Power distribution network transformer oil supplementing device

A technology of oil replenishment device and transformer, which is applied in the direction of transformer/inductor cooling, etc. It can solve the problems of manual impurities and introduction of transformers, etc., and achieve the effect of improving oil replenishment efficiency, reducing waste and loss, and being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

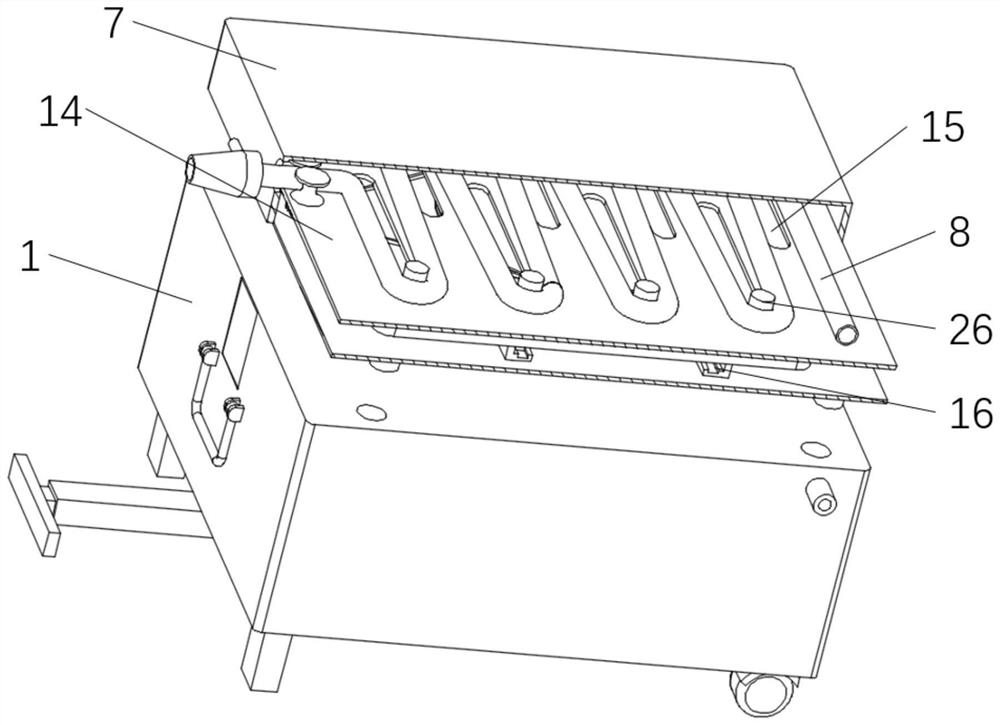

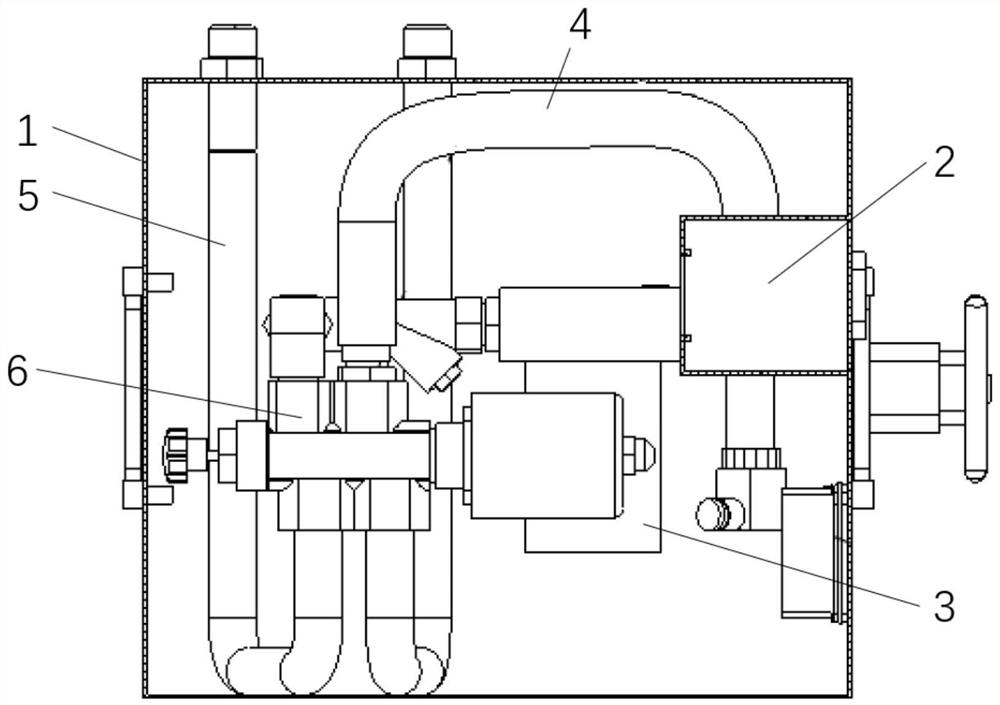

[0032] like Figure 1 to Figure 9 As shown, the present invention provides a distribution network transformer oil supply device, including a movable box 1, the box 1 is provided with an oil storage tank 2, an oil pump 3, an oil suction pipe 4, an oil outlet pipe 5 and a multi-channel replacement Directional valve 6, the oil suction pipe 4 is connected to the oil storage tank 2 and the oil pump 3, the oil outlet pipe 5 is connected to the reversing valve 6, and the reversing valve 6 is connected to the output end of the oil pump 3; the reversing valve 6 is a four-way cross structure A reversing valve 6; a rechargeable mobile power supply is provided in the box body 1 to provide a power source for the oil pump 3; a storage box 7 is provided on the box body 1, and a refueling pipe 8 is stored in the storage box 7, and one end of the refueling pipe 8 is connected to On the joint of the oil outlet pipe 5, the other end of the oil filling pipe 8 is provided with an oil filling joint...

Embodiment 2

[0041] like Figure 8 and Figure 9 As shown, in combination with the technical solution of Embodiment 1, in this embodiment, a plurality of teeth 200 are evenly distributed on the first rack bar 22 and the second rack bar 23, and are located on both sides of the first rack bar 