Mechanical breaking demolition method for low-rise building

A construction and machinery technology, applied in the field of mechanized crushing and demolition of low-rise buildings, can solve problems such as difficulty in platform construction, save construction costs and labor costs, improve demolition efficiency, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

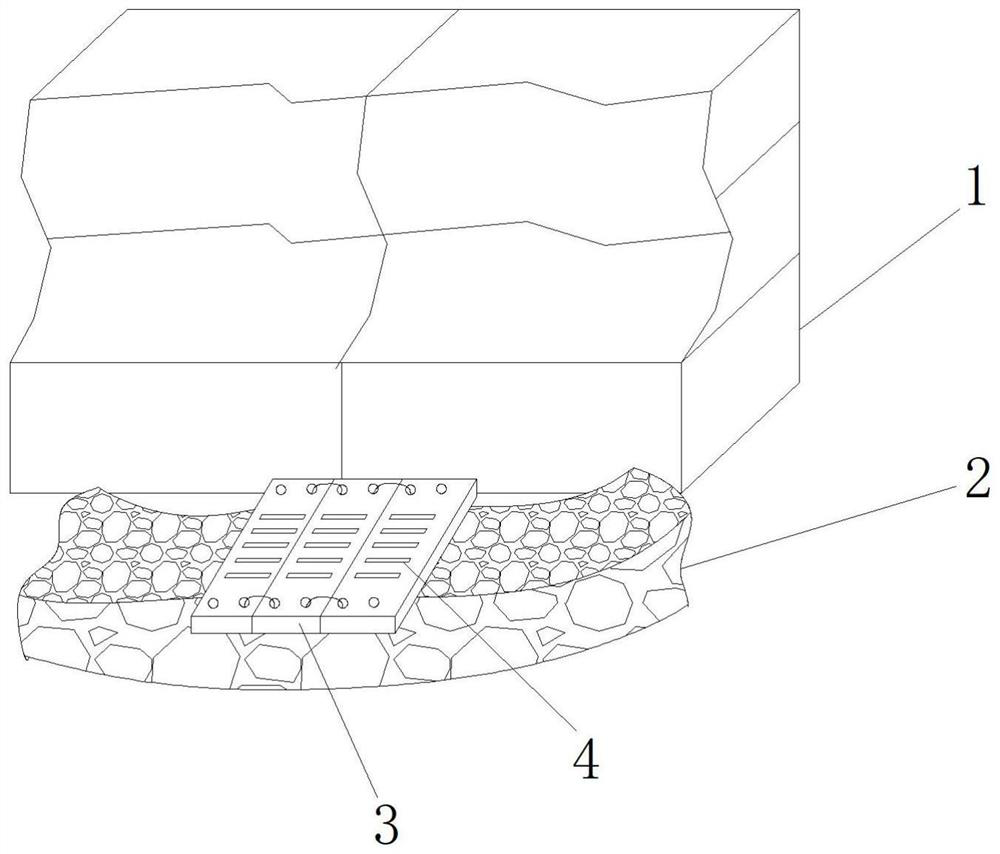

[0039] Embodiment one demolition single-family low-rise building

[0040] Taking the demolition of a high school library as an example, the construction method of the first embodiment will be described.

[0041] The building 1 has an area of 3150㎡ and is a 3-storey brick-concrete frame structure. The construction project is located in the bustling road section of the city, and the surrounding environment in the school is complicated, so it cannot be demolished by blasting; The construction efficiency of the division method is low, the construction cost is high, and the construction period is extremely tight, and manual demolition cannot meet the requirements; ordinary mechanized crushing and demolition requires the construction of a platform and the cooperation of large cranes, etc., resulting in increased workload and increased construction costs, and it is close to other teaching buildings. Unable to build platform. In order to save costs and reduce construction difficult...

