Drying upender for feed processing

A feed processing and turning machine technology, used in dryers, drying, non-progressive dryers, etc., can solve problems such as hidden dangers and high safety of hanging baskets, and achieve easy cleaning, improve drying efficiency, and improve shaking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

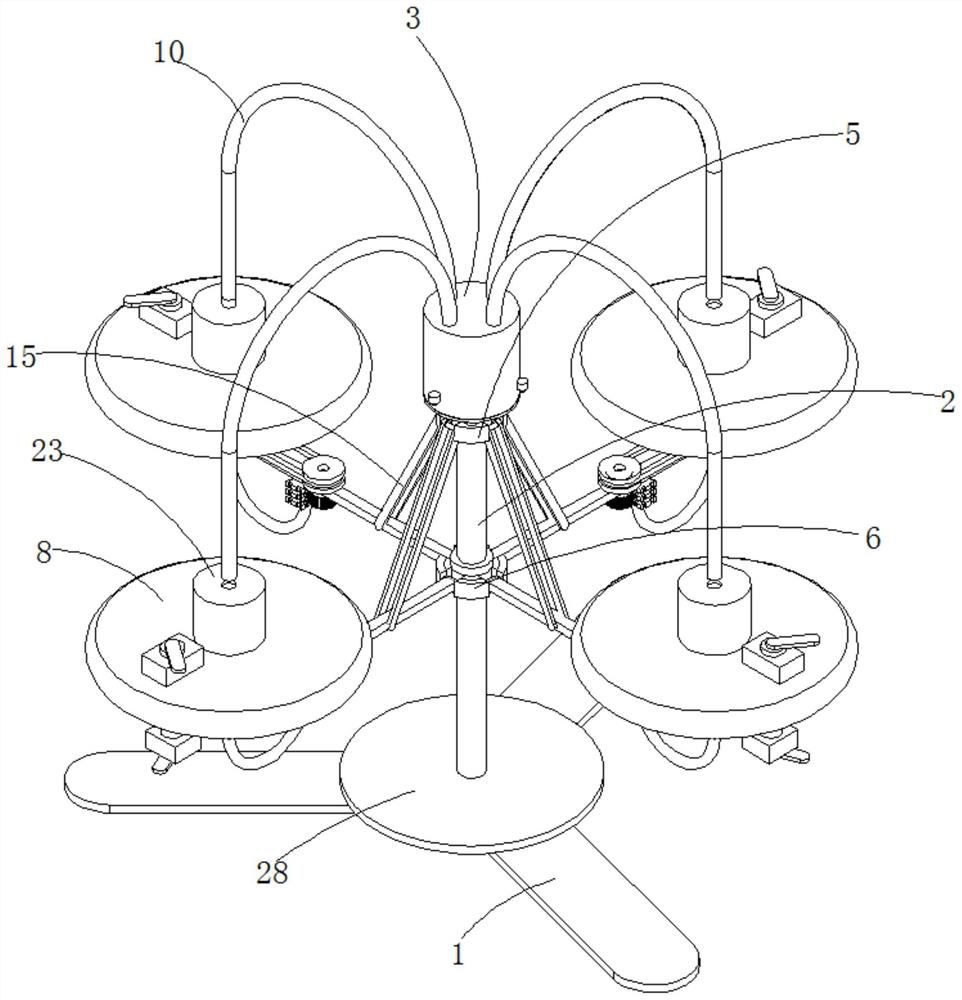

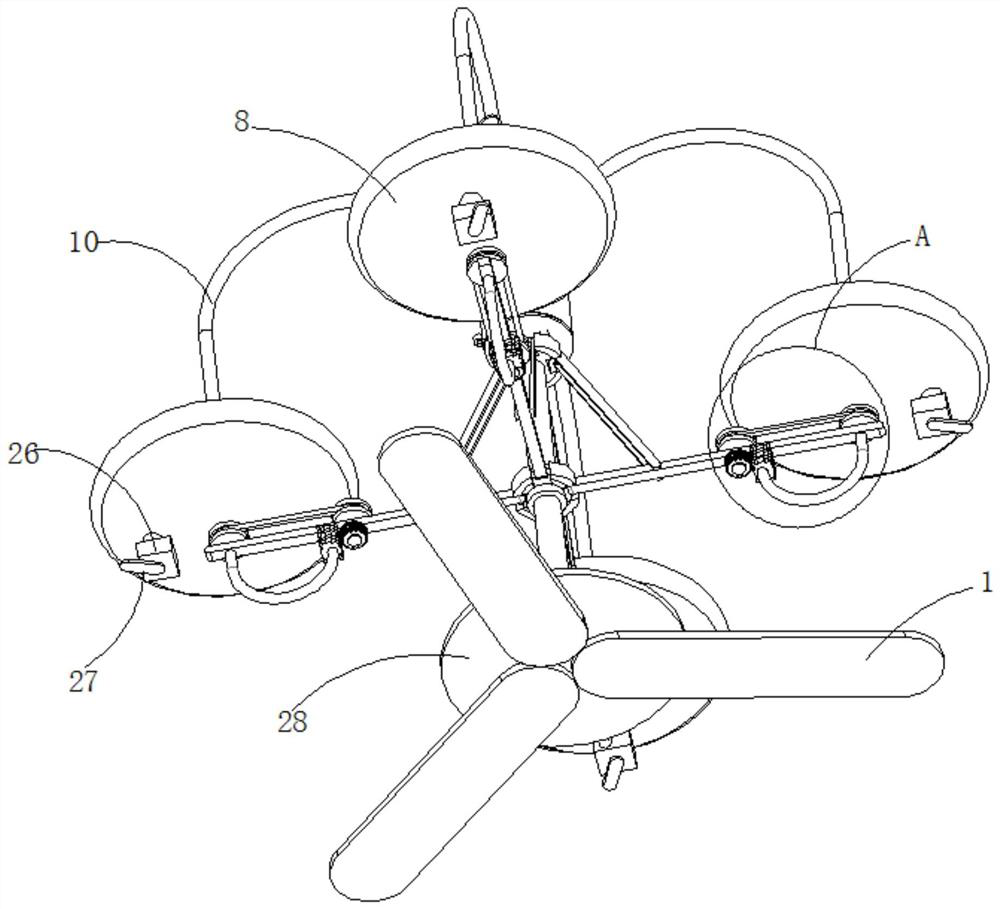

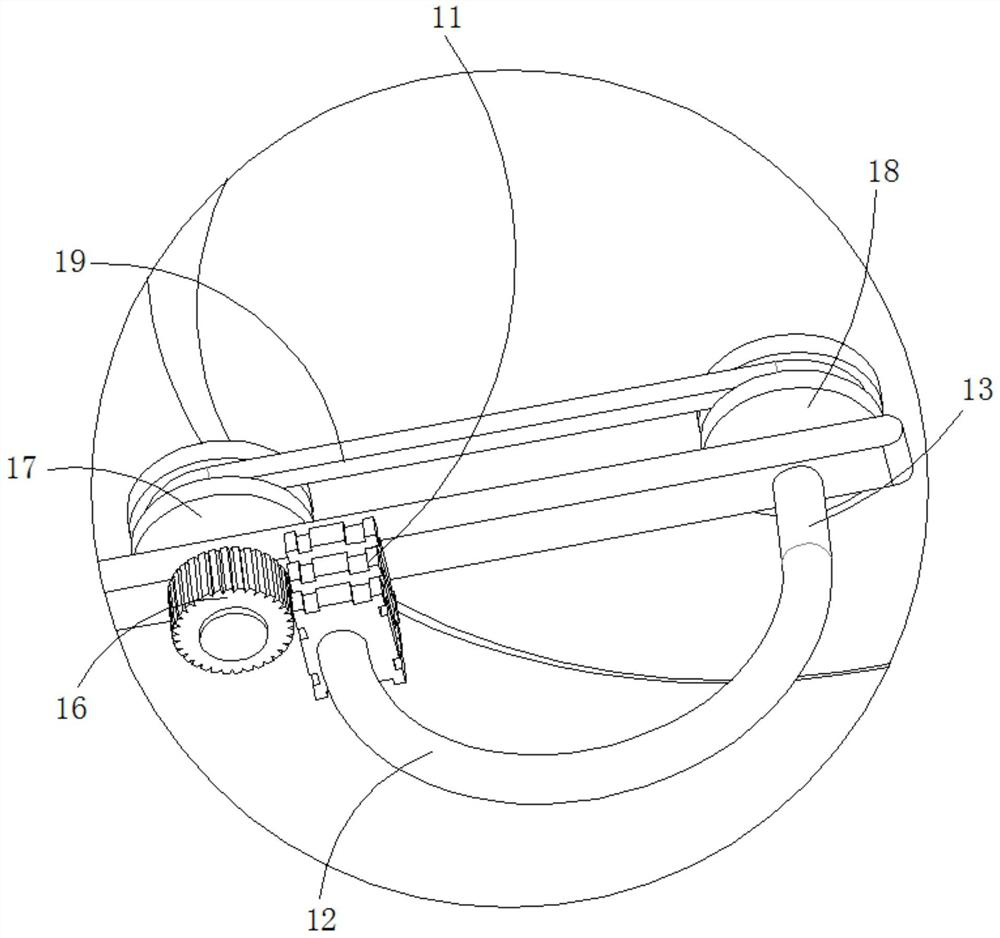

[0031] refer to Figure 1-6, a drying and turning machine for feed processing, comprising a fixed frame 1, a vertically arranged fixed rod 2 is affixed to the center of the top of the fixed frame 1, and an air cylinder 3 is affixed to the end of the fixed rod 2 away from the fixed frame 1. 3 The outer wall near the top of the fixed rod 2 is provided with evenly distributed pressure relief valves 4, the outer wall of the fixed rod 2 is connected with the upper sliding seat 5 and the lower fixed seat 6 in sequence along the vertical direction, and the upper sliding seat 5 is slidably connected to the fixed rod 2 The outer wall of the lower fixed seat 6 is fixedly connected to the middle section of the fixed rod 2, and the outer edge of the lower fixed seat 6 is rotatably connected with an evenly distributed mounting plate 7, and the end of the mounting plate 7 away from the lower fixed seat 6 is provided with a rotating assembly. The rotating end of the feed drying bucket 8 is f...

Embodiment 2

[0043] refer to Figure 1-6 , a drying and turning machine for feed processing, comprising a fixed frame 1, a vertically arranged fixed rod 2 is affixed to the center of the top of the fixed frame 1, and an air cylinder 3 is affixed to the end of the fixed rod 2 away from the fixed frame 1. 3 The outer wall near the top of the fixed rod 2 is provided with evenly distributed pressure relief valves 4, the outer wall of the fixed rod 2 is connected with the upper sliding seat 5 and the lower fixed seat 6 in sequence along the vertical direction, and the upper sliding seat 5 is slidably connected to the fixed rod 2 The outer wall of the lower fixed seat 6 is fixedly connected to the middle section of the fixed rod 2, and the outer edge of the lower fixed seat 6 is rotatably connected with an evenly distributed mounting plate 7, and the end of the mounting plate 7 away from the lower fixed seat 6 is provided with a rotating assembly. The rotating end of the feed drying bucket 8 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap