A blackboard trimming device with a safety protection mechanism

A safety protection and edge trimming technology, applied in grinding/polishing safety devices, grinding drive devices, grinding machine parts, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

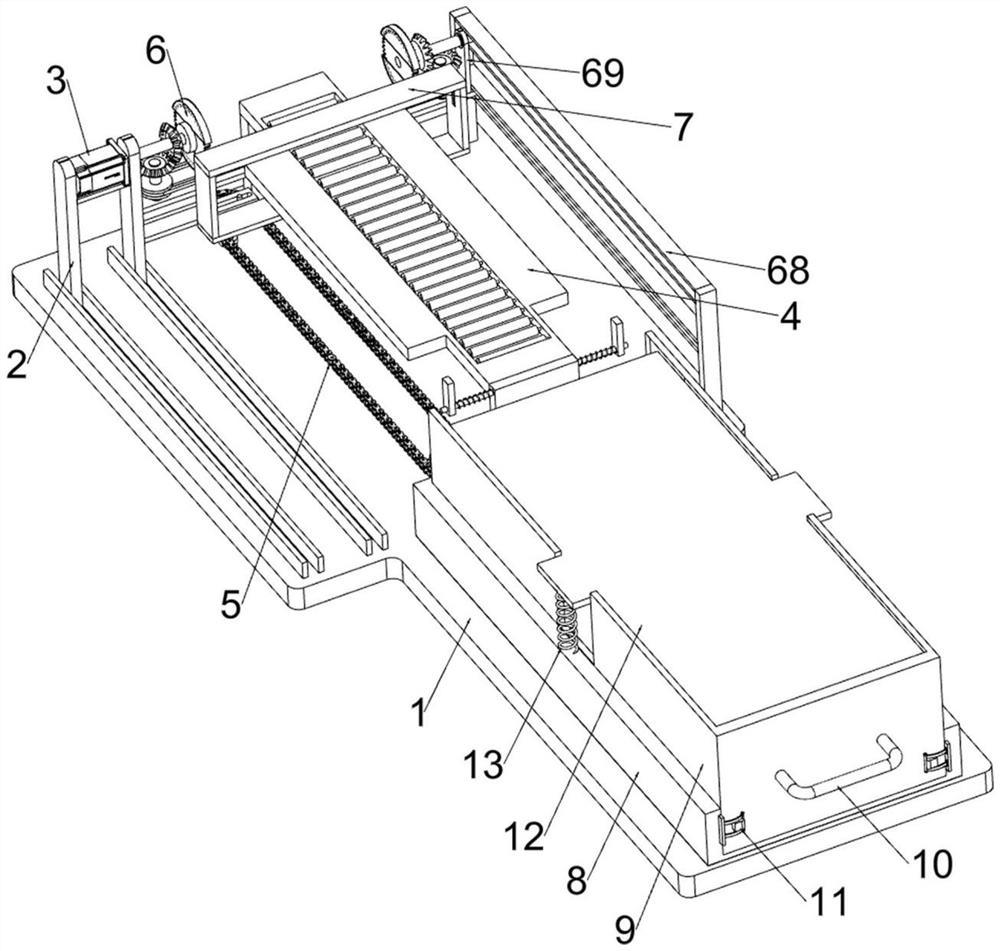

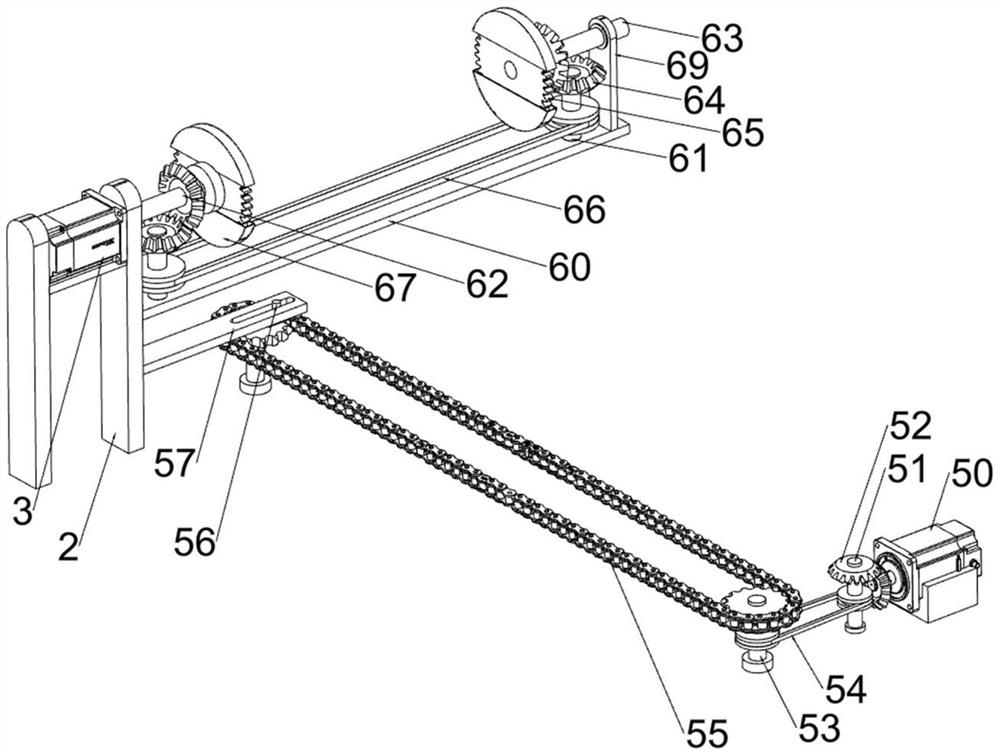

[0023] A blackboard trimming device with a safety protection mechanism, such as figure 1 As shown, it includes a base 1, a support frame 2, a first servo motor 3, a placement mechanism 4, a translation mechanism 5, an edging mechanism 6, and a clamping mechanism 7. The top left front side of the base 1 is slidingly connected to a support frame 2 to support The frame 2 is connected with a first servo motor 3, the left side of the top of the base 1 is provided with a placement mechanism 4, the left side of the top of the base 1 is provided with a translation mechanism 5, the translation mechanism 5 is located below the placement mechanism 4, and the left side of the top of the base 1 is provided with a grinding mechanism. The side mechanism 6 and the placement mechanism 4 are provided with a clamping mechanism 7.

