Monitoring method of state of gearbox bearing of wind turbine generator system

A technology for wind turbines and gearboxes, which is applied in the monitoring of wind turbines, wind turbines, engines, etc., can solve the problem of inability to realize real-time monitoring and diagnosis of gearbox bearings, early warning of abnormal temperature changes in gearbox bearings, and low modeling accuracy. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

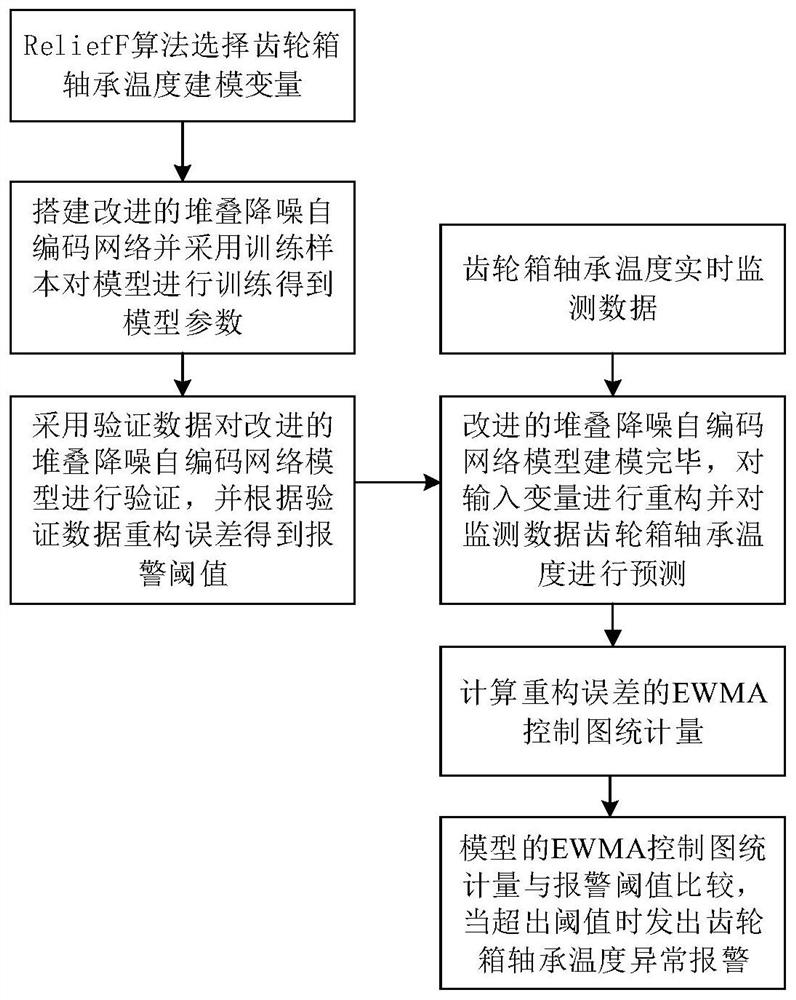

[0108] Taking the gearbox of a 2MW unit in a wind farm as the research object, the operation data recorded by the SCADA system at the level of 1 minute is selected, such as figure 1 As shown, in this embodiment, a method for monitoring the temperature state of a wind turbine gearbox bearing includes the following steps:

[0109] Step 1, set the feature weight threshold δ to 0.012, and select 12 variables that meet the requirements through the ReliefF algorithm, as shown in Table 1 below.

