Evaporation coating machine for high-temperature structural ceramic

A technology of steam coating machine and ceramics, which is applied in the direction of ceramic forming machines, coatings, and devices for coating liquid on the surface, etc., which can solve problems such as agglomeration, uneven coating amount of coating wheel, residual coating wheel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

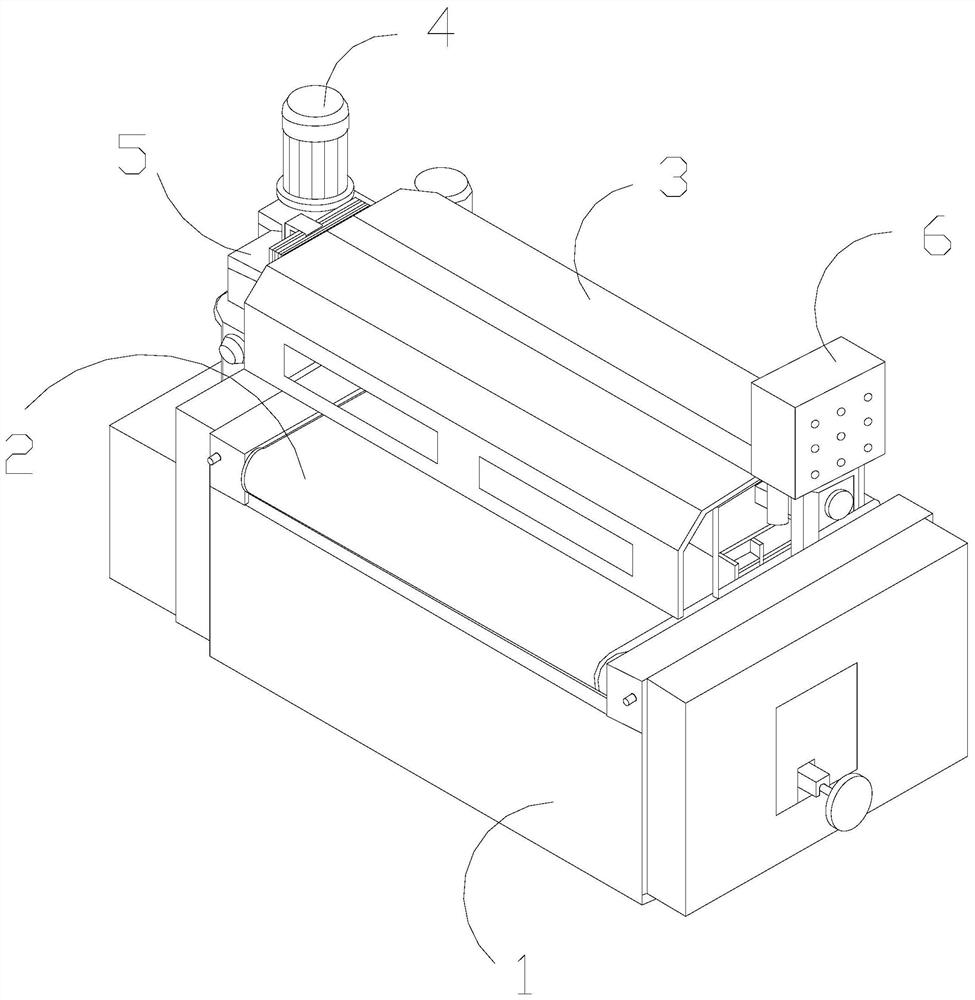

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The invention provides a steam coating machine for high-temperature structural ceramics, the structure of which is provided with a frame 1, a running table 2, a working frame 3, a motor 4, a side connecting shaft 5, and a control panel 6, and the running table 2 is movable on the frame 1, the work frame 3 is connected above the frame 1, the work frame 3 is located above the running platform 2 and is movably matched, the motor 4 is installed on one side of the frame 1, and the side connecting shaft 5 Passing through one side of the working frame 3 , the control panel 6 is installed on the other side of the working frame 3 .

