Reinforcing steel bar protective layer thickness control device and construction process

A steel bar protective layer and thickness control technology, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of wrong use of pads, difficulty in reaching the qualified rate of steel bar protective layer, and non-reusable use, so as to prevent falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

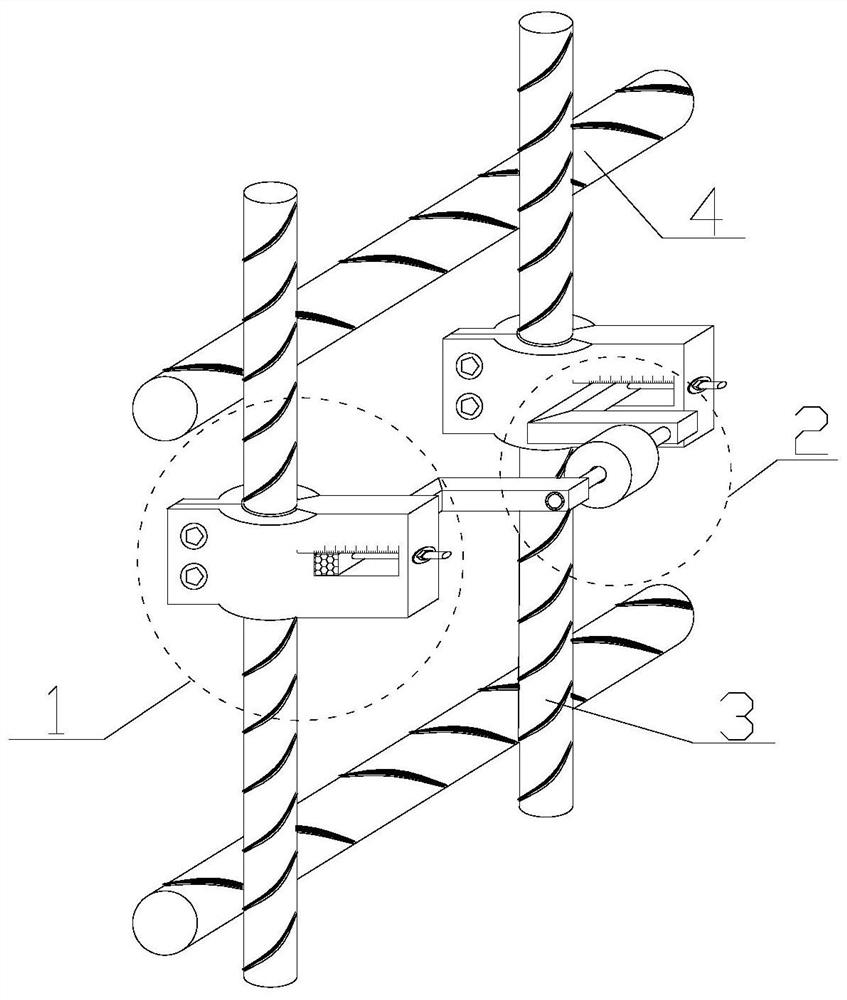

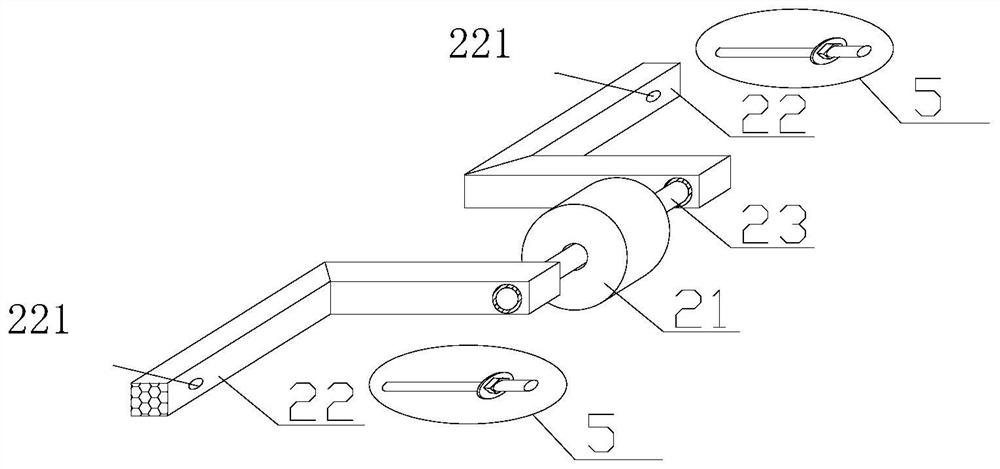

[0039] refer to Figure 1 to Figure 3 , a kind of control device for the thickness of steel bar protection layer, including vertical steel bar 3 and transverse steel bar 4, described vertical steel bar 3 and transverse steel bar 4 form a reinforcement cage, and described control device also comprises base point positioning part 1 and protective layer positioning part 2 , the base point positioning parts 1 are respectively fixed on two adjacent vertical steel bars 3 in pairs;

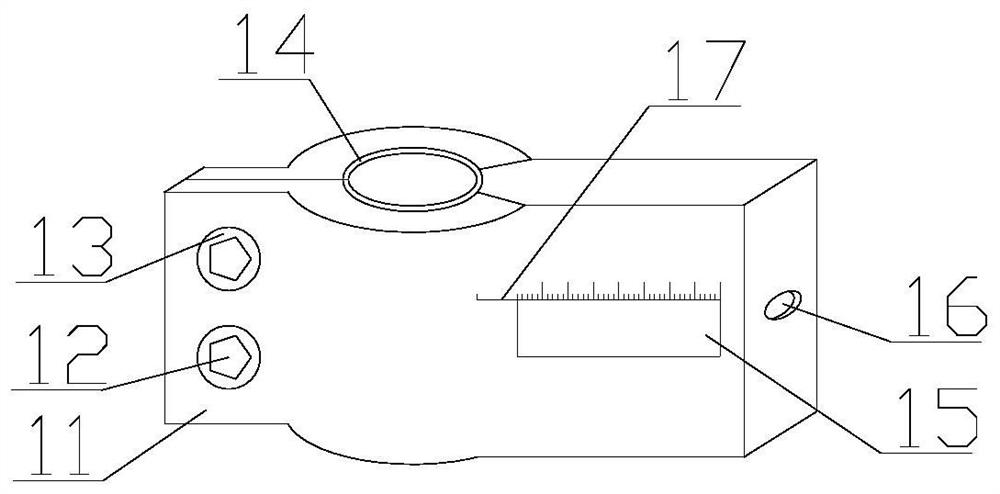

[0040] The base point positioning part 1 includes a clamp 11, a fastening bolt 12, a gasket 13, a fastening material 14, a limit movable hole 15, a limit hole 16 and a scale line 17, and one end of the clamp 11 passes through the fastening bolt. 12, the gasket 13 and the fastening material 14 are effectively connected to the vertical steel bar 3, the clamp 11 is provided with the limit movable h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com