22 and the second rack bar 23. The end is elastically hinged with a movable tooth 201, and the movable tooth 201 is connected to the two ends of the first gear rod 22 and the second gear rod 23 by a torsion spring 202, so that the movable tooth 201 can be returned by the torsion spring 202; by setting the movable tooth 201 so that when the toothed plate 21 pushes the first toothed rod 22 and the second toothed rod 23 to move to the extreme end, when the toothed plate 21 continues to rotate, the first toothed rod 22 and the second toothed rod 23 will not continue to move, so that When the filling pipe 8 is discharged; after the first pull rod 24 and the second pull rod 25 are relatively contracted, the ...

Embodiment 3

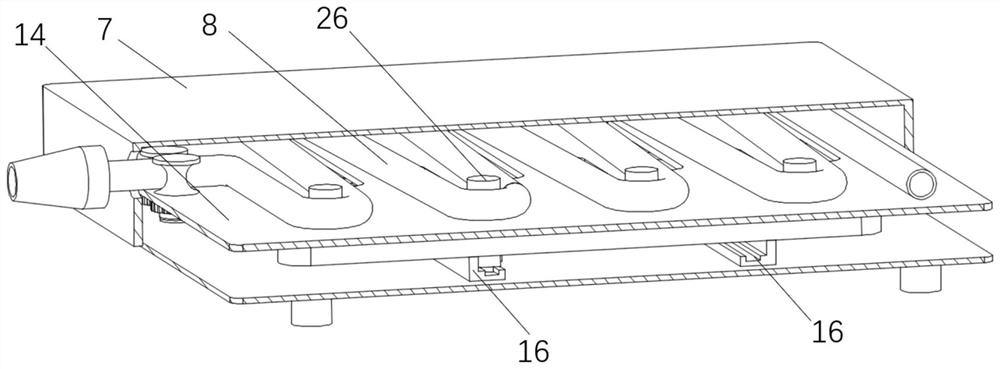

[0044] like image 3 and Figure 4 As shown, in combination with the technical solution of Embodiment 2, in this embodiment, the storage box 7 is provided with a partition 14, the partition 14 is provided with a limiting groove 15, and the guide column 26 is located in the limiting groove 15, so as to guide The slots limit the guide column 26; the storage box 7 is also provided with a limit track 16, and the first rack 22 and the second rack 23 are provided with strip-shaped limit protrusions, and the limit protrusions are located on the limit track 16. In order to limit the linear movement of the first gear rod 22 and the second gear rod 23 through the limit rail 16, so as to avoid the problem that the first gear rod 22 and the second gear rod 23 are out of engagement with the toothed disc 21 .

[0045] Specifically, it also includes a filter screen arranged on the oil suction pipe 4 to filter the transformer oil in the oil storage tank 2, thereby reducing impurities in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com