Solid-liquid separation device applied to sewage treatment system

A sewage treatment system and solid-liquid separation technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of filter blockage, inability to filter solid impurities in the filter, and affect the efficiency of sewage treatment, etc., to prevent Deposition, good anti-slip effect, anti-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

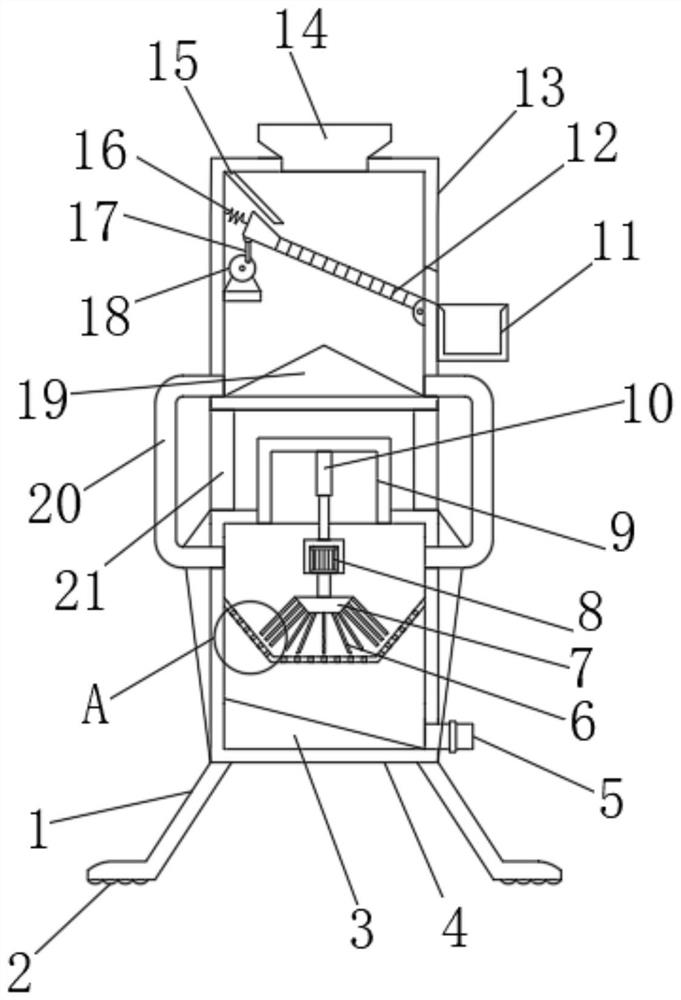

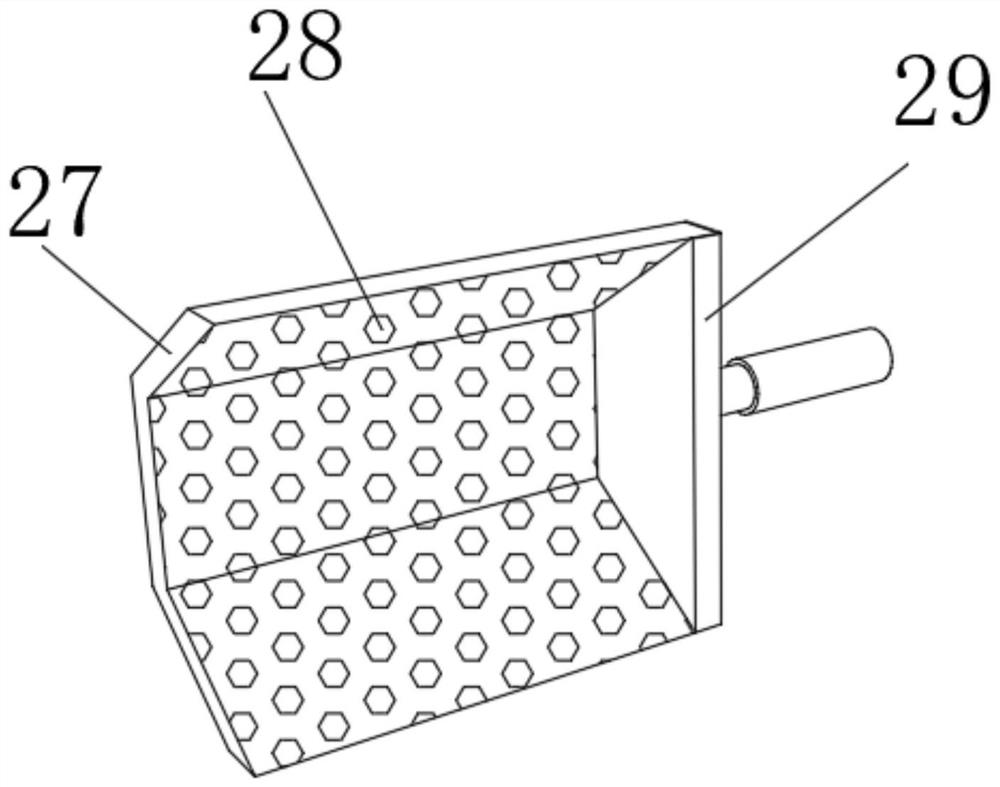

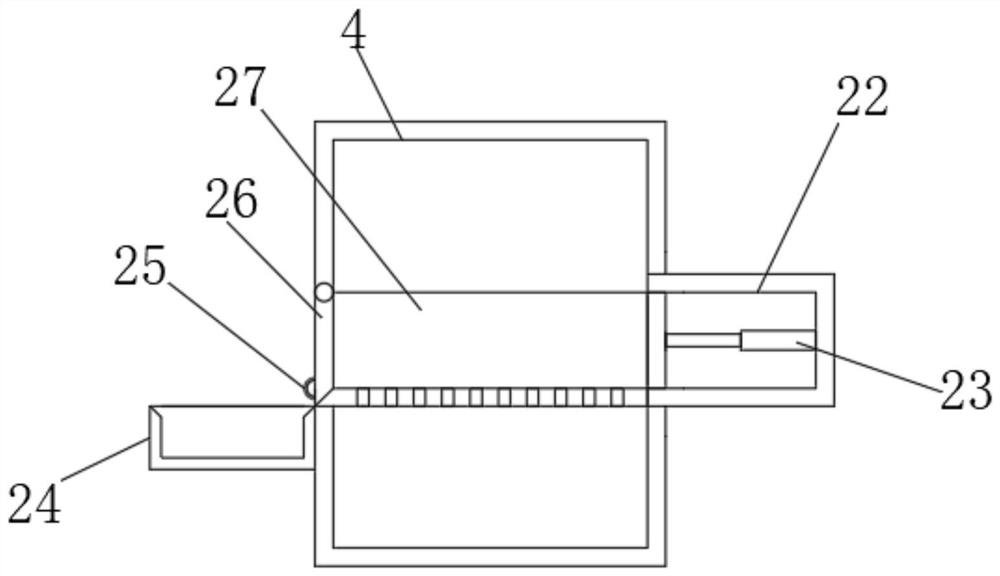

[0029]Refer toFigure 1-4, A solid-liquid separation device applied to a sewage treatment system, comprising a second separation box 4, the two inner walls of the second separation box 4 are fixed with the same filter tank 27 by screws, and the inner wall of the filter tank 27 is provided with filter holes 28. The top outer wall of the second separation box 4 is fixed with a fixed box 9 by screws, and the top inner wall of the fixed box 9 is fixed with an electric telescopic rod 10 by screws, and one end of the piston rod of the electric telescopic rod 10 is fixed with a motor 8 by screws, and The output shaft of the motor 8 is connected with a trapezoidal fixed block 7 through a coupling. The bottom outer wall of the trapezoidal fixed block 7 is provided with five to ten stirring rods 6, and the five to ten stirring rods 6 are arranged in a fan-shaped structure. The second separation box A mounting box 22 is fixed on one side of the outer wall of 4 by screws, and the inner wall of t...

Embodiment 2

[0039]Refer toFigure 5 , A solid-liquid separation device applied to a sewage treatment system. Compared with the first embodiment, this embodiment further includes a hydraulic rod 30 fixed to the bottom outer wall of the second separation box 4 by screws, and one end of the piston rod of the hydraulic rod 30 A fixed suction cup 31 is fixed by screws.

[0040]The piston rod of the control hydraulic rod 30 is extended, and the fixed suction cup 31 can adsorb the ground to fix the device, which improves the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com