A kind of palladium-based membrane whose surface covers molecular sieve membrane and preparation method thereof

A surface covering and molecular sieve technology, applied in the field of membrane separation, can solve the problems of easy poisoning, inactivation, corrosion and wear of palladium-based hydrogen permeable membranes, and achieve the effect of broad-spectrum resistance to poison erosion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

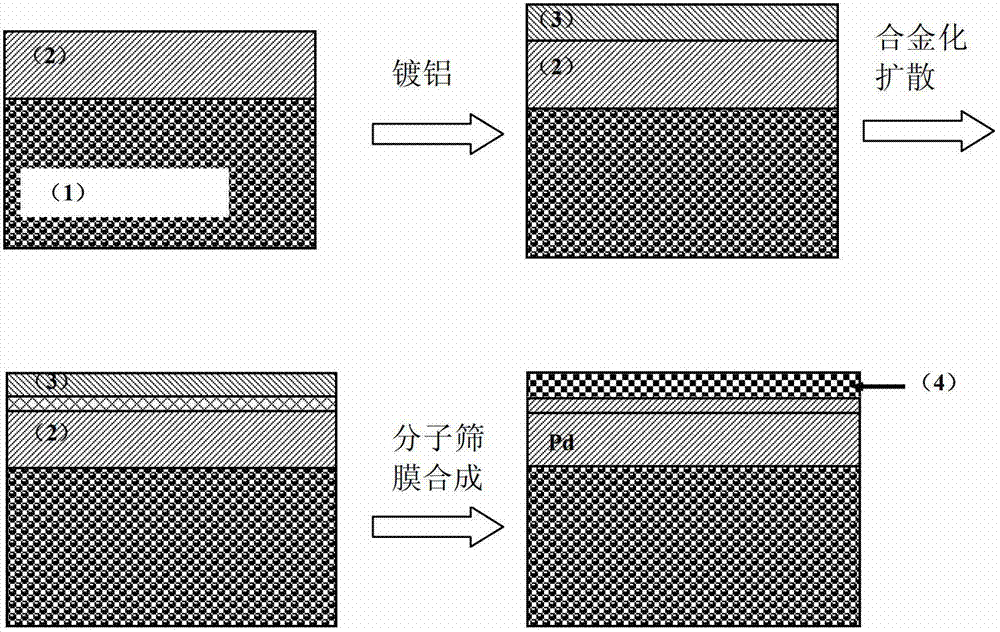

[0034] Aluminum plating: a 1um aluminum film is plated on the surface of the palladium film (12mm in diameter) of the palladium film / porous ceramic support by vacuum sputtering.

[0035] Alloy diffusion: In nitrogen, the temperature is raised to 300°C at a rate of 2°C / min, then switched to hydrogen, and the temperature is raised to 400°C at 1°C / min, kept at a constant temperature for 2 hours, then switched back to nitrogen, and the temperature is naturally lowered.

[0036] Molecular sieve seed crystals were prepared as follows: NaOH (33.0g) and deionized water (189g) were mixed to form NaOH solution, poured into aluminum powder (1.5g), dissolved and filtered to remove impurities, and the silica sol (30wt%, 11.1 g) Slowly drop in, stir at room temperature for 2 hours, then pour the solution into a reaction synthesis kettle, crystallize at 40°C for 17 hours, wash with deionized water after synthesis, centrifuge for 5 times, and dry at 120°C for use.

