Full-automatic filter plate processing production line

A production line and filter plate technology, applied in metal processing, etc., can solve problems such as low efficiency, hidden dangers to production safety, labor waste, and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

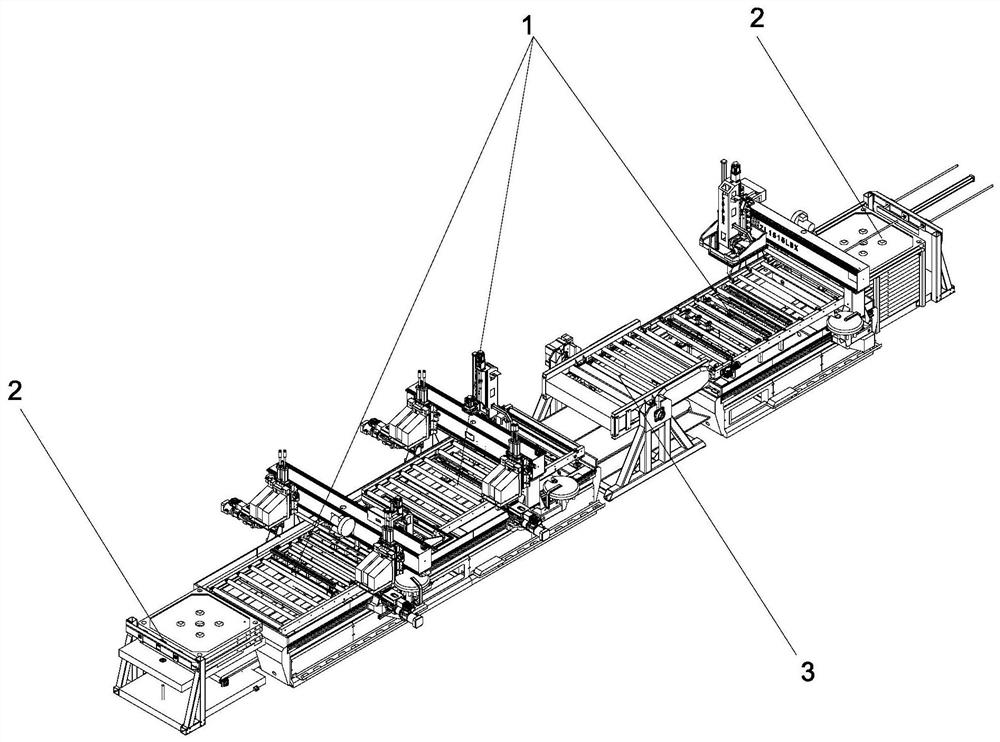

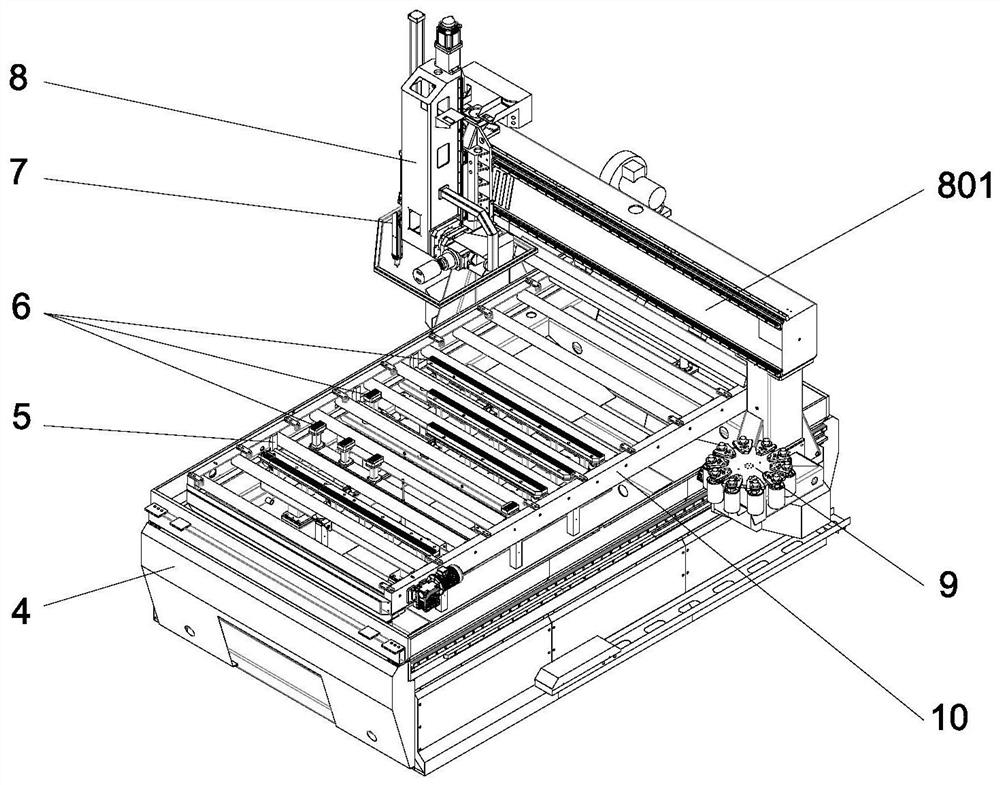

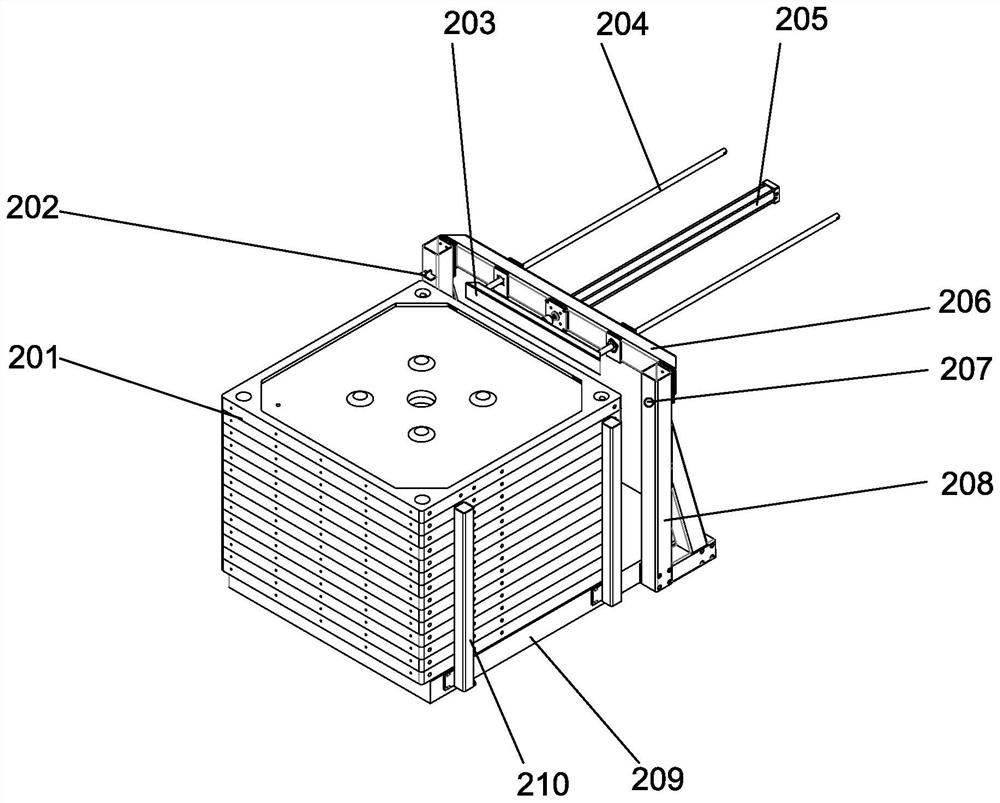

[0116] Such as figure 1 As shown, a filter plate processing production line includes several processing centers 1, and each processing center 1 includes a conveying mechanism 10 for conveying filter plate workpieces, an adsorption device 6 for fixing filter plate workpieces, a processing machine for processing Mechanism 8, a positioning device 5 for locating the position of the workpiece, a processing tool magazine 9 for storing processing tools, a workpiece measuring device 7 for measuring the size of the workpiece, a base 4 for installing and fixing each device, and a base for each The device controls the control device. There is also a turning mechanism 3 for changing the processing surface of the workpiece between the two machining centers. Depending on the process settings between adjacent machining centers, you can choose whether to set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com