Sedimentation device for sewage treatment

A technology of sedimentation device and sewage treatment, applied in the feeding/discharging device of sedimentation tank, sedimentation separation, sedimentation tank, etc., can solve the problem of adding sewage, etc., to achieve the effect of improving efficiency and increasing sedimentation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

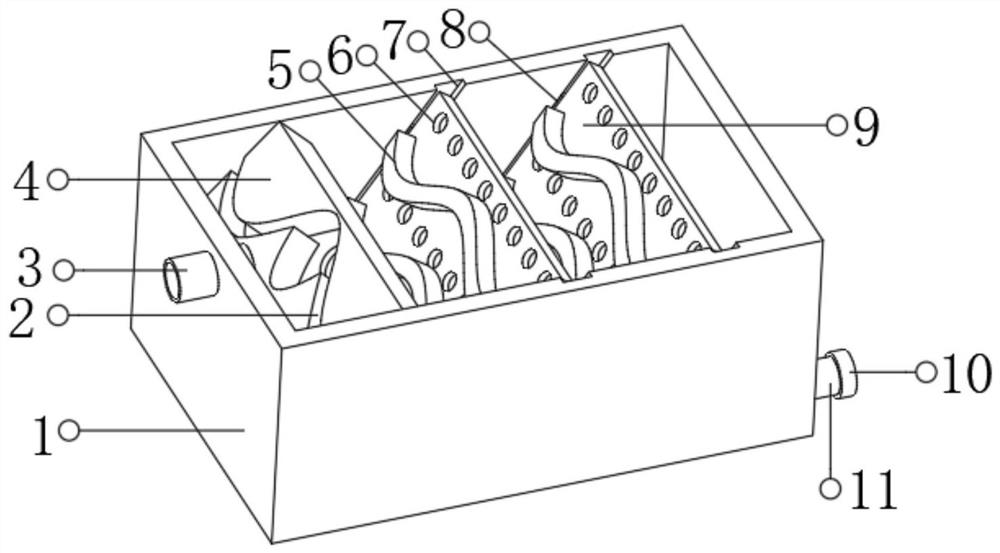

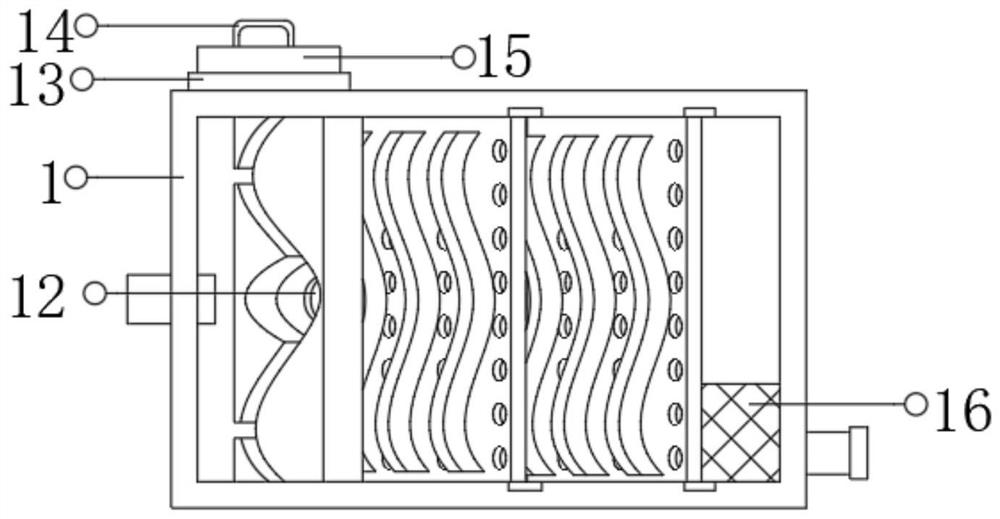

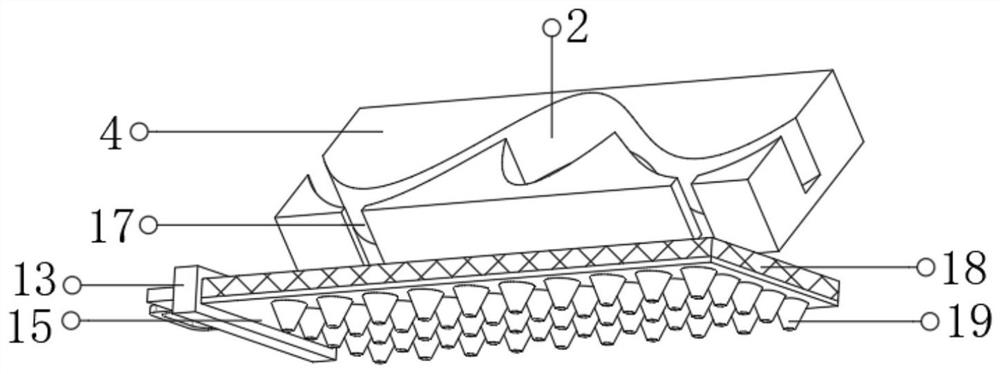

[0026] refer to Figure 1-4 , a sedimentation device for sewage treatment, comprising a sedimentation tank 1, the top of the outer wall of the sedimentation tank 1 is connected with a water inlet pipe 3 by bolts, and the water inlet pipe 3 runs through the sedimentation tank 1 and extends to the inside, and between the inner walls of the two opposite ends of the sedimentation tank 1 The slant plate 4 is connected by bolts, and the outer wall of the slant plate 4 facing the water inlet pipe 3 has a groove 2. The groove 2 is a mountain-shaped structure, and the inner wall of the bottom of the groove 2 is located in the middle. There is a deep groove 12 There are water outlets 17 at the lower ends of both sides of the groove 2 of the mountain-shaped structure, and a horizontal plate 15 is connected by bolts between the inner walls of the opposite ends of the sedimentation tank 1, and the horizontal plate 15 is located directly below the water outlet 17, and the horizontal plate 1...

Embodiment 2

[0030] refer to Figure 5 , a sedimentation device for sewage treatment, further comprising a water tank 20 connected by bolts to the outer wall on one side of the sedimentation tank 1 near the top, and a telescopic tube 22 connected to the top outer wall of the water tank 20 by bolts, and a nozzle connected to one end of the telescopic pipe 22 by bolts twenty one.

[0031]Working principle: when in use, the sewage that needs to be settled is introduced into the sedimentation tank 1 from the water inlet pipe 3, and the sewage enters from the water inlet pipe 3 and falls on the deep groove 12 in the groove 2 of the inclined plate 4, and the sewage After buffering, on the inflow groove 2, the unique mountain-shaped groove 2 can buffer the sewage again, and then flow into the filter plate 18 from the water outlet 17, and the filter plate 18 filters out the larger pollutants contained in the sewage. Impurities, when the filter plate 18 accumulates more impurities, the filter plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com