Vehicle threshold mounting method and vehicle threshold structure

An installation method and vehicle technology, applied in the field of automobile body-in-white, can solve problems such as poor door sealing and thresholds that cannot meet the accuracy of the door seam surface, and achieve the effects of enhanced strength and anti-collision performance, simple and quick installation method, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

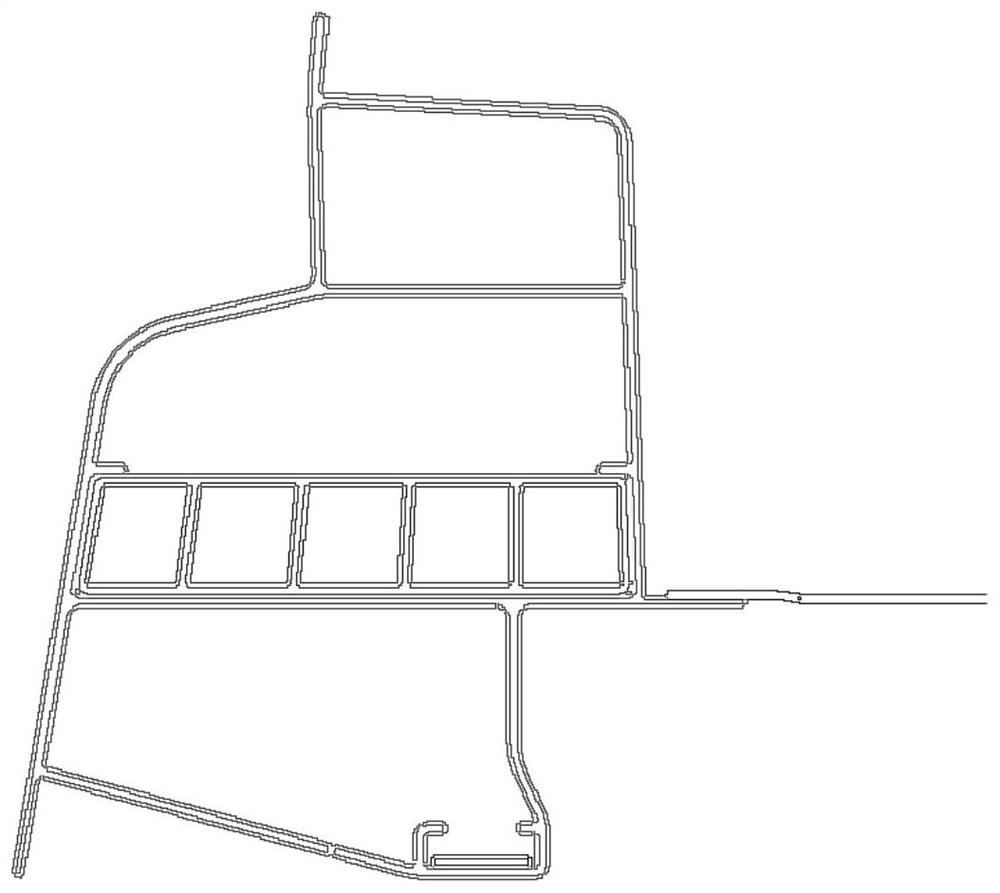

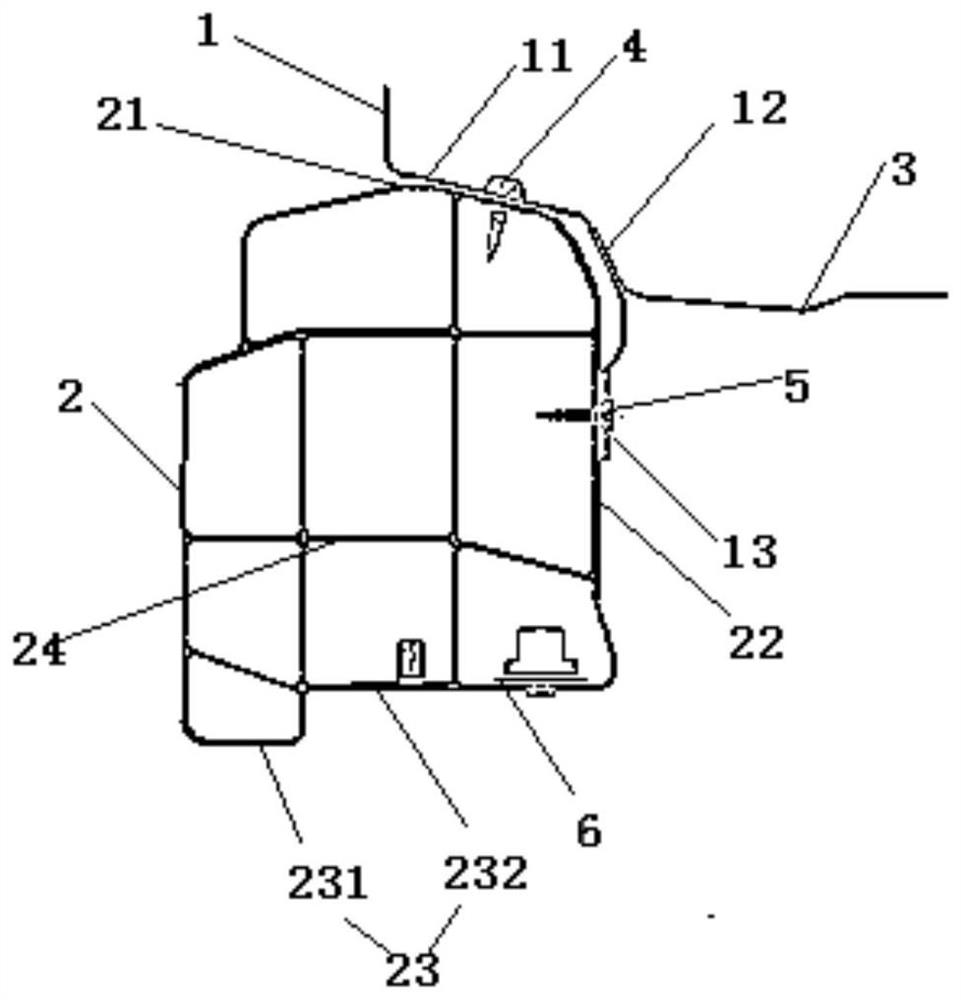

[0032] In this embodiment, a method for installing a vehicle door sill is provided, including the following steps:

[0033] S1. Provide a sill inner panel 1. The sill inner panel 1 is a steel sheet metal part provided with an upper section 11, a middle section 12 and a lower section 13. The middle section 12 is formed between the upper section 11 and the lower section 13. The middle section 12 and the body floor 3 pass through points Connected by welding to form the skeleton structure of the vehicle body;

[0034] S2. Provide a threshold outer panel 2, the threshold outer panel 2 is installed along the lateral direction of the vehicle, and the top wall 21 of the threshold outer panel 2 is fixedly connected to the upper section 11;

[0035] S3. The side wall 22 of the sill outer panel 2 close to the sill inner panel 1 is fixedly connected with the lower section 13 .

[0036] In the installation method of the vehicle door sill in this embodiment, the steel plate door sill inner...

Embodiment 2

[0043] In this embodiment, continue to refer to figure 2 , provides a vehicle threshold structure, the vehicle threshold structure adopts the installation method of the above-mentioned embodiment to be installed on the vehicle body, including the threshold inner panel 1 and the threshold outer panel 2 of aluminum profiles; the threshold inner panel 1 is a steel sheet metal part, and the threshold inner panel Panel 1 is provided with upper section 11, middle section 12 and lower section 13, middle section 12 is formed between upper section 11 and lower section 13; It is fixedly connected with the side wall 22 of the threshold outer panel 2 close to the threshold inner panel 1 . In the vehicle threshold structure in this embodiment, the threshold inner panel 1 is an integrally formed steel sheet metal part, and the position of the door opening adopts the steel threshold inner panel, which is fixedly connected with the vehicle body floor 3 to form a vehicle body skeleton structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com