Method for accurately positioning and quickly assembling dry-connection cantilever bent cap

A precise positioning and precise positioning technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., to achieve the effect of improving the matching degree of splicing surfaces, reducing the difficulty of manufacturing, and simplifying the temporary fixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

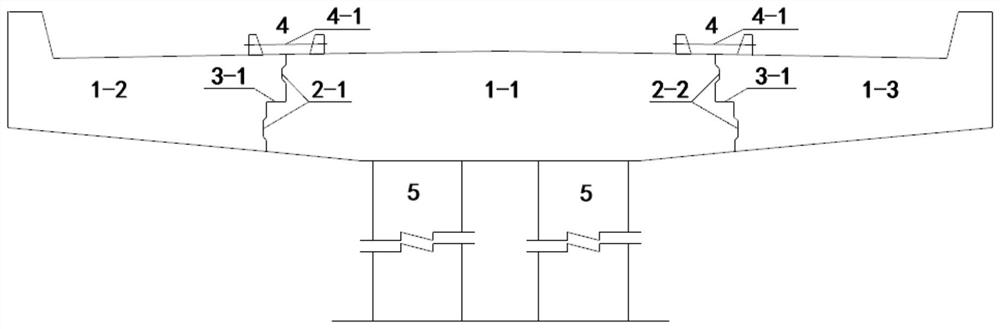

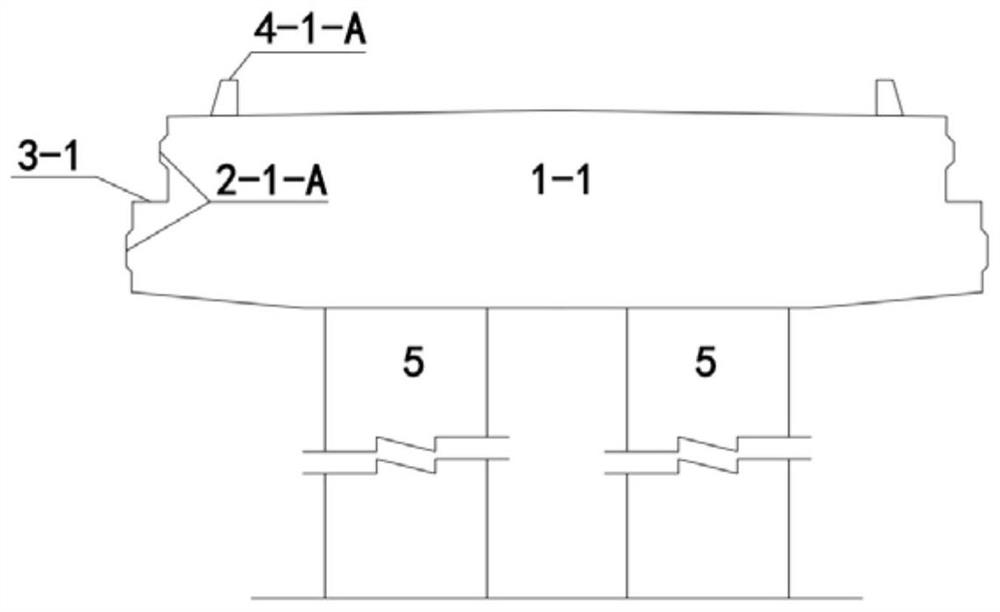

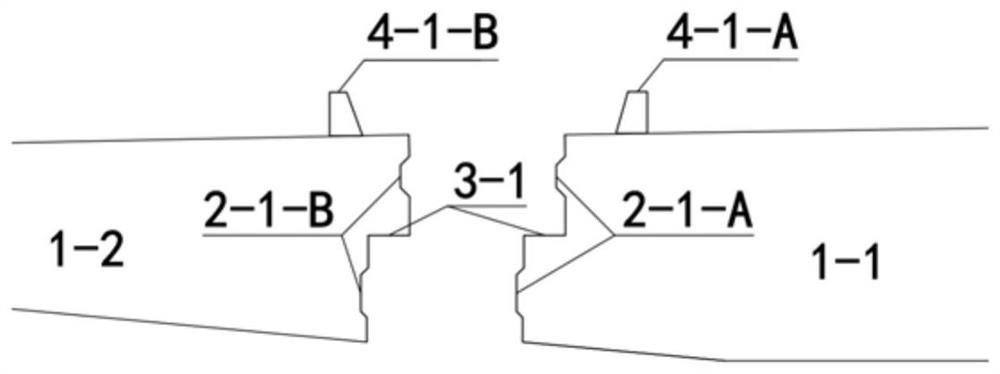

[0023] Such as Figure 1 to Figure 5 As shown, this embodiment specifically relates to a dry-joint cantilever cover beam precise positioning and rapid assembly method, which is used to hoist a large tonnage cover beam 9 on the top of the column 5; prefabricate a large cantilever cover beam 9 to the left Cantilever section cover beam 1-2, right cantilever section cover beam 1-3 and a middle section 1-1.

[0024] The method specifically includes the following steps:

[0025] (1) Pouring the middle cover beam 1-1; use the splicing surface A of the middle cover beam 1-1 as a formwork, and match the left cantilever section cover beam 1-2 and the right cantilever section cover beam 1-3 on both sides of the pouring , and then obtain the exact matching male-female matching left shear key 2-1, male-female matching right shear key 2-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com