Swing mirror assembly, swing mirror assembly adjusting system and adjusting method

An assembly and adjustment method and component technology, which are applied in the directions of installation, optical components, optics, etc., can solve the problems of low production efficiency, poor stability, and reduce the pointing accuracy of the pendulum mirror, so as to simplify the structure design, reduce the difficulty of assembly and adjustment, and avoid pendulum. The effect of changing the mirror shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

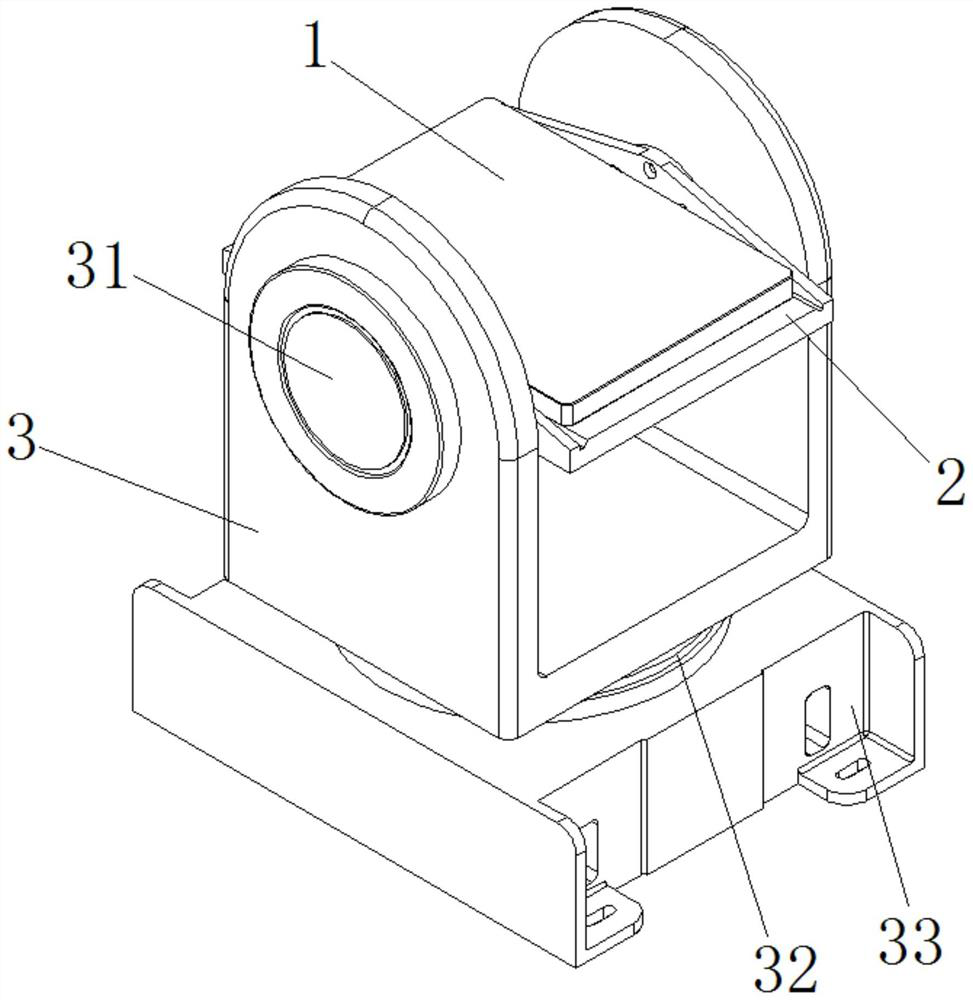

[0072] The pendulum mirror assembly provided by the invention is as figure 2 As shown, it includes an oscillating mirror 1 , an oscillating mirror base 2 and a two-axis system 3 , and the oscillating mirror base 2 can rotate relative to the horizontal axis 31 of the two-axis system.

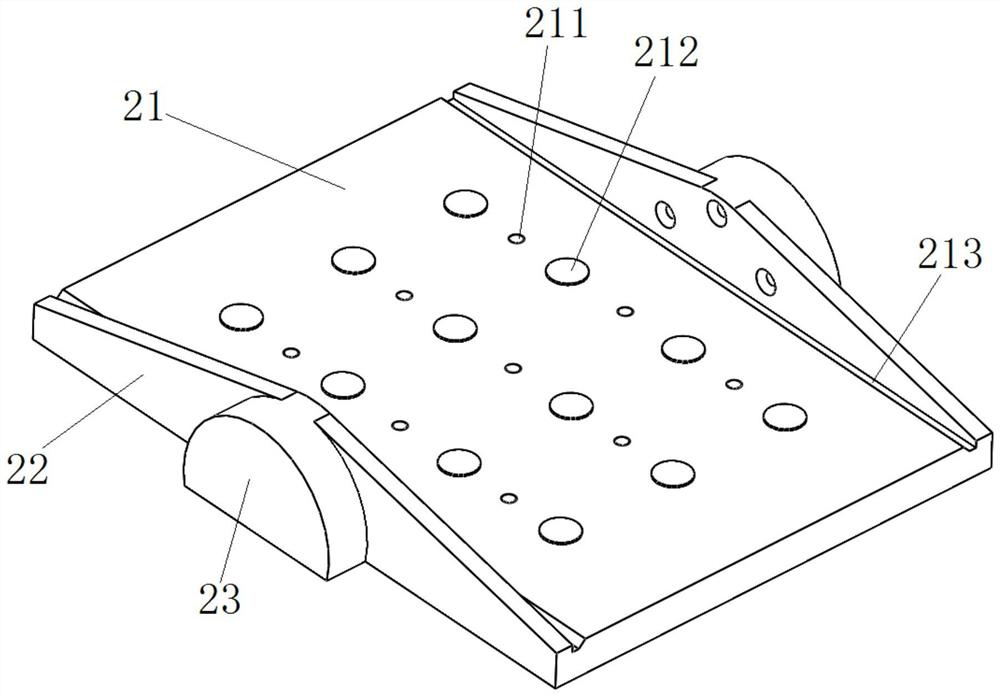

[0073] Oscillating mirror mirror holder 2 such as image 3 As shown, it includes a base 21, a plurality of top screw holes 211 and a plurality of adhesive bosses 212 arranged on the top surface of the base 21, support plates 22 respectively arranged on both sides of the base 21, and support plates 22 respectively arranged on both sides. The semicircular rotating shaft 23 of outer middle part. The plurality of screw holes 211 are arranged in multiple rows, and the plurality of gluing bosses 212 are arranged in multiple rows, and the rows of screw holes 211 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap