Unsupervised industrial product defect detection method and device based on deep learning

A defect detection and deep learning technology, applied in image data processing, instrumentation, computing, etc., can solve problems such as poor defect detection effect, and achieve the effect of solving poor defect detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

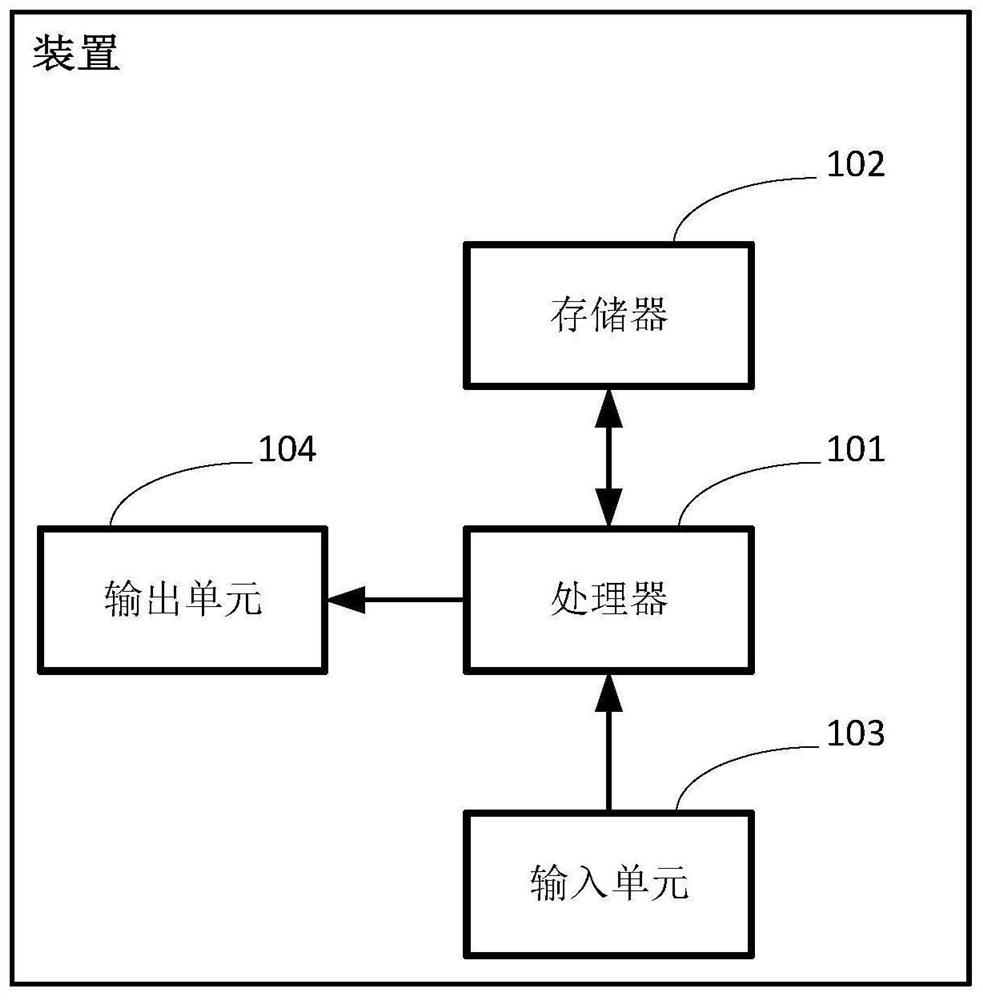

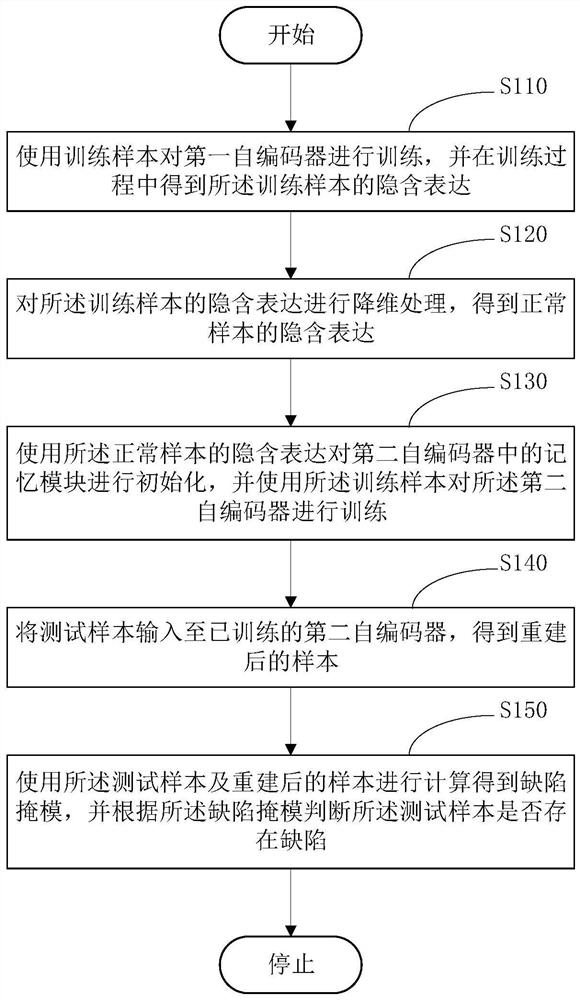

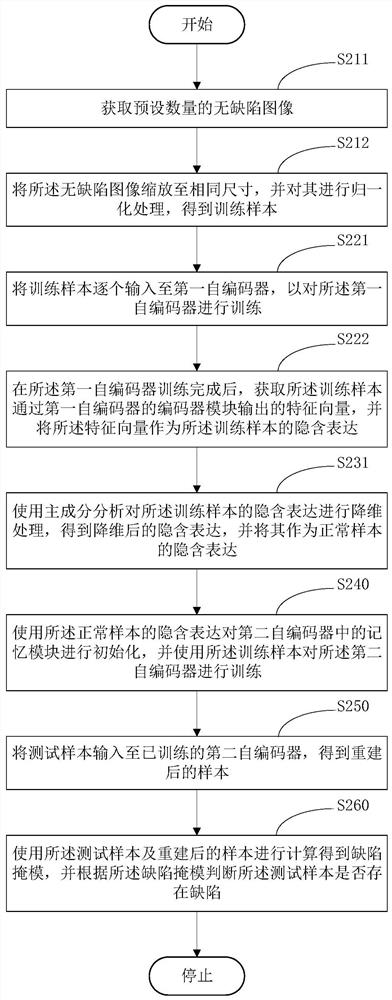

[0038] In order to solve the problem that the defect detection effect of the traditional technology is poor due to the difficulty in obtaining defective image samples, the present application uses training samples to train the first autoencoder, and obtains the implicit value of the training samples during the training process. expression; wherein, the training sample is a defect-free image; the hidden expression of the training sample is subjected to dimensionality reduction to obtain the hidden expression of the normal sample; the second self-encoder is generated using the hidden expression of the normal sample Initialize the memory module in and use the training sample to train the second self-encoder; input the test sample to the trained second self-encoder to obtain a reconstructed sample; use the test sample and The reconstructed sample is calculated to obtain a defect mask, and the technical solution is to determine whether the test sample has a defect according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com