[0024] The staff places the blackboard in the placement mechanism 4, then starts the first servo motor 3 and the translation mechanism 5, the first servo motor 3 driv...

Embodiment 2

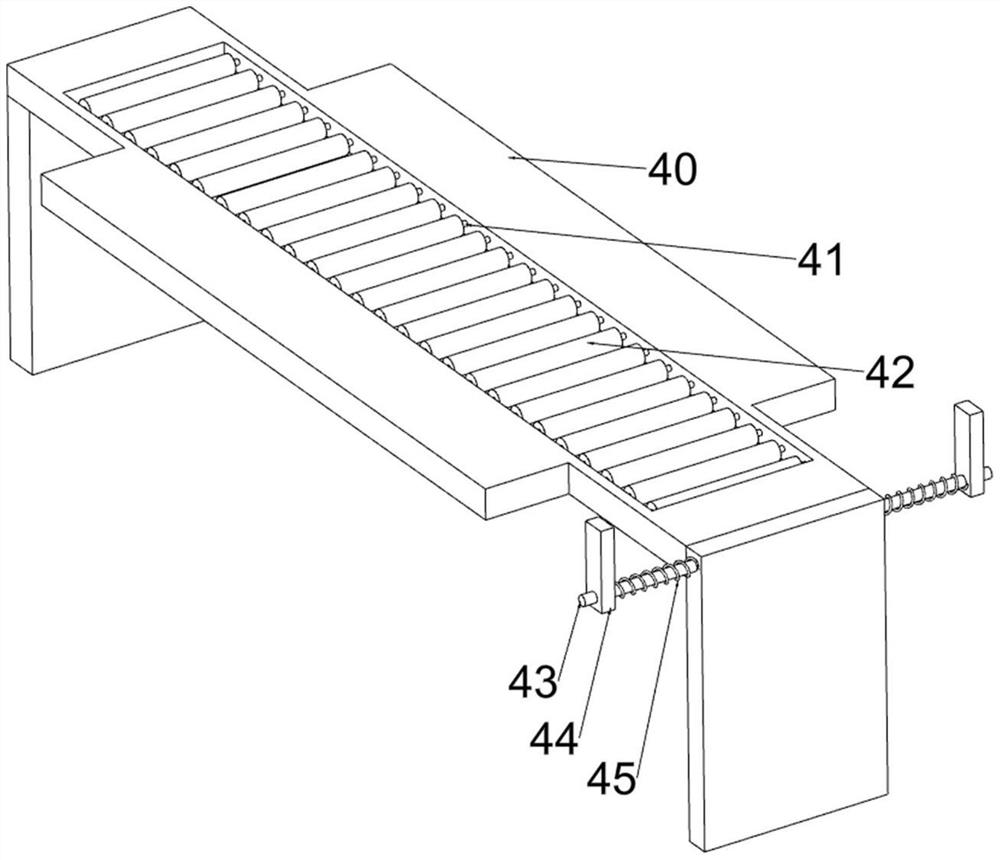

[0026] On the basis of Example 1, such as Figure 1-4 As shown, the placing mechanism 4 includes a placing frame 40, a first connecting rod 41, a first roller 42, a rotating rod 43, a block 44 and a torsion spring 45, and the left side of the top of the base 1 is provided with a placing frame 40. Evenly be provided with a plurality of first connecting rods 41, the first connecting rod 41 is connected with the first roller 42 in a rotating manner, the upper part of the right side of the placement frame 40 is connected with a rotating rod 43 in a rotating manner, and the two ends of the rotating rod 43 are connected with stoppers respectively. Block 44, torsion spring 45 is all connected between stop block 44 and placement frame 40, and torsion spring 45 is all sleeved on the rotating rod 43.

[0027] The worker puts the blackboard on the first roller 42. After polishing, when the worker pulls out the blackboard to the right, the first roller 42 will rotate, and the blackboard w...

Embodiment 3

[0035] On the basis of Example 2, such as figure 1 As shown, it also includes a placement basket 8, a storage basket 9, a handle 10 and a clamping switch 11. The right side of the base 1 top is provided with a placement basket 8, and the sliding type in the placement basket 8 is provided with a storage basket 9, and the right side of the storage basket 9 A handle 10 is provided, and locking switches 11 are arranged symmetrically front and rear on the right side of the placement basket 8 and the storage basket 9 .

[0036] The staff can place the storage basket 9 in the storage basket 8, and buckle the clamping switch 11 to fix the storage basket 9. The polished blackboard will fall into the storage basket 9. After all the blackboards are collected, they need to be taken out When storing the basket 9, open the locking switch 11, and then pull the handle 10 to pull out the storage basket 9, thereby collecting the polished blackboard.

[0037] Also include lifting plate 12 and s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap