Triple rod of power transmission transition line

A technology of connecting rods and lines, applied in the installation of overhead lines/cable equipment, electrical components, cables, etc., can solve the problems of long cycle time and high construction cost, and achieve the effect of simple structure and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

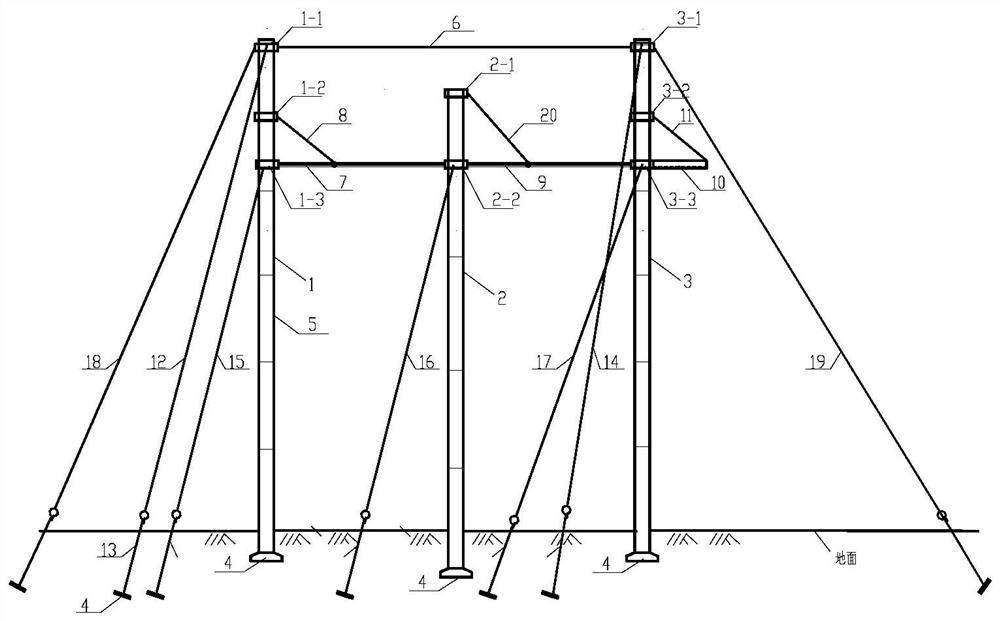

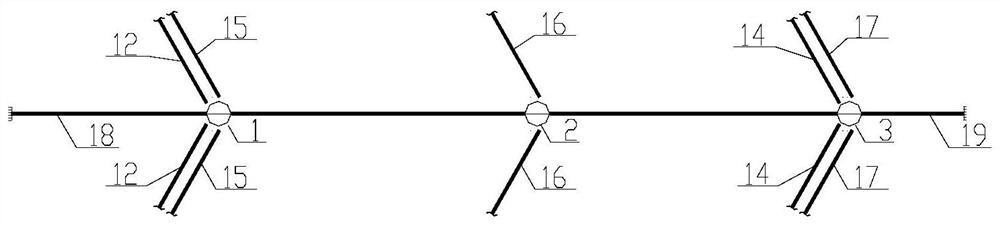

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] Refer to attached Figure 1-2 , this embodiment includes a three-link body, the three-link body is fixed on the ground through a chassis 4, and the three-link body includes outer corner bars 1, middle bars 2 and inner corner bars 3 arranged in a straight line at a certain distance. The outer corner bar 1, the middle bar 2 and the inner corner bar 3 are all made of multi-section prestressed reinforced concrete bar sections 5. The outer corner bar 1 and the inner corner bar 3 have the same structure, and are symmetrically arranged around the center bar 2, wherein the outer corner bar 1 is arranged outside the corner of the line, and the inner corner bar 3 is arranged inside the corner of the line.

[0027] The lower ends of the outer corner bar 1 , middle bar 2 and inner corner bar 3 are respectively buried in the soil through the chassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com