Prefabricated bathroom and kitchen floor, mounting structure, and construction method

A construction method and floor slab technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of long construction period, prolonged construction period, high construction noise, etc., so as to shorten the on-site construction period, accelerate the construction progress, and have high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

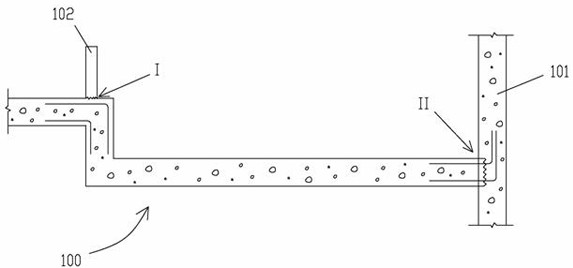

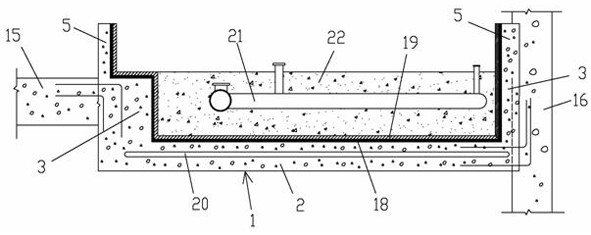

[0036] According to an object of the present invention, a prefabricated bathroom and kitchen floor is provided, figure 2 A cross-sectional view of the installation structure of the prefabricated bathroom and kitchen floor slab is schematically shown according to an embodiment of the present invention.

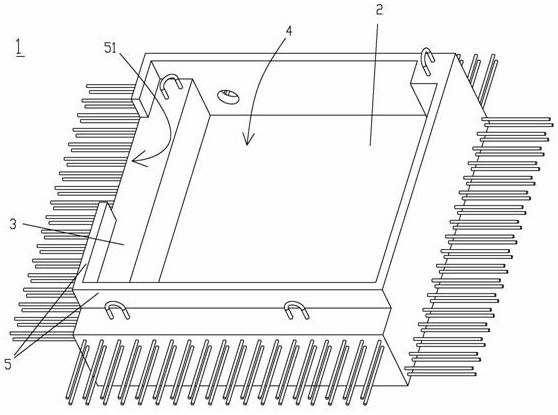

[0037] Please refer to figure 2, a prefabricated bathroom and kitchen floor. The prefabricated floor 1 as the main body of the prefabricated bathroom and kitchen floor is formed by one-time pouring of concrete. The prefabricated floor 1 includes a bottom slab 2 and a side wall 3 perpendicular to the bottom slab 1 and extending upward. The bottom slab 2 and the side wall 3 A groove 4 with an upward opening is formed, and the top surface of the side wall 3 is provided with a vertically upwardly extending low wall 5 formed by pouring. The inner walls of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com