Embodiment 2

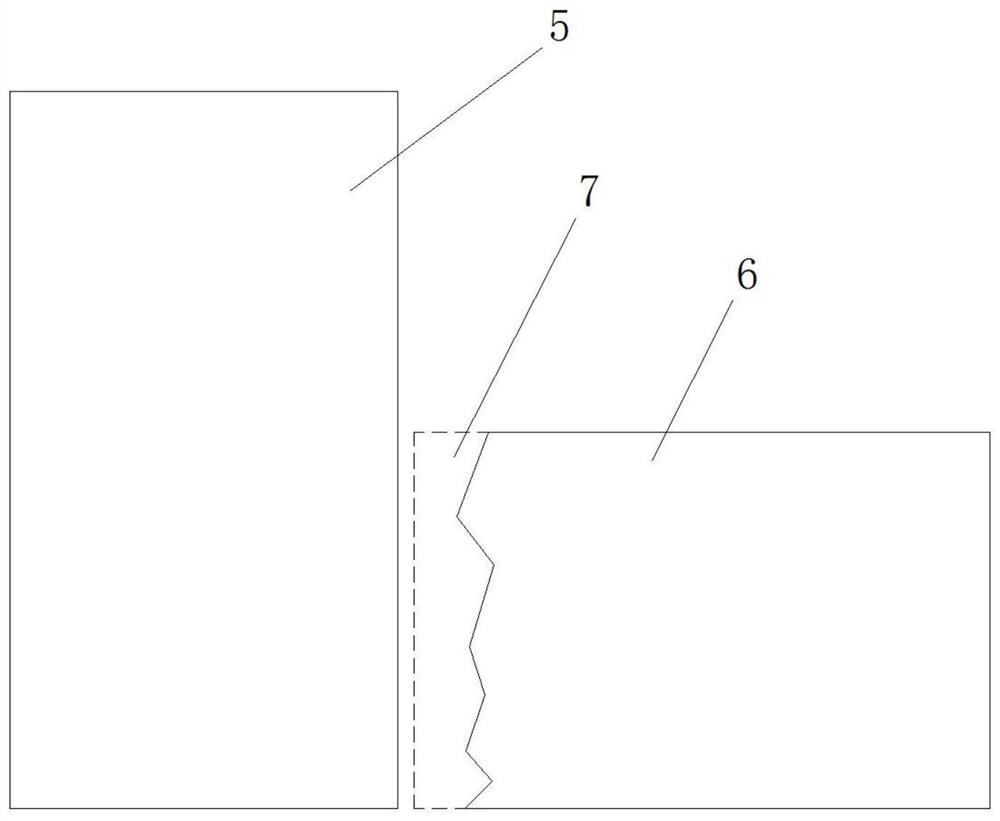

[0051] Embodiment two demolition of adjacent buildings

[0052] When demolishing one of the lower buildings 6 in the two adjacent buildings at an interval of 0-100cm, the above step (1) also includes the following steps before: adopting the long arm to remove the lower building 6 and the lower building 6 The adjacent surface of height 5 is cut from top to bottom, and the cutting width of the cutting part 7 is 1-2m. After the cutting is completed, use a long-arm excavator to peel off the remaining part of the adjacent surface on the higher building from top to bottom , and the remaining parts of the lower buildings are demolished as single-family buildings.

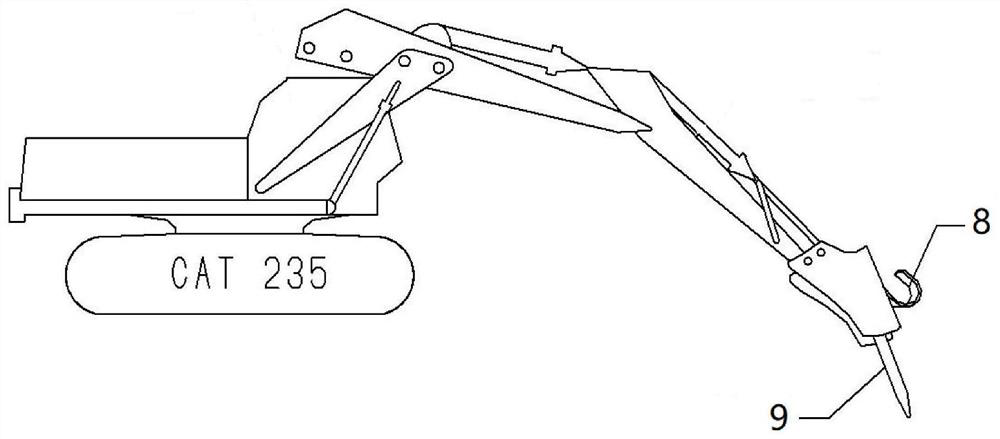

[0053] The invention utilizes the working platform built by the steel plate and the demolished building brick slag to reach any position of the building, so that the highest position of the building can also be dismantled; at the same time, a combination of long-arm excavator and ordinary excavator is adopted , which can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com