Auxiliary device for replacing impeller bearing of wind turbine

An auxiliary device and wind motor technology, applied in the direction of workbench, manufacturing tools, etc., can solve problems such as unstable center of gravity, frequent accidents, etc., and achieve the effect of avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

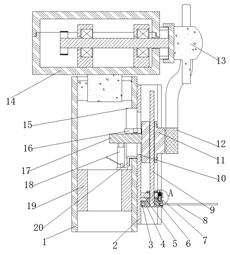

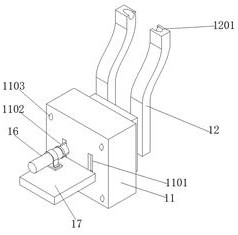

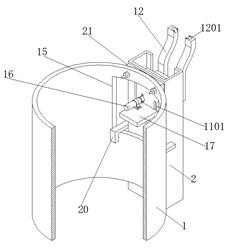

[0029] refer to Figure 1-5 , the wind turbine impeller bearing replacement auxiliary device, including the inner support tube 19 fixed on the inner wall of the support tower tube 1, and the chassis shell 14 that is rotatably connected to the top of the inner support tube 19, the middle of the chassis shell 14 is connected with a transmission shaft, and the transmission The end of the shaft is sleeved with an impeller head 13, a C-shaped steel column 2, and a T-shaped slider 11 is slidably connected in the chute of the C-shaped steel column 2. There is a window 15, and two parallel rectangular sockets 1101 are opened on the side of the T-shaped slider 11 far away from the bottom of the groove, and the two sockets 1101 are inserted with a board 1204, and the two boards 1204 are far away from the support tower One end of the pipe 1 is fixed with a U-shaped support rod 12, and a single support rod of the U-shaped support rod 12 is arranged in a Z-shaped structure, and the top of ...

Embodiment 2

[0039] refer to figure 1 and Figure 5 , wind turbine impeller bearing replacement auxiliary device, compared with embodiment 1, this embodiment also includes an annular groove on the upper surface of the turntable 4 near the peripheral edge, and a non-return tooth 703 is arranged in the annular groove, and the fixed plate 5 There is a mounting hole on the upper surface of the mounting hole, and an opening downward positioning barrel 7 is clamped in the mounting hole. The bottom opening of the positioning barrel 7 is slidably connected with an inner sliding rod 702, and the bottom end of the inner sliding rod 702 is provided with a triangular anti-skid Back-moving spring 701 is fixed between the top of the inner slide bar 702 and the bottom of the barrel.

[0040] Wherein, the top of the inner sliding rod 702 is fixed with a pull rod, and the top of the pull rod is fixed with a pull ring, so that it can be locked at any time when the transmission screw 9 rotates during use, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com