Mass concrete pouring cooling construction method for amusement project

A large-volume concrete and construction method technology, which is applied in the direction of construction, building structure, and basic structure engineering, can solve the problems of inconvenient concrete loss of heat, reduce heat of hydration, and unsatisfactory cooling effect of concrete, so as to reduce concrete cracks, Reduce heat of hydration and reduce temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

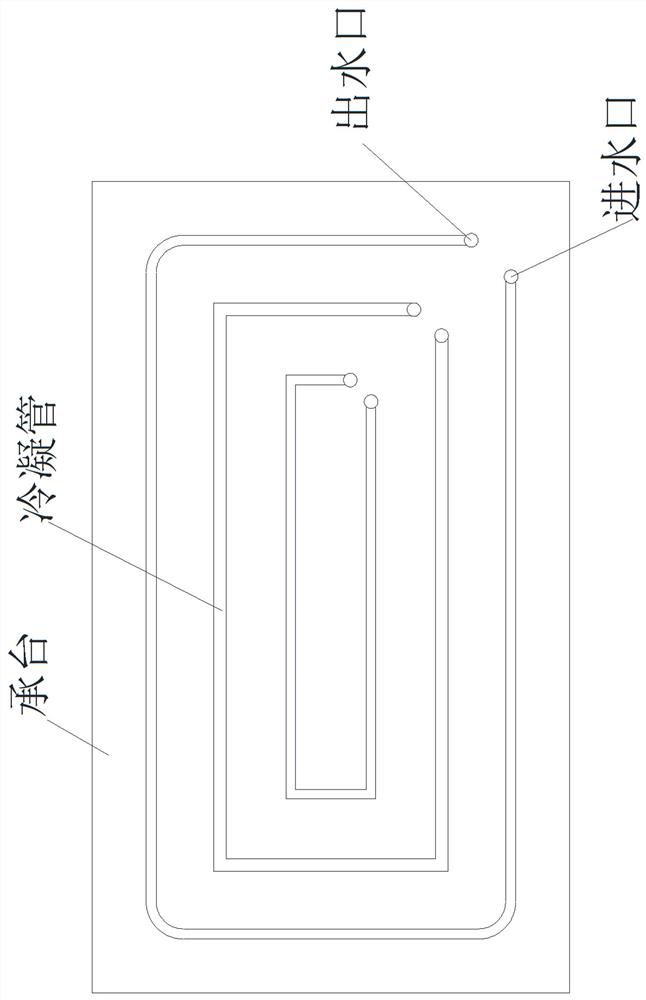

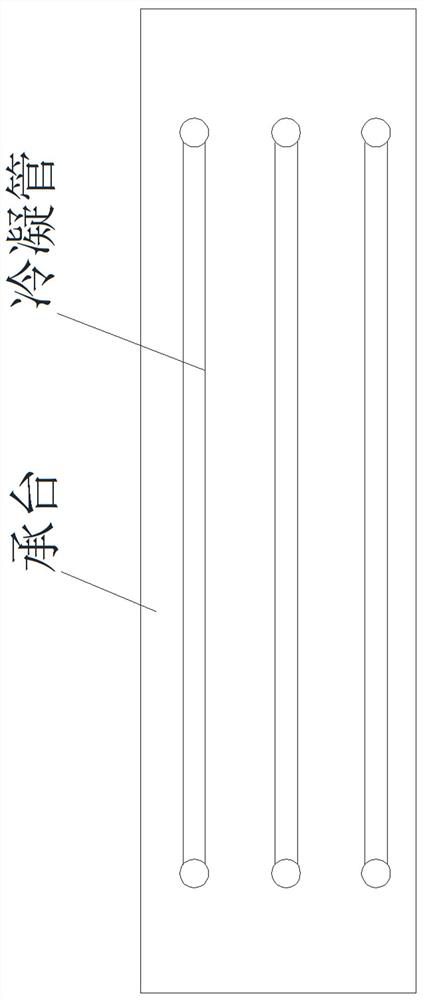

[0017] Such as figure 1 with figure 2 As shown, a large-volume concrete pouring and cooling construction method for amusement projects includes the following steps: Step a. Laying of condensation pipes: according to the size of the cap, a plurality of condensation pipe planes are sequentially arranged on the cap from top to bottom. Layer unit, condensing tube The plane layer unit includes multiple rectangular condensing tubes, the central axes of the plane composed of multiple rectangular condensing tubes coincide, and the area of the plane composed of multiple rectangular condensing tubes increases sequentially from the inside to the outside. Two adjacent rectangular condensing tubes The distance between them is 2m, and the distance between the rectangular condensation pipe on the outer edge and the edge of the platform is 1.5m; the condensation pipe adopts a GDJ iron pipe with an inner diameter of φ32mm and a wall thickness of 1.5mm. The end of the condensation pipe is ta...

Embodiment 2

[0022] Such as figure 1 with figure 2 As shown, a large-volume concrete pouring and cooling construction method for amusement projects includes the following steps: Step a. Laying of condensation pipes: according to the size of the cap, a plurality of condensation pipes are sequentially arranged on the cap from top to bottom Plane layer unit, condensing pipe The plane layer unit includes multiple rectangular condensing pipes. The central axes of the plane composed of multiple rectangular condensing pipes coincide, and the plane area composed of multiple rectangular condensing pipes increases sequentially from inside to outside. The distance between the tubes is 2.2m, and the distance between the rectangular condensation tube on the outer edge and the edge of the platform is 2m; the condensation tube adopts a GDJ iron tube with an inner diameter of φ32mm and a wall thickness of 1.5mm. The pipe joint and the straight pipe joint form a rectangular condensation pipe. The corner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com