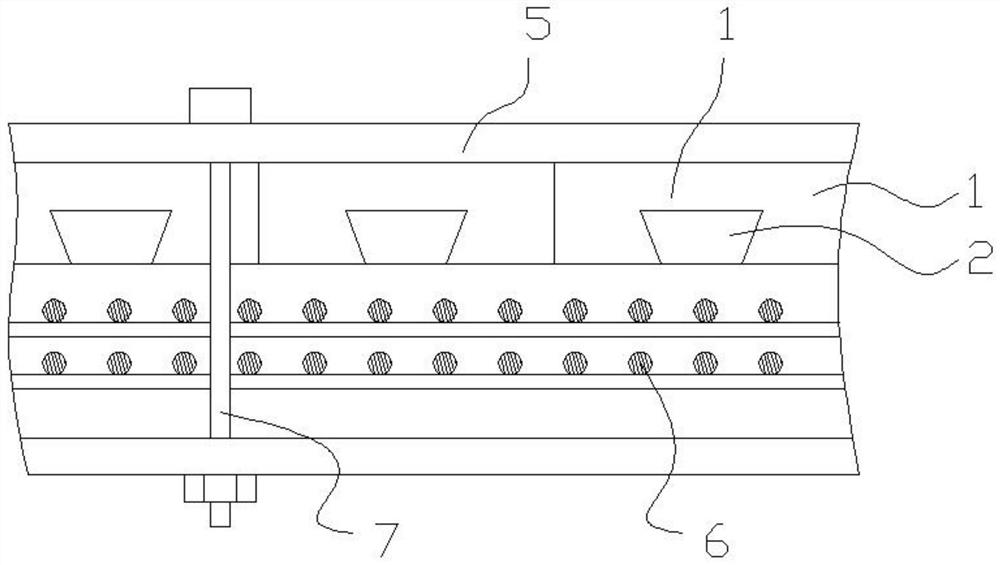

Integrated non-dismantling formwork and construction process thereof

A technology that avoids dismantling formwork and construction technology, applied in the field of building materials, can solve the problems of waste of materials and costs, heavy maintenance workload, and many hours of work, and achieve the effect of improved molding quality, good molding effect, and good integration strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0054] Such as Figure 9 , 10 As shown, in this embodiment, the end surface of the body is provided with preset fastening holes 4, and the preset fastening holes are provided with two left-right symmetrical ones. After the adjacent body templates are placed to prevent the pouring fluid from being impacted and misaligned, preset fastening holes are set on the end faces. When splicing, the impact strength needs to be met. Hole connection positioning, dislocation during placement and pouring process, to ensure connection performance and connection stability after forming.

Embodiment 3

[0056] Such as Figure 7 As shown, in this embodiment, the preset pouring groove is drop-shaped. Similarly, the drop-shaped inner groove body is set. During the pouring process, the groove is narrow and the groove bottom is wide. The poured fluid material enters the bottom of the groove for filling. Better stability.

Embodiment 4

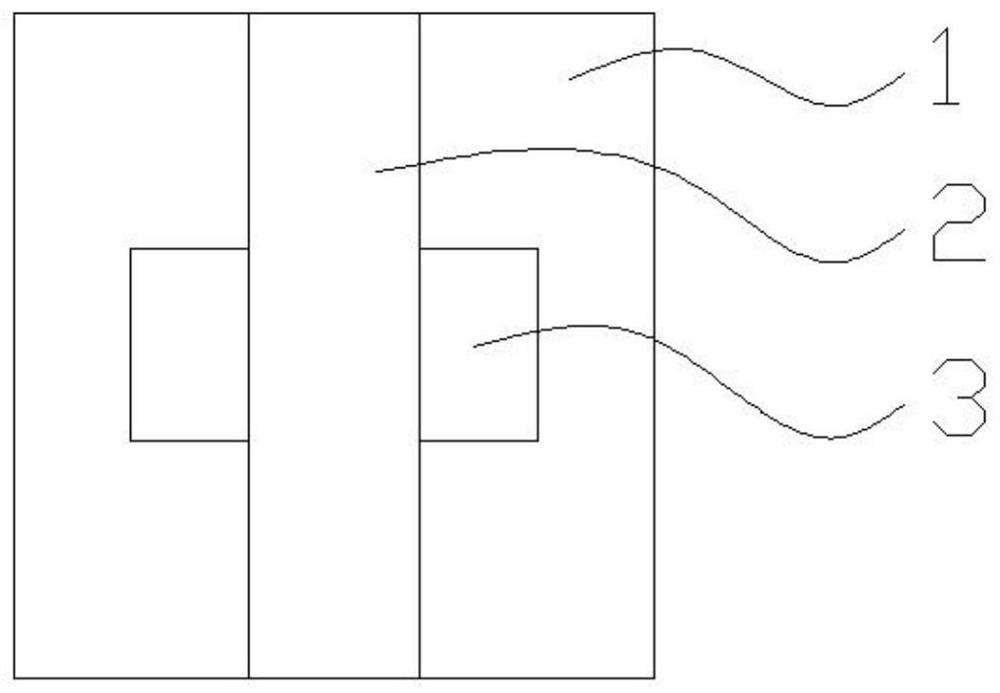

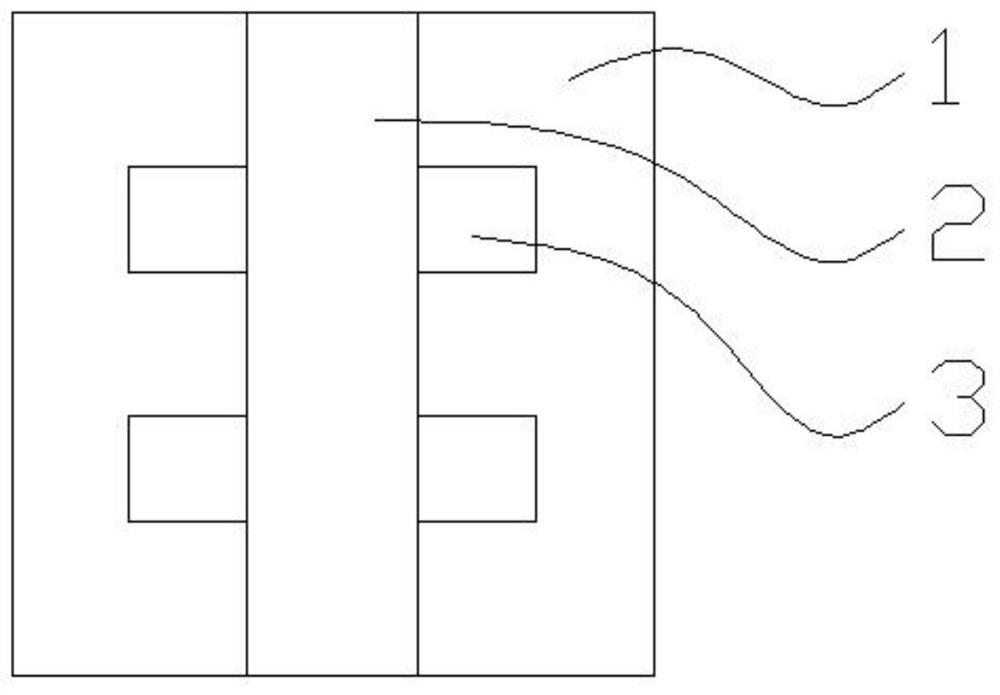

[0058] Such as image 3 As shown, in this embodiment, the lower end of the preset pouring trough is provided with transverse sags, and the sags are single-row or double-row rectangular troughs.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap