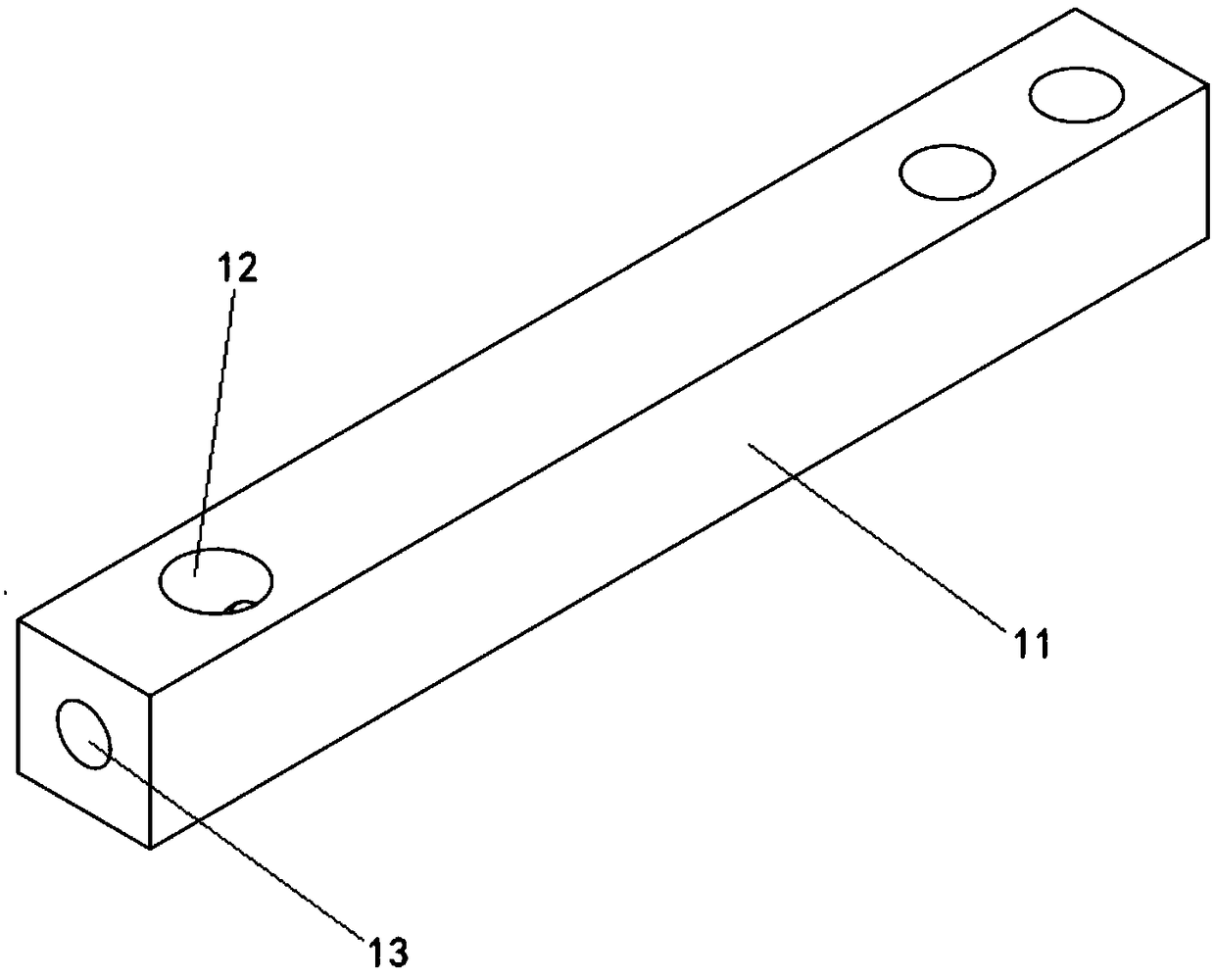

[0022] Please refer to Figure 1 to Figure 3 , an electrolytic EDM synchronous compound wire cutting processing device, comprising an electrolyte supply module 1, an electrolytic tank 2, a high-voltage pulse power supply 3, a wire feeding mechanism, a rotating main shaft 4, and a chuck 5 fixed at the lower end of the rotating main shaft 4;

[0023] The wire running mechanism includes a horizontal platform 6 and an electrode wire 7 arranged in the electrolytic cell 2, a pair of guide wheels 8, a rotary damper 9 and a motor 10 are arranged on the horizontal platform 6, and the rotary damper 9 and the motor 10 are opposite to each other. Fixed on the horizontal platform 6, one end of the electrode wire 7 is wound on the rotating shaft of the rotary damper 9, and the other end of the electrode wire 7 is fixed on the rotating shaft of the motor 10 after winding around a pair of guide wheels 8, and the pair of guide wheels 8 are opposite to each other. Ground is set on the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com