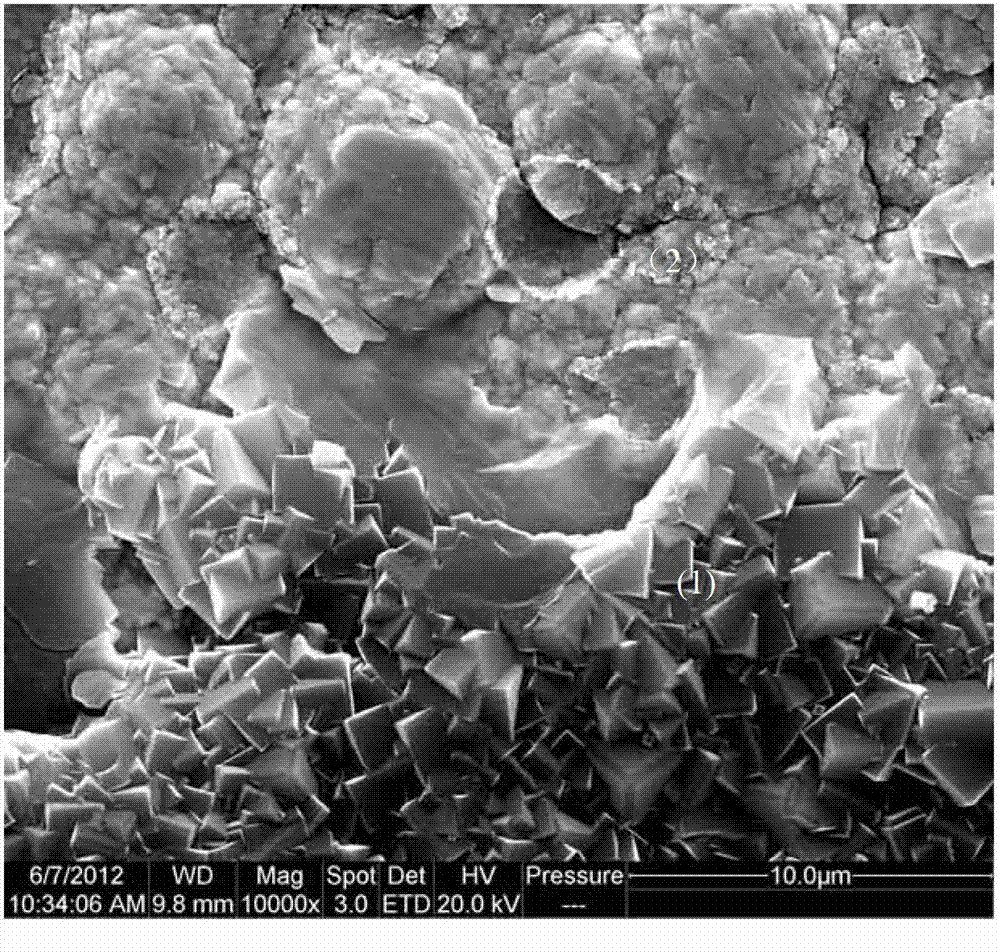

[0037] The molecular sieve...

Embodiment 2

[0041] Salt corrosion resistance test: the 4A molecular sieve membrane palladium membrane prepared on the surface of the palladium membrane in the above examples was treated in 60°C 0.05M KCl solution for 4h, then cleaned in 90°C deionized water for 2h, and then washed at 400°C Drying under a nitrogen atmosphere shows no increase in nitrogen permeability at room temperature.

Embodiment 3

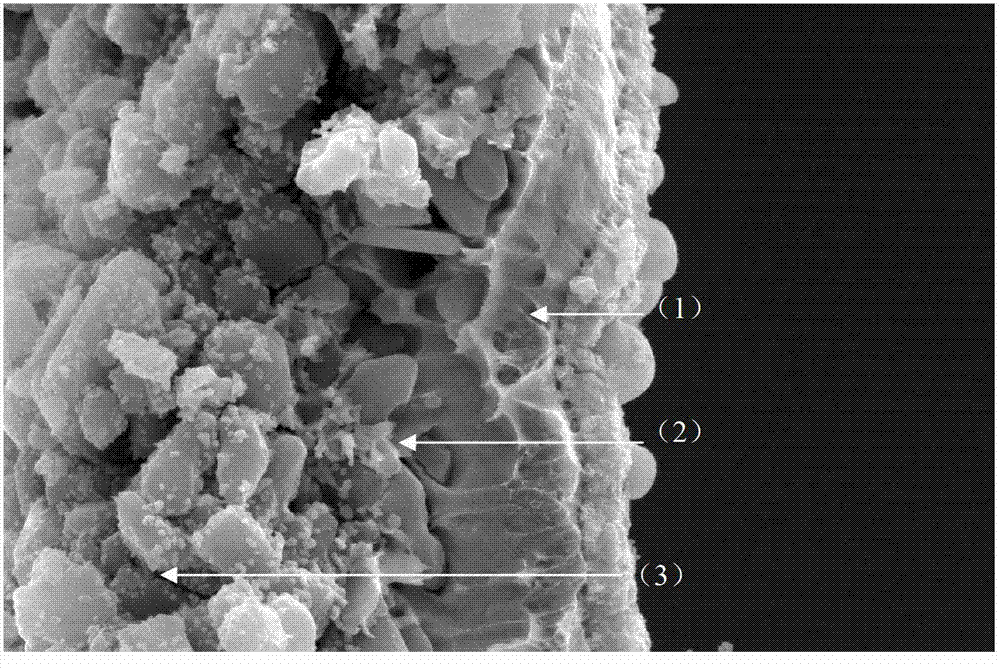

[0043] The 4A type molecular sieve membrane prepared on the surface of the palladium membrane in the above examples is ion-exchanged into a 3A type molecular sieve membrane, and the process is as follows:

[0044] The palladium membrane with the 4A-type molecular sieve membrane was placed in the 0.05M KCl solution, treated at 60°C for 4h, and then washed in 90°C deionized water for 2h to obtain a palladium membrane covering the 3A-type molecular sieve membrane. This 15mm long 3A type molecular sieve palladium membrane has a nitrogen permeability of 11ml / min at 300°C, which is less than the 40ml / min nitrogen permeability of the reference palladium membrane. The hydrogen permeation data of the 3A molecular sieve palladium membrane at 500°C is shown in the table below, which shows a higher hydrogen permeation rate than the reference original palladium membrane.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com