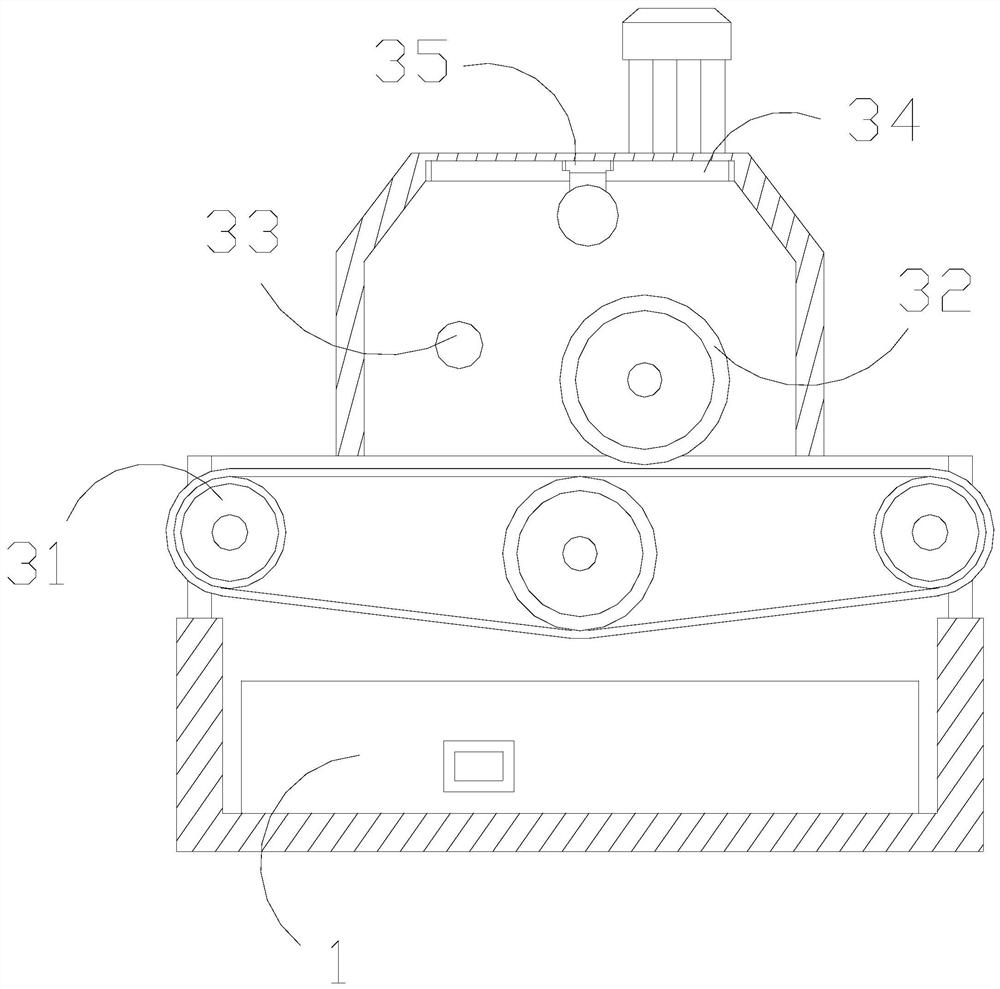

[0029] The working frame 3 is provided with a spreading roller 31, a coating wheel 32, a bearing 33, a top rail 34, and a drop rack 35. The spreading roller 31 is movable on both sides below the working frame 3, and the coating wheel 32 is movably connected to the working frame. Inside the ...

Embodiment 2

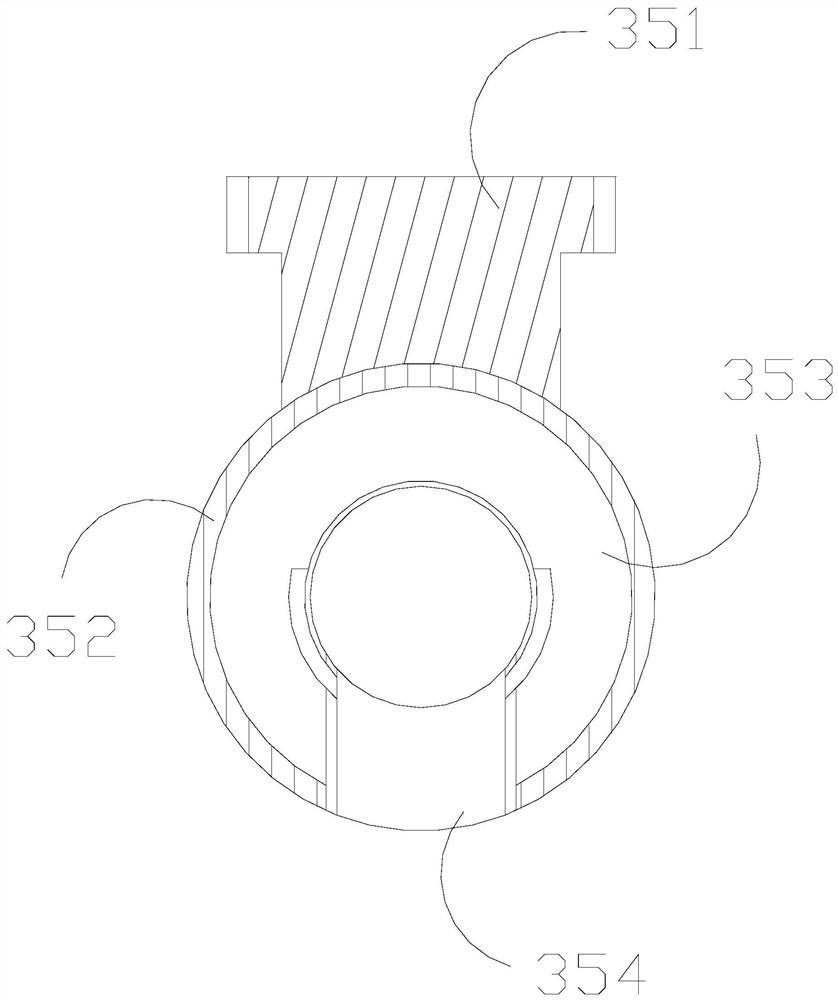

[0035] as attached Figure 6 to attach Figure 7 Shown:

[0036]Wherein, the movable cavity 353 is provided with a hinged swing rod z1, a slamming ball z2, a spring steel z3, and a hinged bearing z4. The bearing z4 is hingedly connected and movably matched. The side support block a3 is connected to the inner end of the hinge swing rod z1 and is movably fitted. There are six hinge swing rod z1 and slamming ball z2, and each two are used as a group for activities. Coordinated, there are three spring steel z3, the lashing ball z2 is in a spherical state, and the hinge swing rod z1 is continuously hinged and oscillated under the elastic action of the spring steel z3, driving the lashing ball z2 to continuously perform impacting activities.

[0037] Wherein, the slamming ball z2 is provided with a solid ring z21, a ring cavity z22, a linkage bag z23, and a pull belt z24. The ring cavity z22 is located outside the center ring z21, and the linkage bag z23 is embedded in the ring ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com