An intelligent storage protection method and system for tilt angle detection

A technology of intelligent warehousing and tilting angle, which is applied in the direction of measuring angle, measuring device, surveying and navigation, etc., can solve the problems of automatic logistics warehousing loss, collapse, affecting the storage of goods, etc., and achieve the effect of avoiding personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

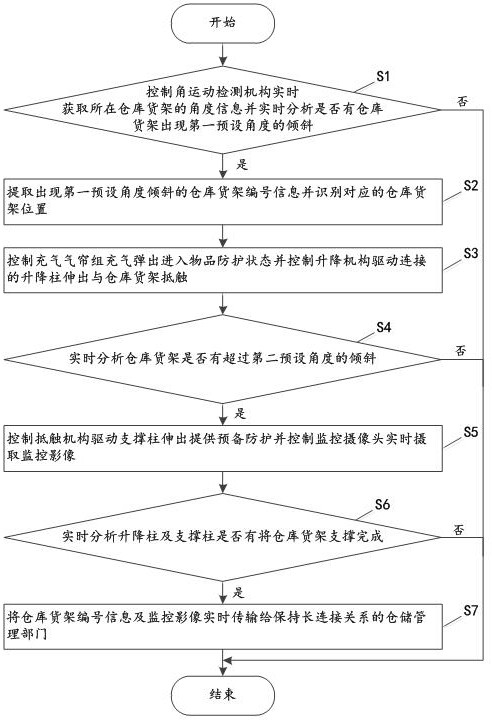

[0070] refer to Figure 1-2 , Figure 6-7 shown.

[0071] This embodiment provides an intelligent warehouse protection method for tilt angle detection, and the method includes the following steps:

[0072] In S1, specifically after the information receiving module 31 included in the warehouse controller 3 receives the protection instruction sent by the warehouse management department, the angle detection module 32 included in the warehouse controller 3 controls the angular motion detection mechanism disposed at the warehouse shelf position 10. Start to obtain the angle information of the warehouse shelf in real time, and the information analysis module 33 included in the warehouse controller 3 analyzes in real time whether there is a warehouse shelf that tilts at the first preset angle according to the angle information obtained in real time by the angular motion detection mechanism 10. , wherein the first preset angle of inclination is set by the warehouse management depart...

Embodiment 2

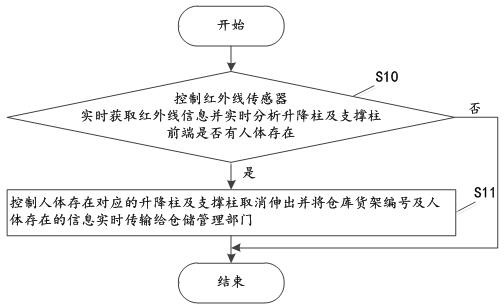

[0083] refer to image 3 , Figure 6-8 shown.

[0084] Specifically, this embodiment is basically the same as the first embodiment, the difference is that in this embodiment, after S2, the method further includes the following steps:

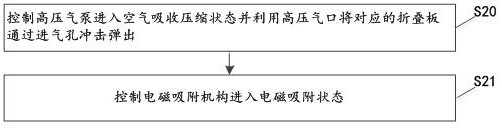

[0085] In S20, after the information analysis module 33 has identified and completed the corresponding warehouse shelf position and all the bound institutional information, the high voltage control module 41 included in the warehouse controller 3 controls and is arranged inside each storage layer of the warehouse shelf The high-pressure air pump 20 at the position starts to enter the air absorption and compression state, and then the high-pressure control module 41 controls the high-pressure air pump 20 to use the high-pressure air port 21 to impact the air into the air inlet of the folding board 22, and then uses the impact force of the air to compress the folding board 22. pops out, so that the top end of the folded plate 22 abuts the top en...

Embodiment 3

[0088] refer to Figure 4-6 , Figure 9 shown.

[0089] Specifically, this embodiment is basically the same as the second embodiment, the difference is that, in this embodiment, after S6, the method further includes the following steps:

[0090]In S60, specifically after the information analysis module 33 analyzes that the lift column 13 and the support column 15 have not completed supporting the warehouse shelves, the movement control module 43 included in the warehouse controller 3 controls the location outside the warehouse. The protective mobile shell group 24 is activated. After the protective mobile shell group 24 is activated, the movement control module 43 controls the protective mobile shell group 24 to move to the warehouse shelf position according to the monitoring image, and moves to Collapsed warehouse shelf location.

[0091] In S61 , specifically after the moving guard moving casing is moved to the warehouse shelf position, the magnetic interference module 47...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com