[0110] Table 1: Selection of variables for modeling gearbox bearing temperature

[0111]

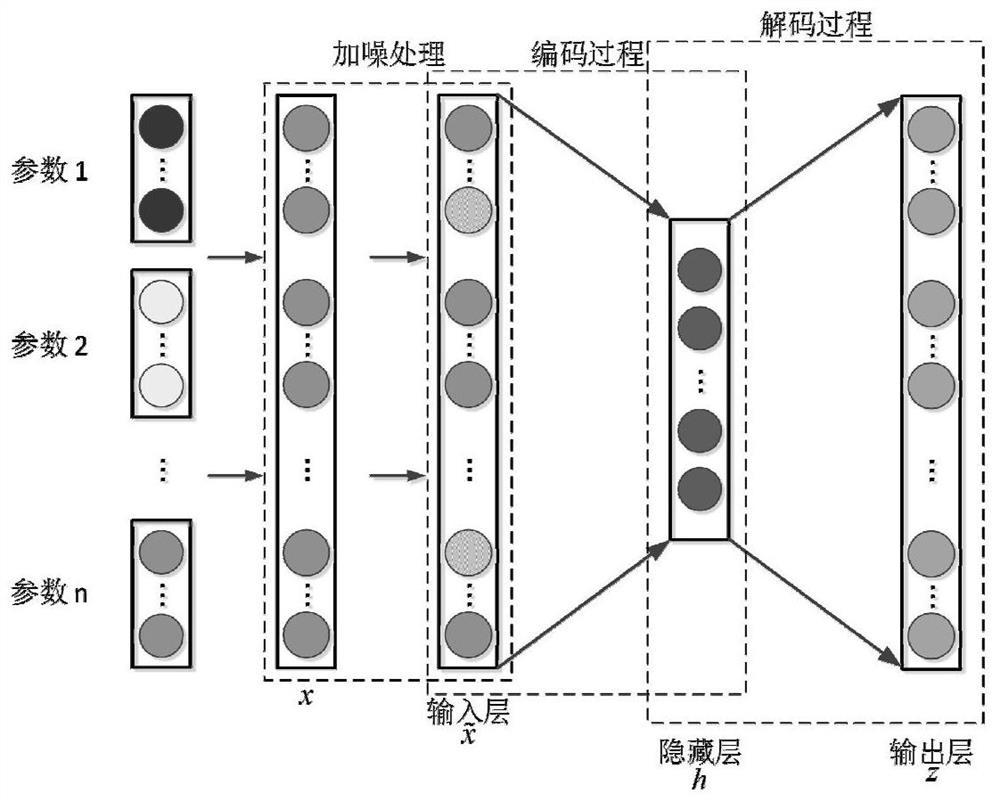

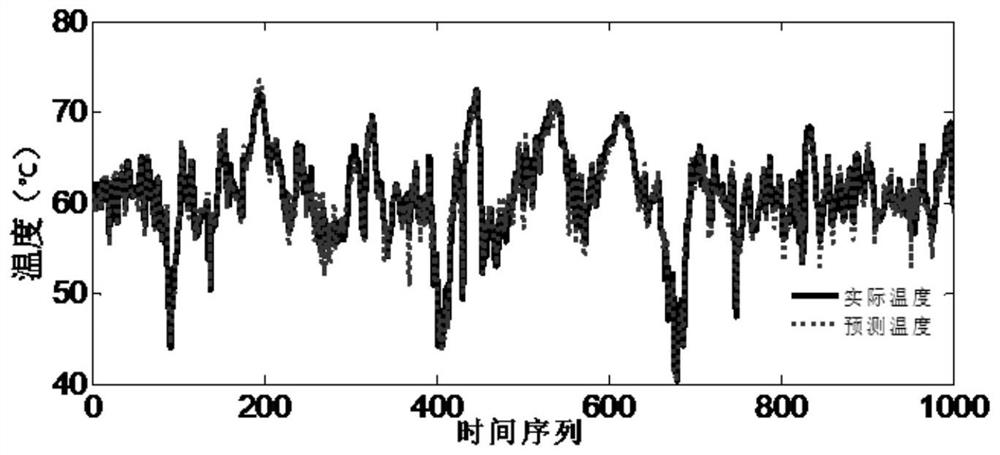

[0112] Step 2. Build an improved noise reduction autoencoder network model. The noise reduction autoencoder network structure is as follows: figure 2 As shown, the operating data of the unit from May to June was used as the training data set to train the model to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com