Fish grass feeding device for aquaculture

An aquaculture, fish grass technology, applied in fish farming, circuit devices, battery circuit devices, etc., can solve the problems of labor consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

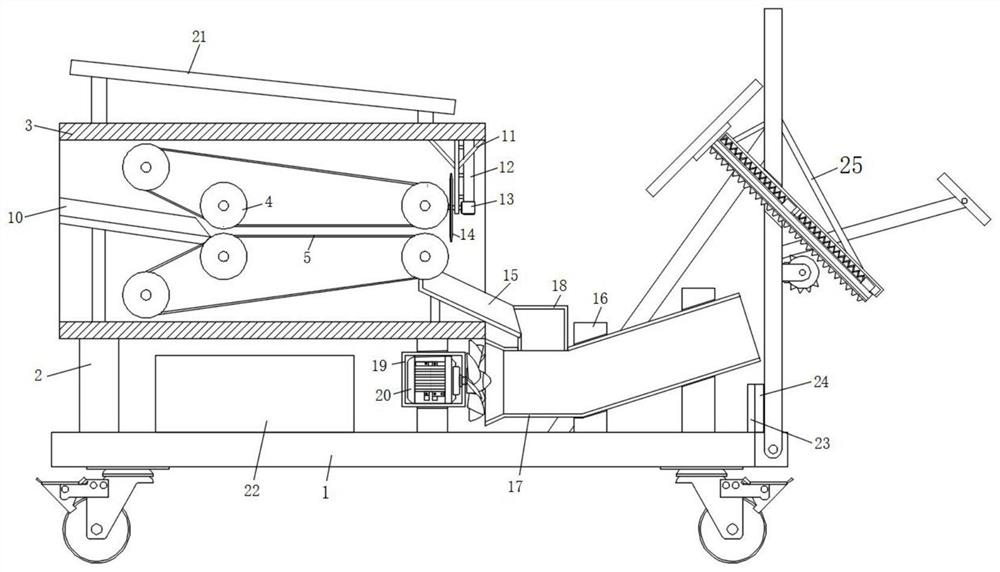

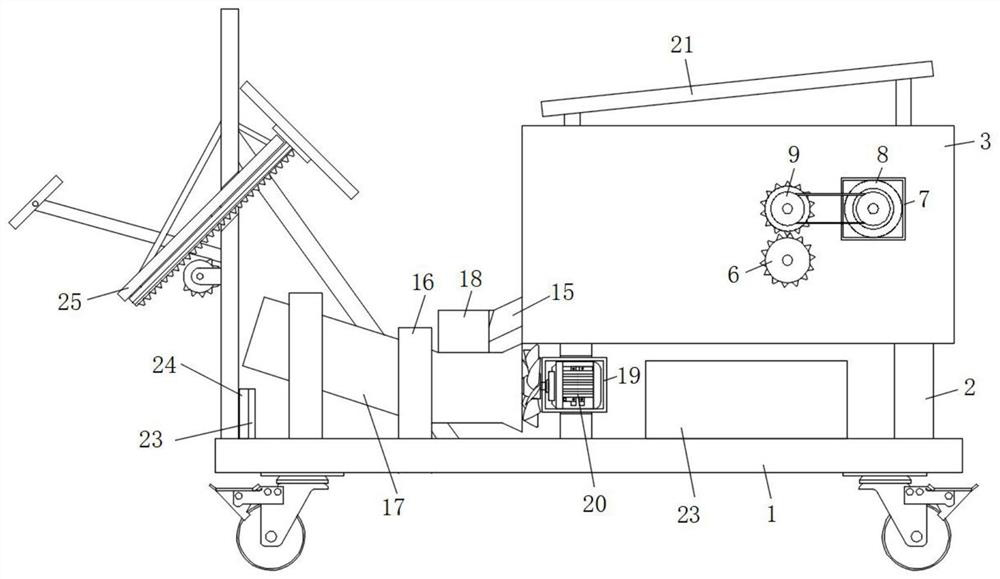

[0034] refer to Figure 1-7, a fish and grass feeding device for aquaculture, comprising a base 1, universal wheels are fixedly installed at the four corners of the bottom surface of the base 1, a fixed column 2 is welded on one side of the top surface of the base 1, and the top surface of the fixed column 2 is passed through a screw A crushing barrel 3 is fixedly connected, and the inner wall of the crushing barrel 3 is rotatably equipped with a pulley 4, and the three pulleys 4 in the same group are fixedly connected with a conveyor belt 5, and the two input ends of the conveyor belt 5 pass through the front side wall of the crushing barrel 3 And through the gear set 6 rotation connection, one side of the front end of the crushing bucket 3 is also fixed with a sealed box 7, the inner wall of the front end of the sealed box 7 is fixedly connected with a servo motor 8 by screws, and the output end of the servo motor 8 is connected to the The input end of one conveyor belt 5 is...

Embodiment 2

[0037] like Figure 4-7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the fixing assembly 2516 includes a fixing plate 2516a, the bottom surface of the fixing plate 2516a is fixedly connected with fixing pins 2516b, and a plurality of fixing pins 2516b are arranged and distributed in a matrix in the fixing plate 2516a bottom surface.

[0038] In this embodiment, the bottom end of the support rod 2515 is fixedly connected with a fixing component 2516, thereby facilitating the temporary fixing of the toggle mechanism 25, thereby ensuring a more stable operation of the toggle mechanism 25, and providing a certain guarantee for the stable feeding of fish and grass.

Embodiment 3

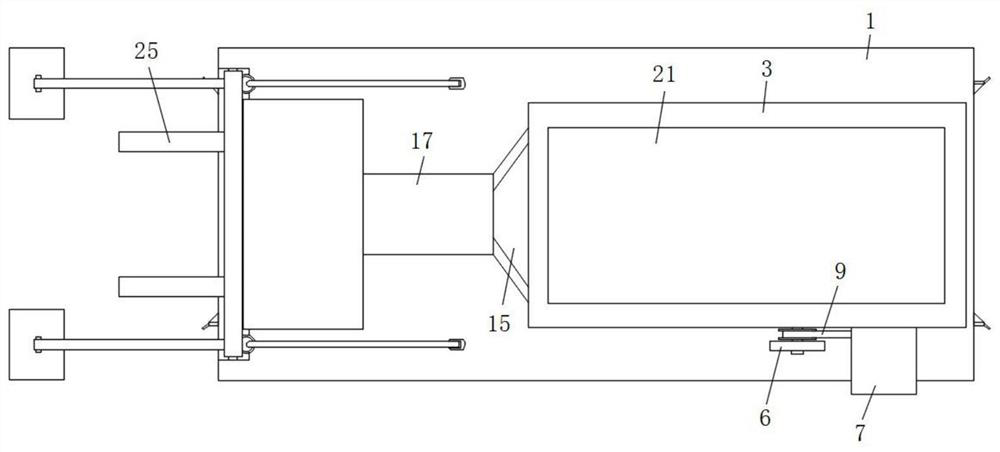

[0040] like Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the output end of the solar panel 21 is electrically connected to the input end of the battery pack 22, and the servo motor 1 8, the servo motor 2 13 and the biaxial motor 2510 The power supply ends are electrically connected to the output end of the battery pack 22 through wires.

[0041] In this embodiment, the solar panel 21 absorbs solar energy and stores it in the storage battery pack 22, so as to realize the collection of energy. The output end of the device is electrically connected, so as to meet the use of the device in remote areas, and greatly enhance the flexibility of the use of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com