Wide-gap semiconductor substrate, apparatus for manufacturing wide-gap semiconductor substrate, and method for manufacturing wide-gap semiconductor substrate

A technology for manufacturing a device and a manufacturing method, which is applied in the field of wide energy gap semiconductor substrates, and can solve problems such as cracks, silicon substrate cracks, and gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0057] 1st embodiment

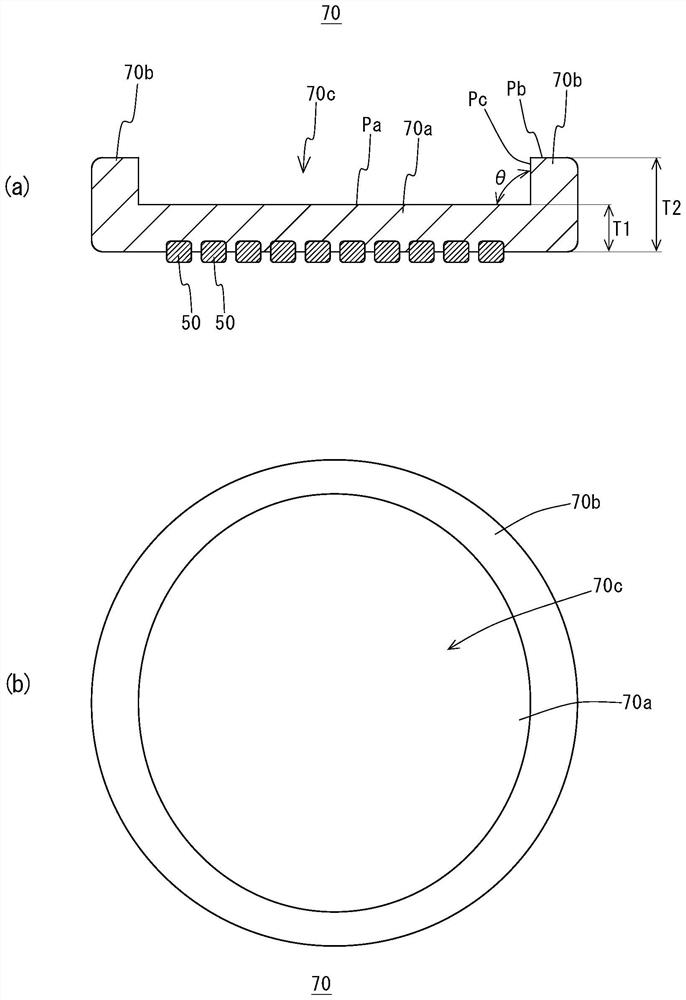

[0058] figure 1 (a) is a vertical sectional view of the semiconductor substrate 70 according to the first embodiment of the present invention, figure 1 (b) is a plan view of the semiconductor substrate 70 . The semiconductor substrate 70 is a wide-gap semiconductor substrate made of silicon carbide (4H-SiC) having high withstand voltage performance. Electronic components manufactured using the semiconductor substrate 70 have low power loss, and can be used as high-performance and power-saving inverter devices, power modules for home appliances, or power semiconductor components for electric vehicles.

[0059] In addition, compared with silicon, silicon carbide has a higher Young's modulus and a higher drop temperature even at high temperatures. Therefore, silicon carbide can be used as a MEMS (Micro-Electro Mechanical Systems) that has both ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com