Method for improving sealing performance of membrane electrode

A sealing performance, membrane electrode technology, used in sealing/supporting devices, fuel cell components, circuits, etc., can solve problems such as poor electrode sealing, achieve good air tightness, good adhesion, and ensure air tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

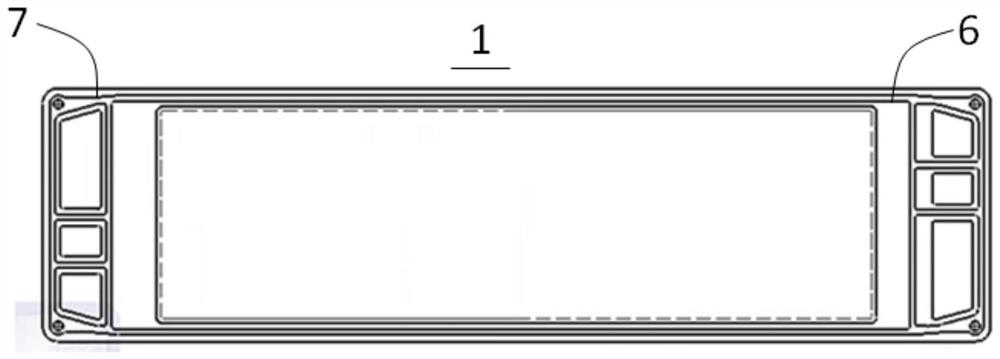

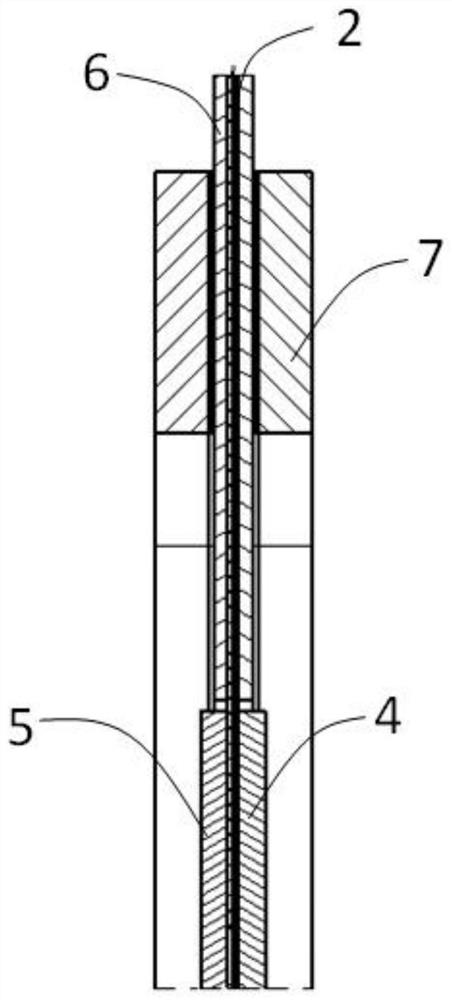

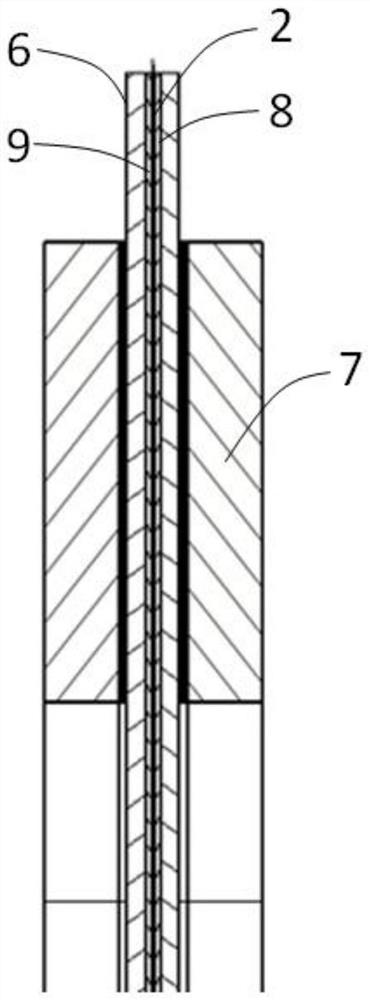

[0027] Please refer to figure 1 , with reference to Figure 2 to Figure 4 , the application provides a method for improving the sealing performance of membrane electrodes, comprising the following steps:

[0028] S1, wrapping an inner frame 3 on the outer surface of the proton exchange membrane 2;

[0029] S2, combining the two opposite first outer surfaces of the inner frame 3 with the cathode gas diffusion layer 4 and the anode gas diffusion layer 5 under a hot press to form a membrane electrode 1; wherein, the hot pressing temperature of the hot press is 110-160℃, pressure 5-10bar, hot pressing time 30s-5min;

[0030] S3, wrapping a layer of outer frame 6 on the two second outer surfaces opposite to the inner frame 3;

[0031] S4, a layer of sealing ring 7 is pasted on the two opposite outer surfaces of the outer frame 6 through double-sided adhesive tape.

[0032] It should be noted that, in this embodiment, in step S1, the inner frame 3 is generally made of a film wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com