Dark tea flower drying drying room and control method for black tea flower drying

A technology for flower drying and black tea, which is applied in drying room/container, drying solid materials, drying goods processing, etc., can solve the problems of miscellaneous bacteria, less flower blooming and no flower blooming in tea base, and achieve industrial production effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

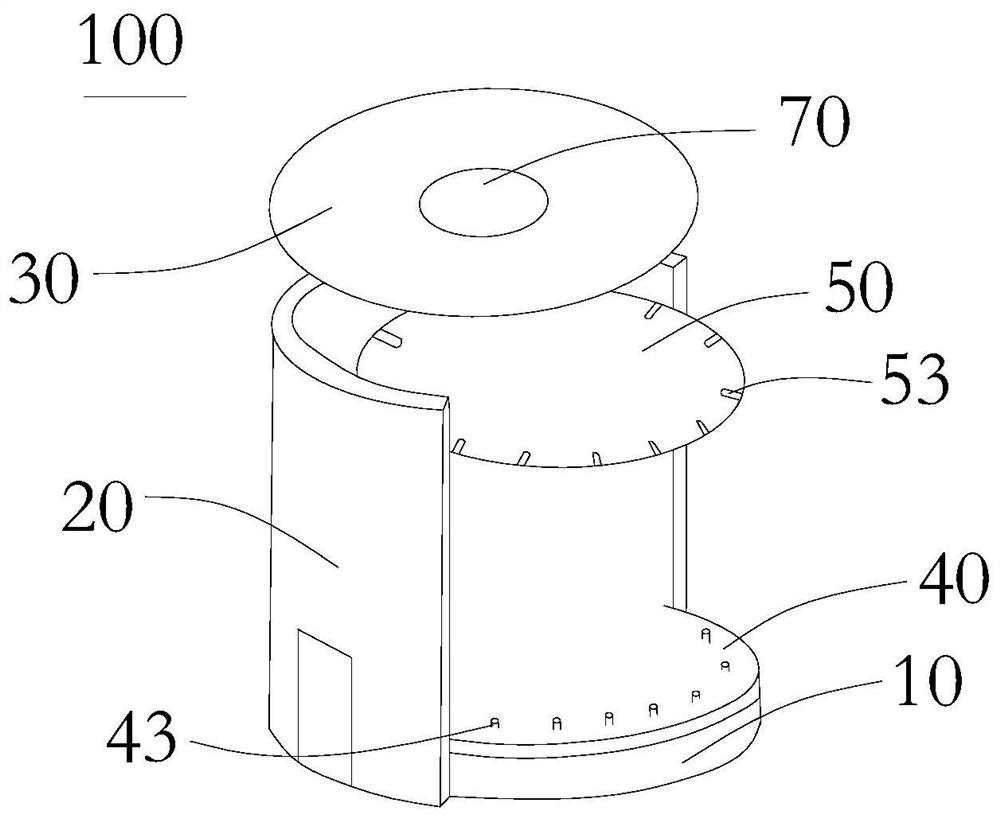

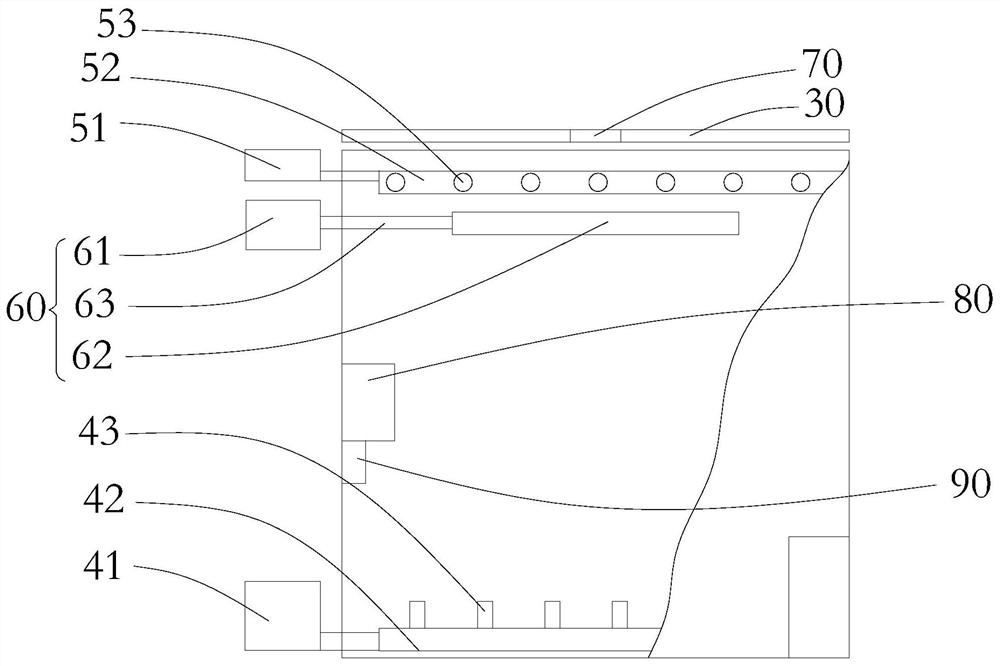

[0025] figure 1 It is a schematic diagram of a partial three-dimensional structure of the drying room 100 for drying black tea flowers in a preferred embodiment of the present invention; figure 2 It is a structural schematic diagram of a dark tea flower drying oven 100 in a preferred embodiment of the present invention.

[0026] Such as figure 1 and figure 2 As shown, the black tea flower drying room 100 of the present embodiment includes a base plate 10, a wall 20 arranged on the base plate 10 along a direction perpendicular to the surface of the base plate 10, and a wall 20 arranged on the top of the wall 20 for sealing the wall. The top plate 30 of the top opening of the body 20, the wall body 20 is circular, and the bottom plate 10, the wall body 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com